Large-interlayer-spacing monodisperse nano hard carbon material as well as synthesis method and application thereof

A synthesis method, monodisperse technology, applied in nanocarbon, nanotechnology, nanotechnology, etc., can solve the difficulty of meeting the requirements of commercialization of sodium-ion batteries, poor rate performance and cycle life, and low carbon yield of hard carbon materials, etc. problem, to achieve the effect of favorable adsorption and diffusion, short diffusion path and full utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of a nano-hard carbon material with monodisperse morphology of large interlayer spacing, comprising the following steps:

[0027] (1) Dissolve xylose in deionized water, stir until uniform, prepare a solution with a concentration of 0.73M, the stirring speed is 500rpm, the stirring time is 0.5h, the stirring temperature is 30°C, and the solution is heated to 180°C Carry out dehydration condensation reaction for 24h;

[0028] (2) The material obtained in step (1) is centrifuged and cleaned at a high speed, and vacuum-dried at a drying temperature of 60°C for 24 hours;

[0029] (3) The material obtained in step (2) is subjected to high-temperature carbonization under an argon atmosphere in a high-temperature furnace; the temperature is 1200° C., the carbonization time is 3 hours, and the heating rate is 5° C. / min; the argon flow rate is 200 sccm to obtain a large layer Nanoscale hard carbon materials with monodisperse spacing.

