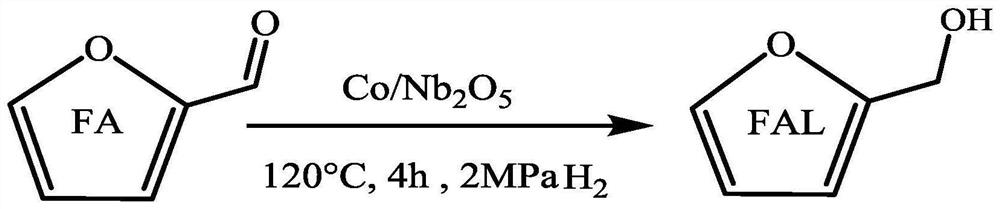

Synthetic method and application of magnetic catalyst for preparing furfuryl alcohol through catalytic hydrogenation of furfural

A technology for catalytic hydrogenation and metal catalysts, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. Low cost, low equipment requirements, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 0.004mol of Co(NO 3 ) 2 ·6H 2 O is dissolved in 0.2 mol of water, and its aqueous solution is added with 0.01 mol of Al 2 o 3 After stirring overnight, dry it in a drying oven at 100°C, bake it in a muffle furnace at 500°C for 4 hours, and then reduce it in a tube furnace at 500°C for 4 hours before use to obtain the corresponding monometallic catalyst.

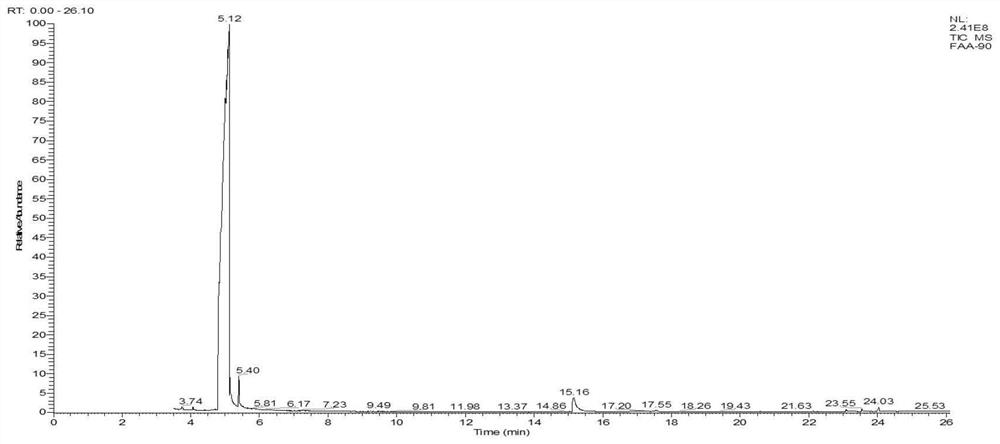

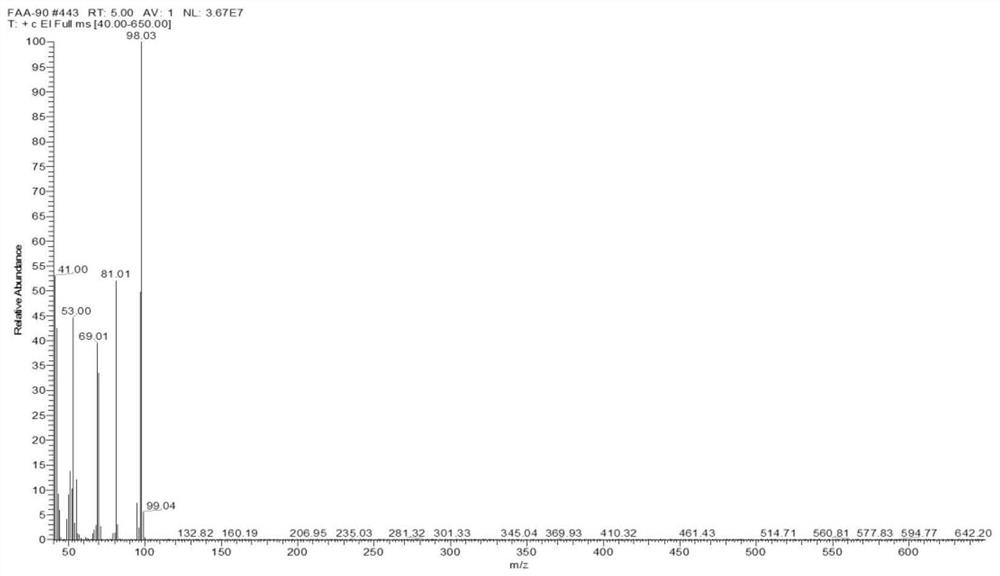

[0026] Take by weighing 0.2g furfural and 5mL water and put it into the 40mL reactor, then add 0.1g catalyst (Co-Al 2 o 3 , where Al 2 o 3 as a carrier, the active ingredient is Co, and the weight percentage of the active ingredient Co is 20%). Replace the air in the kettle with hydrogen for three to four times, then fill it with hydrogen until the initial pressure is 2MPa, turn on the stirring device at 400rpm, heat to 120°C for 4 hours and then cool down. The product is separated by a magnet and extracted with ethyl acetate. Gas chromatography mass spectrometry (GC-MS, ThermoScientific) was used for qu...

Embodiment 2

[0028] Weigh 0.004mol of Co(NO 3 ) 2 ·6H 2 O is dissolved in 0.2 mol of water, and its aqueous solution is added to 0.004 mol of Nb 2 o 5 After stirring overnight, dry it in a drying oven at 100°C, calcinate at 500°C for 4 hours, and reduce it in a tube furnace at 500°C with hydrogen for 4 hours before use to obtain the corresponding monometallic catalyst.

[0029] Take by weighing 0.2g furfural and 5mL water and put it into the 40mL reactor, then add 0.1g catalyst (Co-Nb 2 o 5 , where Nb 2 o 5 as a carrier, the active ingredient is Co, and the weight percentage of the active ingredient Co is 20%). Replace the air in the kettle with hydrogen for three to four times, then fill it with hydrogen until the initial pressure is 2MPa, turn on the stirring device at 400rpm, heat to 120°C for 4 hours and then cool down. The product is separated by a magnet and extracted with ethyl acetate. Gas chromatography mass spectrometry (GC-MS, ThermoScientific) was used for qualitative a...

Embodiment 3

[0031] The corresponding monometallic catalyst was prepared by the method of Example 2 for future use.

[0032]The reaction was carried out in the same manner as in Example 2, except that the reaction temperature was 100°C. The results obtained from the reaction are: the conversion rate of furfural is 98.52%, and the yield of furfuryl alcohol is 66.72%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com