Anti-cracking detection method for low-smoke halogen-free sheath material

A technology of low-smoke halogen-free sheath and detection method, which is used in measuring devices, analytical materials, instruments, etc., can solve the problem of poor cracking resistance of low-smoke halogen-free flame retardant cables, not conforming to the actual laying conditions on site, and affecting customer products. Quality and other issues, to achieve the effect of speeding up anti-cracking detection time, effective detection, and preventing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further elaborated below in conjunction with specific embodiments.

[0051] The low-smoke and halogen-free cable sheathing material involved in the present invention has excellent flame retardancy, less smoke and no corrosive gas escape when burning, but the low-smoke and halogen-free cable sheathing material has poor crack resistance and is easy to be used in practical applications. In the event of cable cracking, it is necessary to test the material to determine whether there is a risk of cracking in the material.

[0052] Example of specific implementation steps:

[0053] 1. Equipment involved

[0054] Plastic refining machine, molding machine, pointer thickness gauge, scoring device, brass sample holder with groove, hard glass test tube, constant temperature bath.

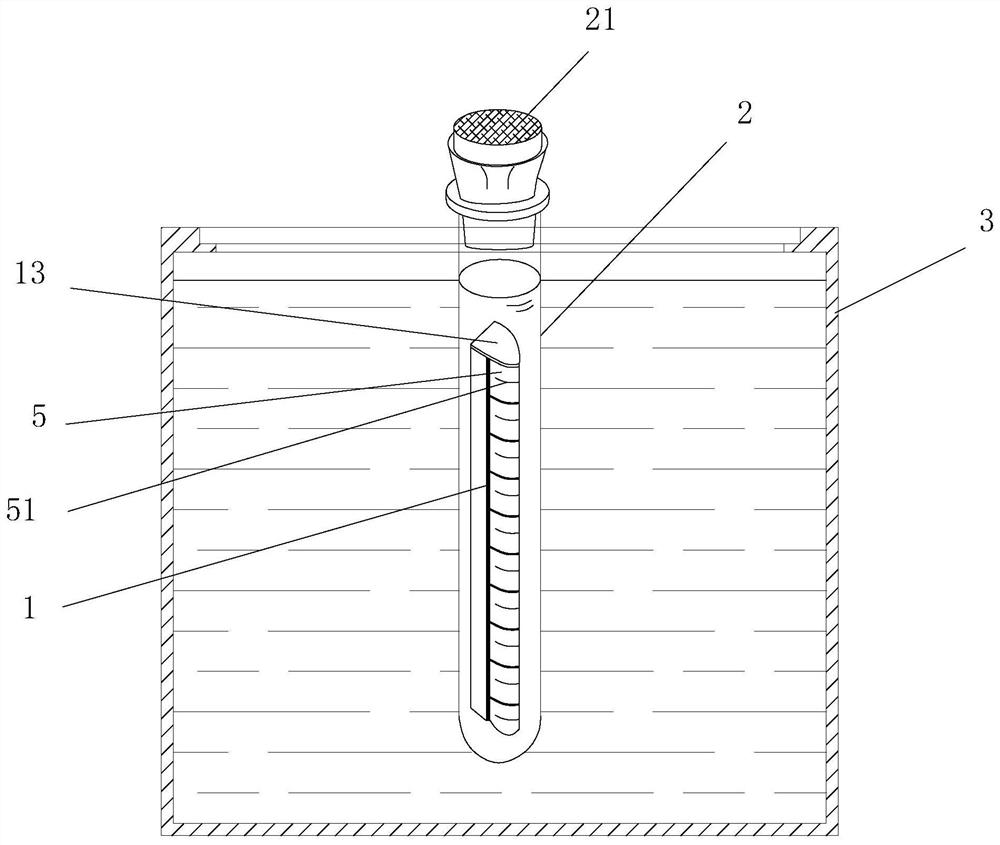

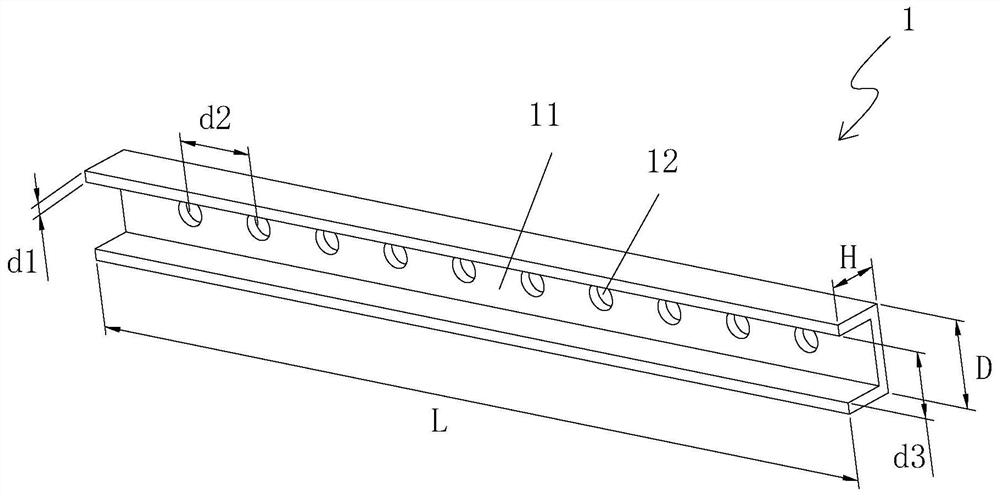

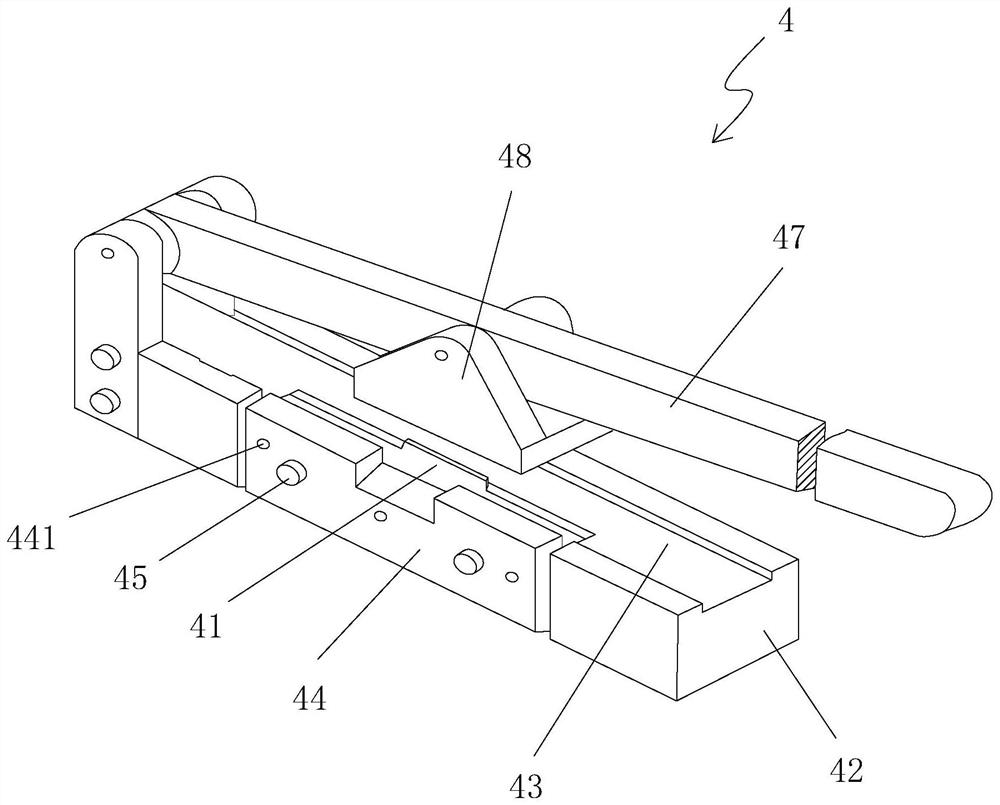

[0055] Among them, the low-smoke and halogen-free sheath material anti-cracking detection device specifically adopted in the present invention has a test rack 1 , a test t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com