Building outer wall decorative plate fastener and mounting method thereof

A technology for building exterior walls and decorative panels, which is used in construction, building construction, covering/lining, etc., can solve problems such as waste of resources, aging, and affect aesthetics, achieve high work and operation efficiency, enhance anti-deformation ability, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

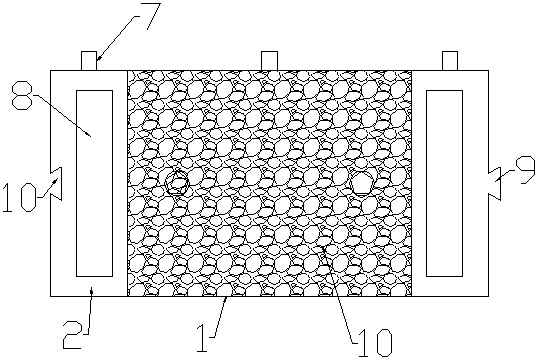

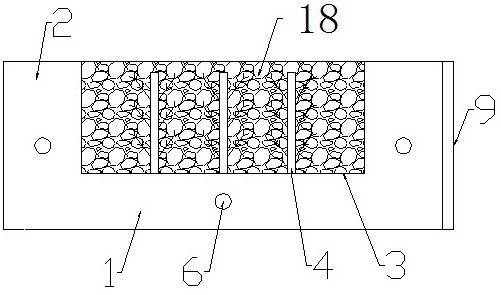

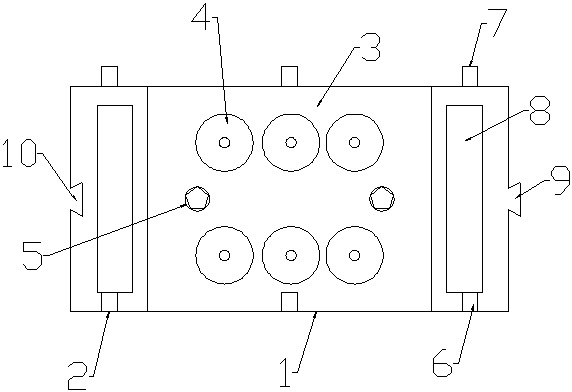

[0026] Such as figure 1 , 2 , 3, 4, , 5, 6, 7, 8, 9, and 10, a building exterior wall decorative panel fastener includes a base piece and a decorative panel buckled with the base piece, and the base piece is The cross-section is a "凵"-shaped block structure, and a connecting slot 8 is opened on the outer surface of the base part. The decorative plate is a block-shaped structure with a "凵"-shaped cross-section. The length of the base part is the same as the length of the decorative plate. Equal, the width of the base part is equal to the width of the decorative panel, the thickness of the base part is not less than the thickness of the decorative panel, the inner side of the decorative panel is provided with a connecting block 12 that matches the connecting slot 8, and the decorative panel The base piece is clamped with the base piece through the connection block 12 and the connection slot 8. The base piece is fixedly connected with the building exterior wall through the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com