A liquid batching machine and its working method

A working method and batching machine technology, applied in home appliances, applications, kitchen utensils, etc., can solve problems such as poor accuracy and consistency, inability to work independently, and inability to cooperate with each other, so as to enhance safety, improve accuracy and Accuracy, the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention is described in detail through the following embodiments. However, those skilled in the art understand that the following specific implementation methods do not limit the protection scope of the present invention, and any improvements and changes made on the basis of the present invention are within the protection scope of the present invention.

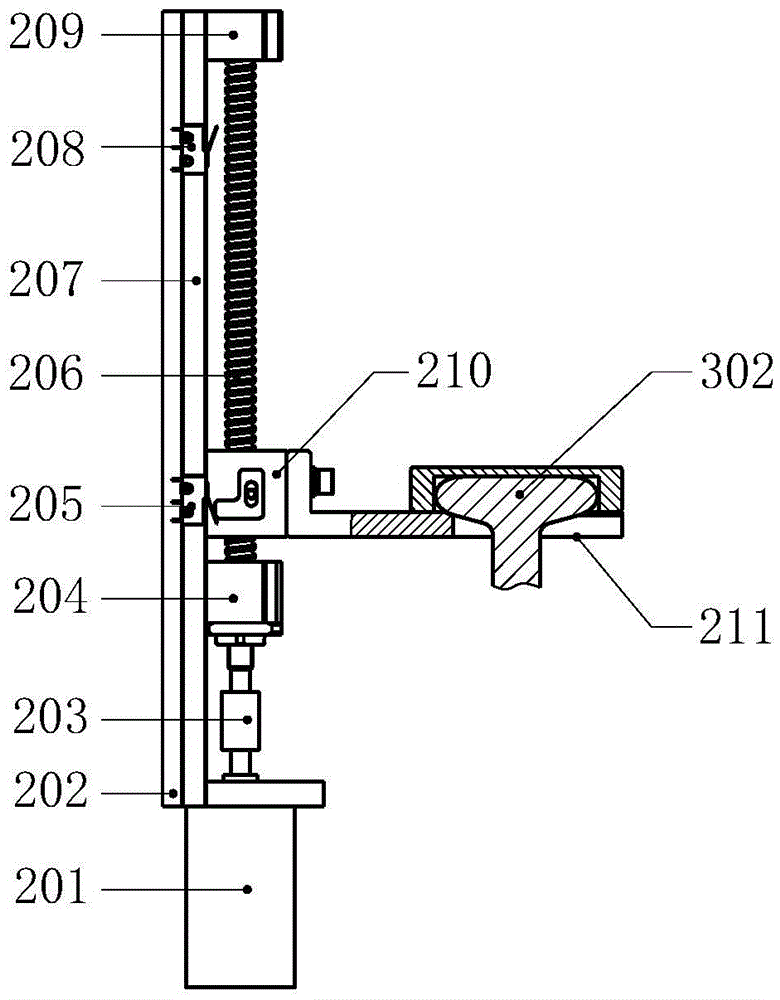

[0071] The invention discloses a liquid batching machine, comprising a transmission mechanism, a batching unit and a material storage system, the batching unit includes a piston, the push-pull movement of the piston is controlled by the transmission mechanism; the storage system includes at least one A storage unit and at least one disconnect switch.

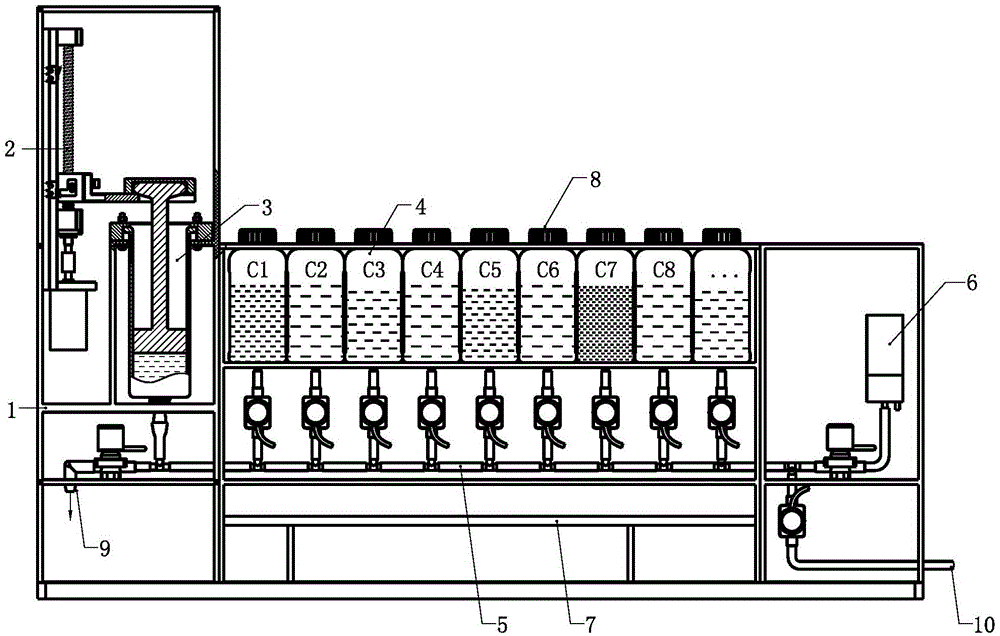

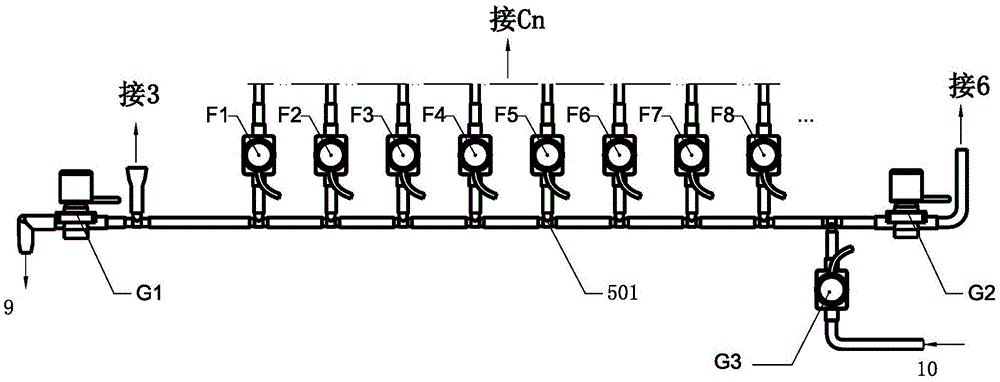

[0072] Such as figure 1 As shown, the liquid batching machine specifically includes a frame 1, a transmission mechanism 2, a batching unit 3, a material storage system 4, a pipeline system 5, an air pump 6 and a control module 7, wherein each part is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com