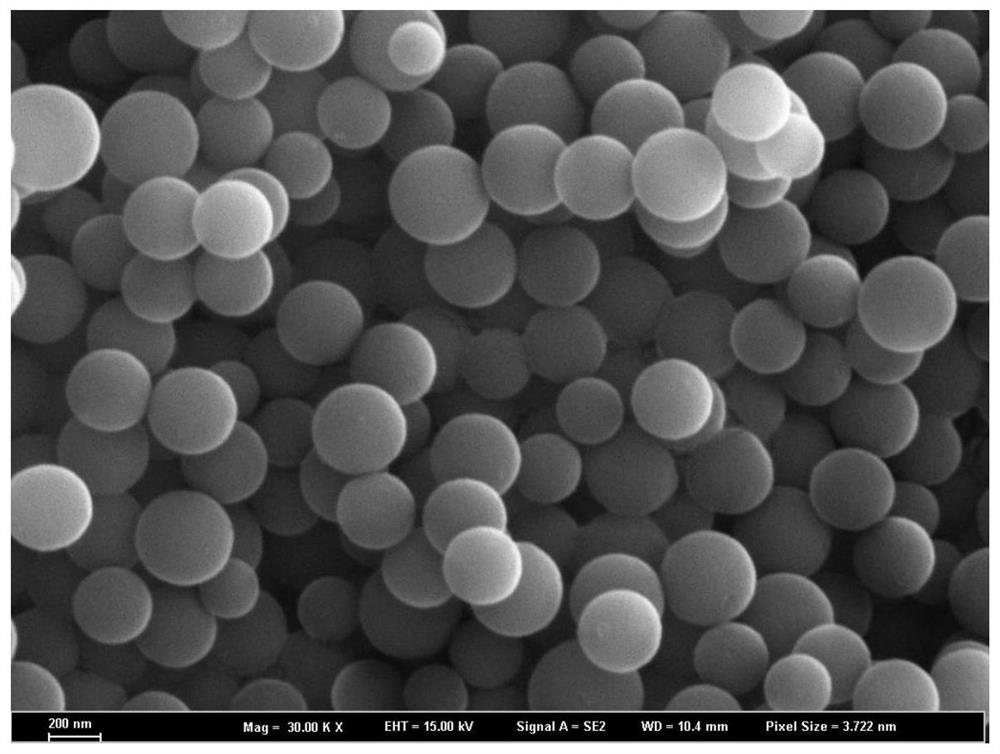

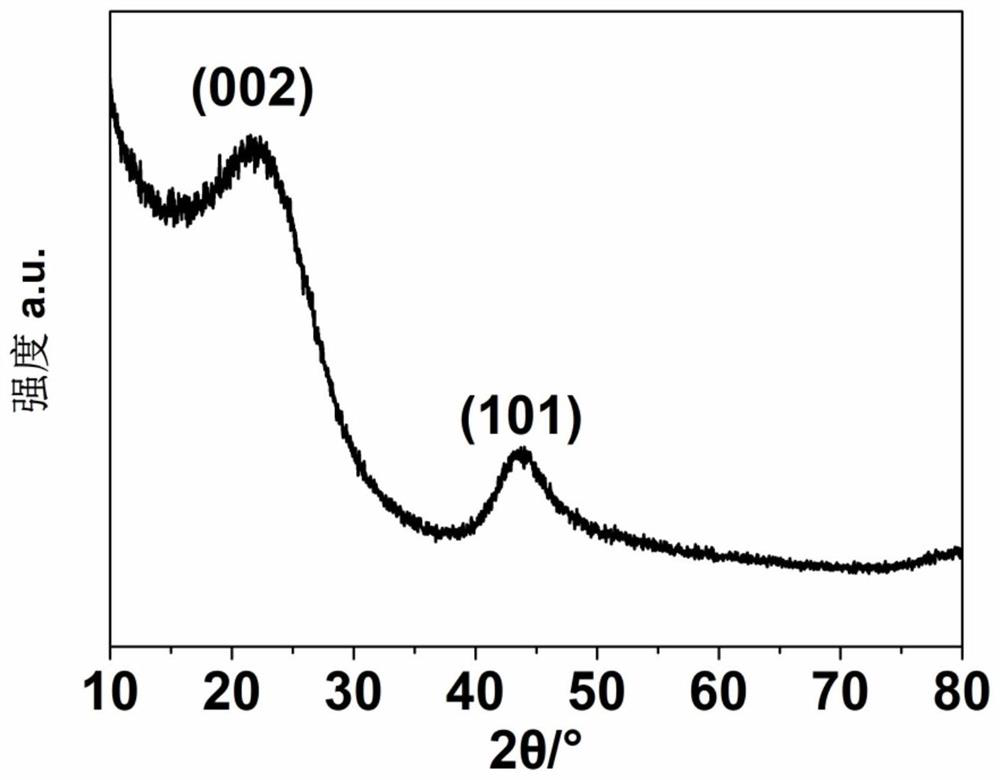

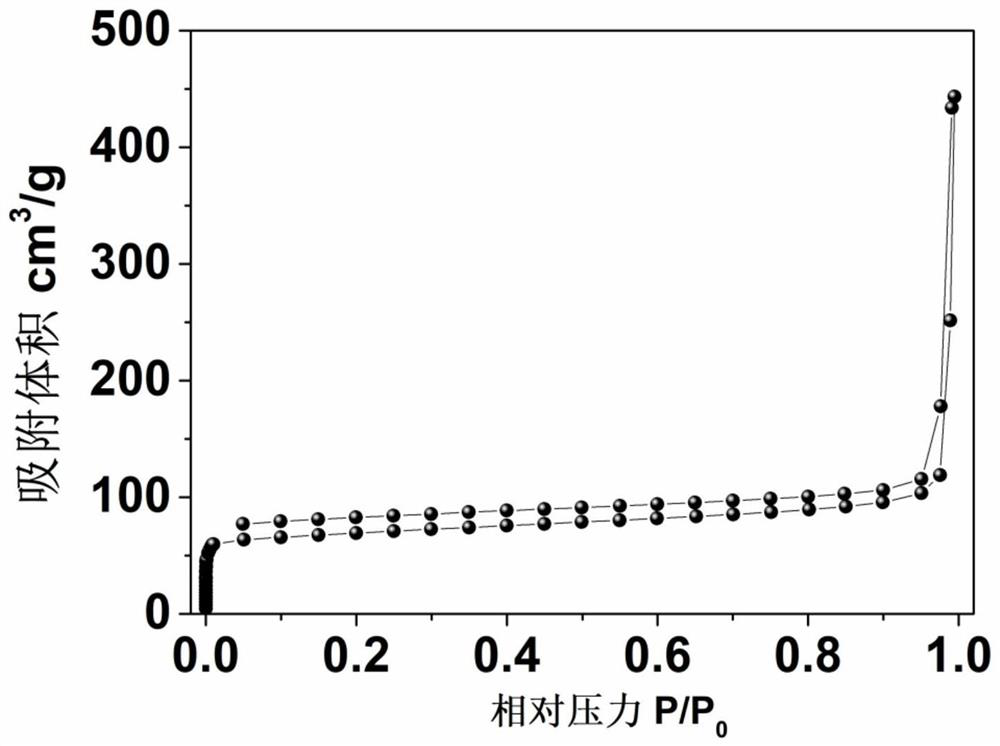

[0030] figure 1 The...

Embodiment 2

[0035] A kind of preparation method of the monodisperse nano-hard carbon material of large interlayer distance, comprises the following steps:

[0036] Dissolve xylose in deionized water, stir until uniform, prepare a solution with a concentration of 0.73M, the stirring speed is 500rpm, the stirring time is 0.5h, the stirring temperature is 30°C, and the solution is heated to 190°C for dehydration condensation Reaction 24h;

[0037] (2) The material obtained in step (1) is centrifuged and cleaned at a high speed, and vacuum-dried at a drying temperature of 60°C for 24 hours;

[0038] (3) The material obtained in step (2) is subjected to high-temperature carbonization under an argon atmosphere in a high-temperature furnace; the temperature is 1200° C., the carbonization time is 3 hours, and the heating rate is 5° C. / min; the argon flow rate is 200 sccm to obtain a large layer Nanoscale hard carbon materials with monodisperse spacing.

Embodiment 3

[0040] A kind of preparation method of the monodisperse nano-hard carbon material of large interlayer distance, comprises the following steps:

[0041] Dissolve xylose in deionized water, stir until uniform, prepare a solution with a concentration of 0.73M, the stirring speed is 500rpm, the stirring time is 0.5h, the stirring temperature is 30°C, and the solution is heated to 200°C for dehydration condensation Reaction 24h;

[0042] (2) The material obtained in step (1) is centrifuged and cleaned at a high speed, and vacuum-dried at a drying temperature of 60°C for 24 hours;

[0043] (3) The material obtained in step (2) is subjected to high-temperature carbonization under an argon atmosphere in a high-temperature furnace; the temperature is 1200° C., the carbonization time is 3 hours, and the heating rate is 5° C. / min; the argon flow rate is 200 sccm to obtain a large layer Nanoscale hard carbon materials with monodisperse spacing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com