A method of reducing load and prying to prevent rockburst in coal seam group with large dip angle

A technology of rock burst and coal seam group, which is applied in ground mining, earthwork drilling, underground mining, etc., can solve the problems of frequent rock burst, high cost, shallow relative stress concentration area, etc., to improve the effect of pressure relief, Effects of cost reduction and impact risk reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

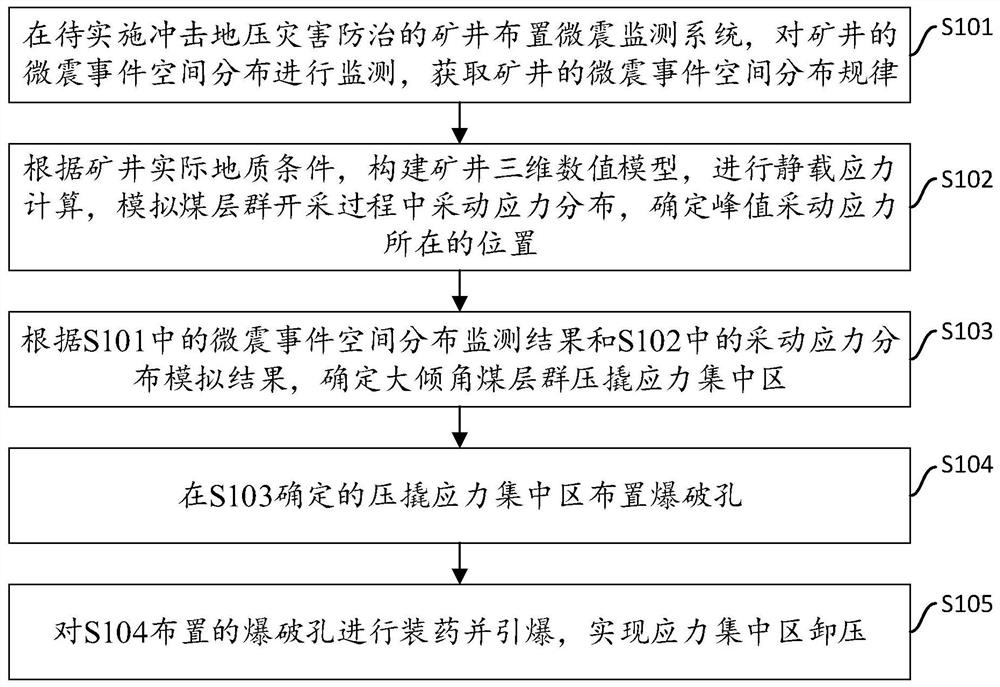

[0030] This embodiment provides a method for reducing load and prying to prevent and control rockburst of coal seam groups with large dip angles, which is used for precise and targeted pressure relief of coal seam groups with large dip angles. The method determines the stress concentration area and implements targeted blasting engineering to improve the pressure relief effect and reduce the risk of impact, and is especially suitable for the prevention and control of rock burst in the mining process of large-dip coal seam groups. The execution flow of this method is as follows figure 1 shown, including the following steps:

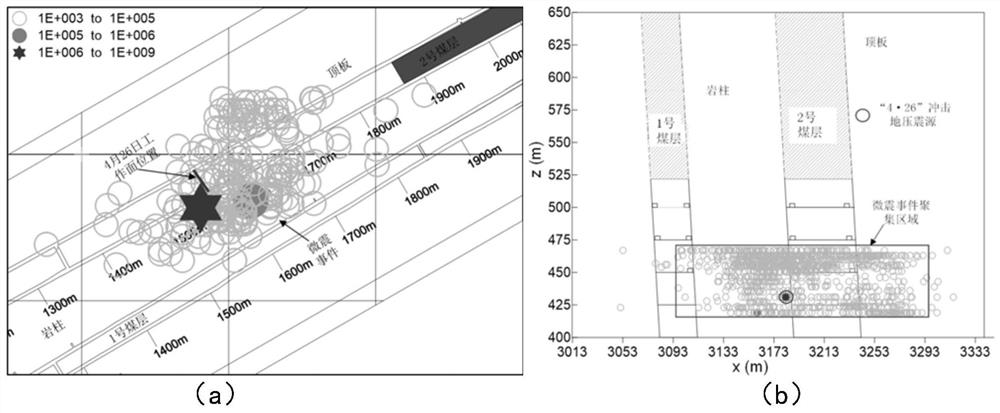

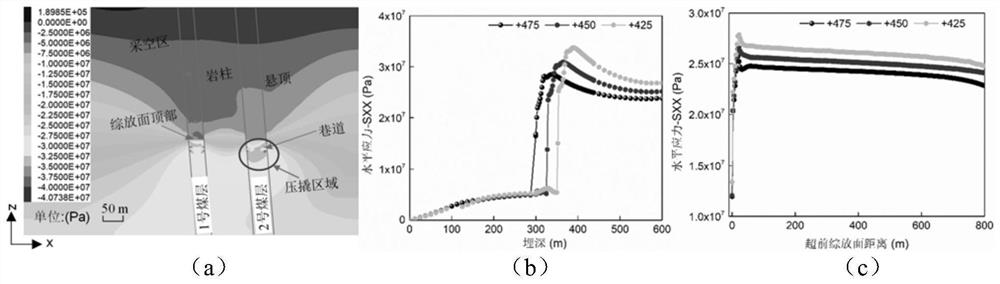

[0031] S101, deploying a microseismic monitoring system in mines to be implemented for prevention and control of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com