Hardware fitting machining, punching, inspecting and screening method

A screening method and technology for accessories, applied in metal processing, metal processing equipment, chemical instruments and methods, etc., can solve problems such as easy detection errors, low efficiency of accessories detection and screening, and inability to separate hole sizes for screening, etc. Novel and simple, simple detection and screening, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

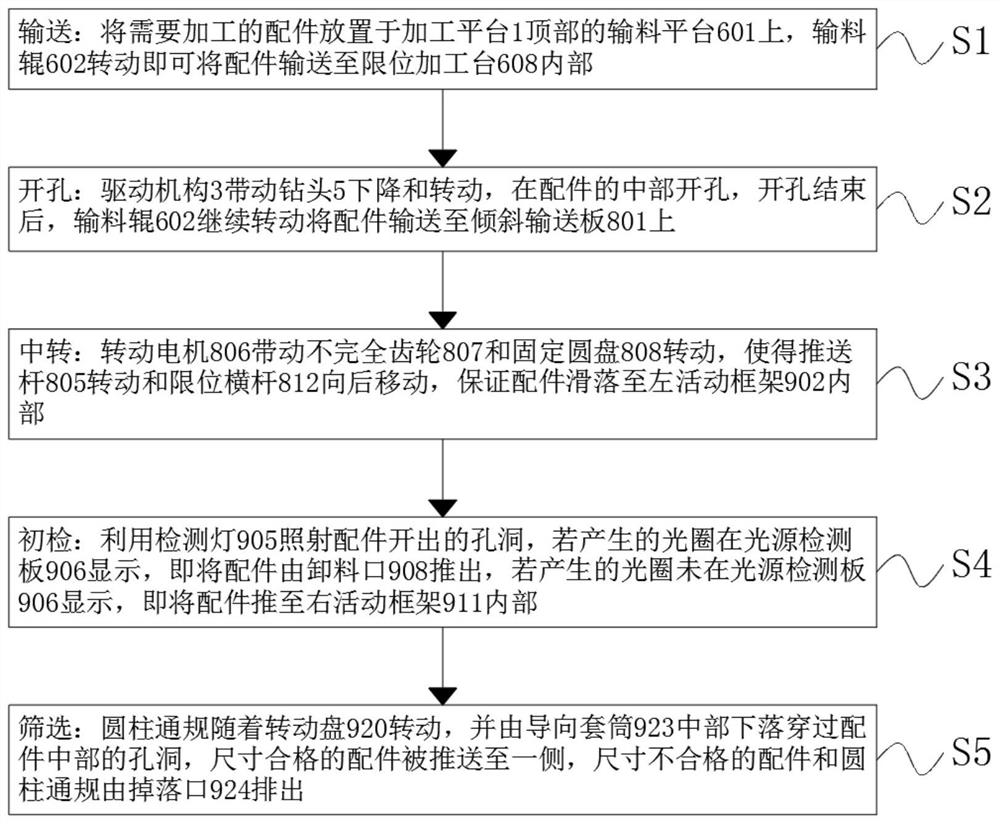

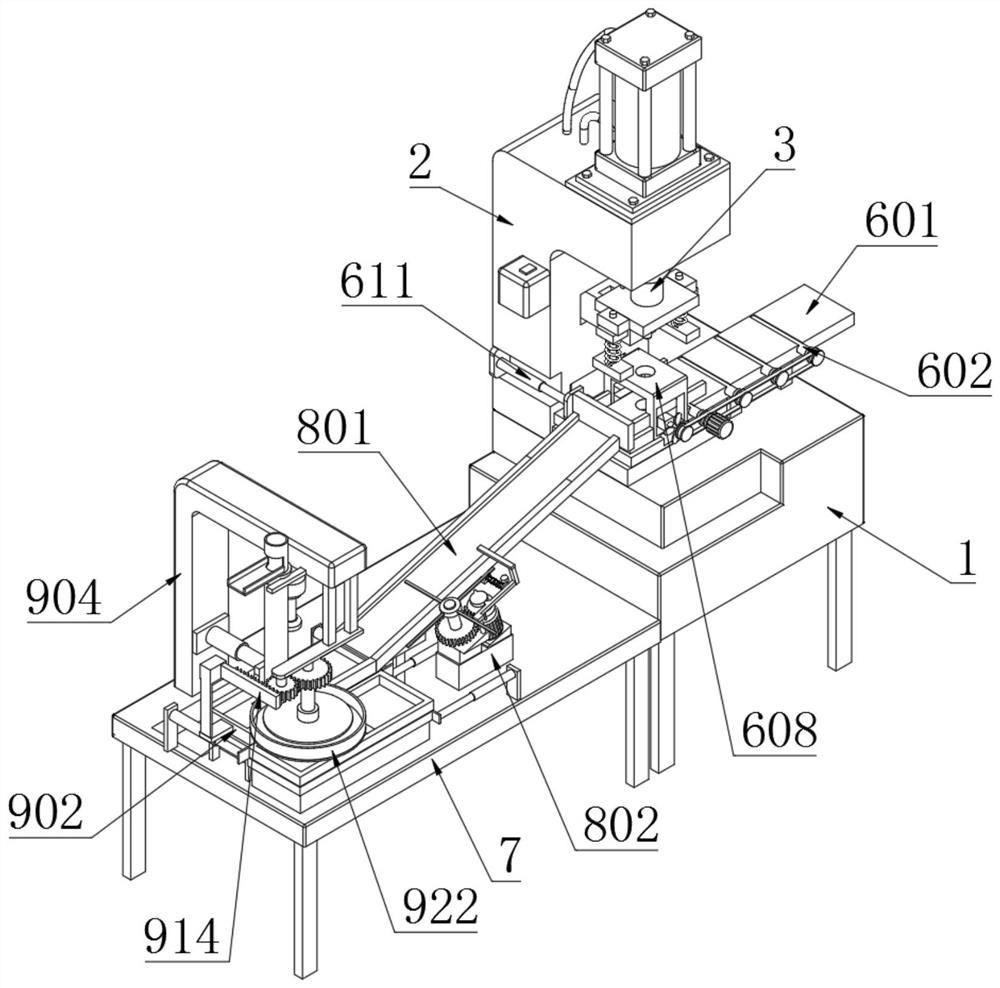

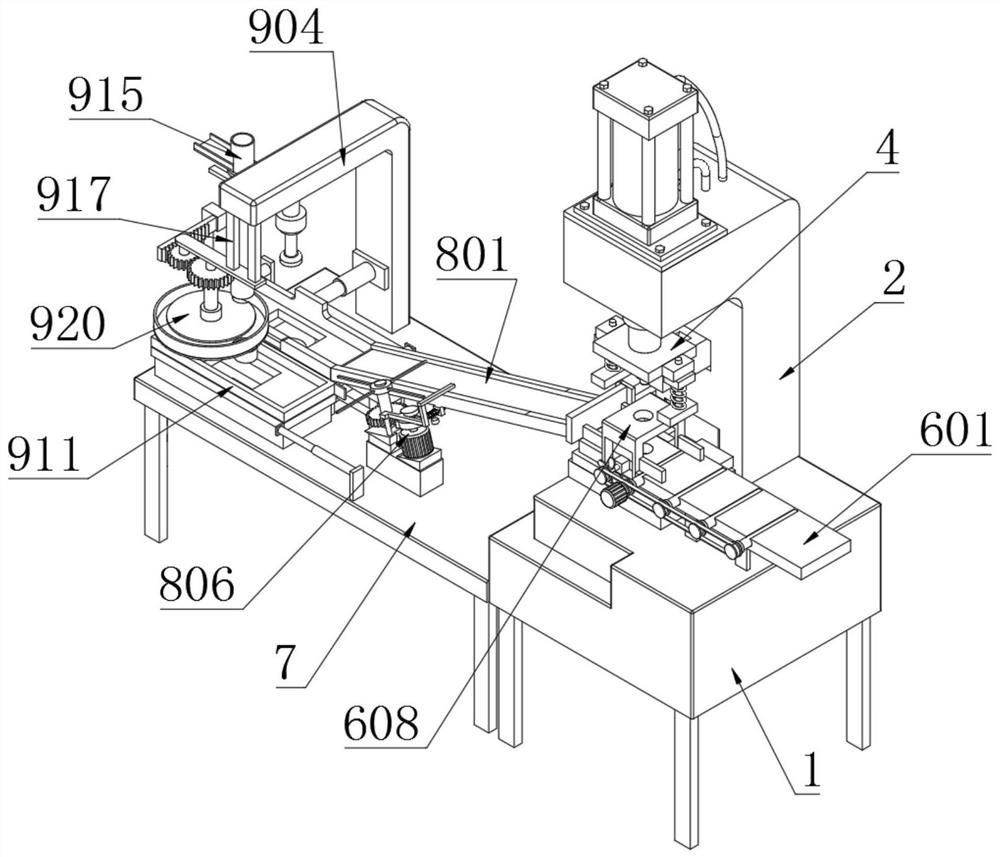

[0039] Example: such as Figure 1-4 As shown, the present invention provides a technical solution, a method for processing holes and inspecting and screening hardware accessories, including the following steps:

[0040] S1: Conveying: place the accessories to be processed on the conveying platform 601 at the top of the processing platform 1, and the conveying roller 602 rotates to convey the accessories to the limit processing table 608;

[0041] S2: Hole opening: the driving mechanism 3 drives the drill bit 5 to descend and rotate, and to open a hole in the middle of the accessory. After the hole is completed, the feeding roller 602 continues to rotate to transport the accessory to the inclined conveying plate 801;

[0042] S3: transfer: the rotating motor 806 drives the incomplete gear 807 and the fixed disc 808 to rotate, so that the push rod 805 rotates and the limit cross bar 812 moves backward to ensure that the accessories slide down to the inside of the left movable fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com