Pneumatic stock line conveying system

A technology of conveying system and sending system, which is applied in the direction of conveyor, conveying bulk materials, transportation and packaging, etc. It can solve the problems of inability to realize long-distance transportation, small conveying capacity of traditional pipe chains, and inflexible pipe layout, etc., and achieve material saving Low cost, flexible pipe layout, and reduced difficulty in construction operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

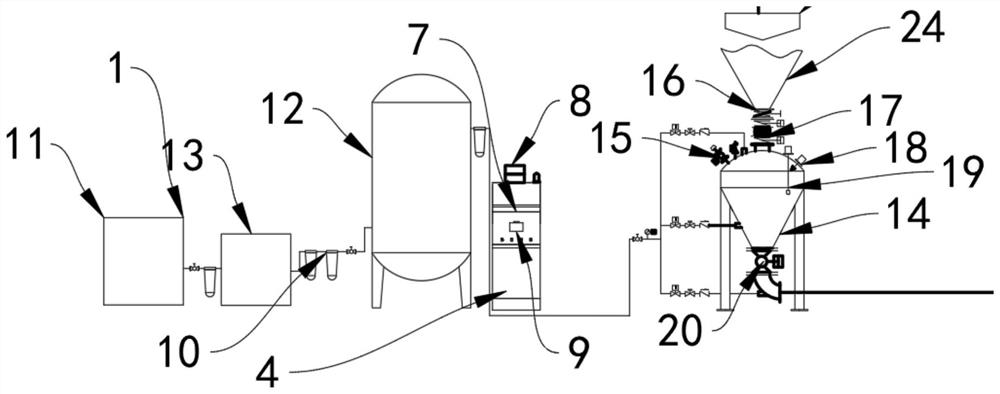

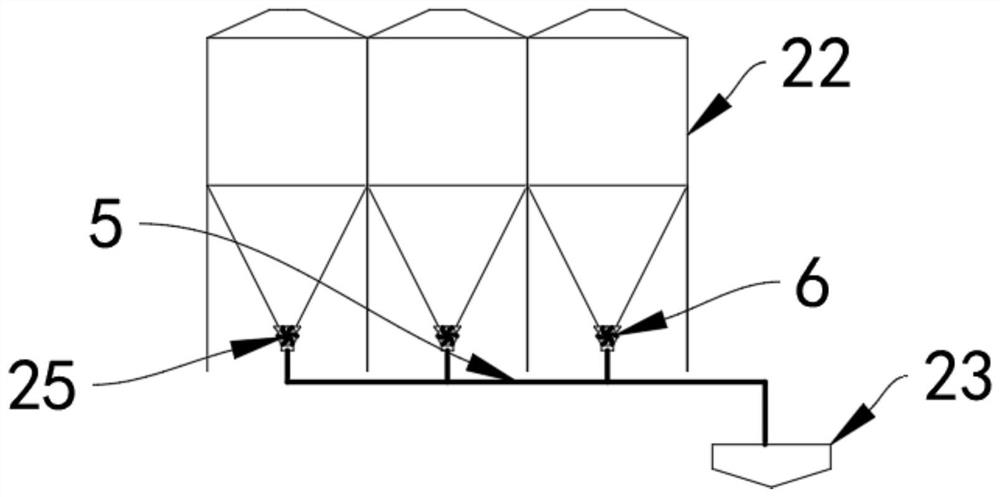

[0025] see Figure 1-5 , an embodiment provided by the present invention: a pneumatic material line conveying system, including a sending system 1, a conveying system 2, a blanking system 3, and a control system 4, characterized in that: one side of the sending system 1 is equipped with a pneumatic machine 11, one end of the conveying system 2 is provided with a conveying pipeline 26, the interior of the blanking system 3 is provided with an end buffer 31, and the interior of the control system 4 is provided with a control cabinet 8. The pipe is connected to the gas storage tank 12, and the gas storage tank 12 is connected to the freeze dryer 13 with a high-pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com