Compound impact body, impact hydraulic formation equipment and impact hydraulic formation method

A technology of hydroforming and impact body, applied in the field of impact hydroforming equipment and impact hydroforming, composite impact body, can solve the problems of long time consumption, energy loss, complicated operation, etc., to achieve convenient replacement, improve forming performance, reduce energy The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

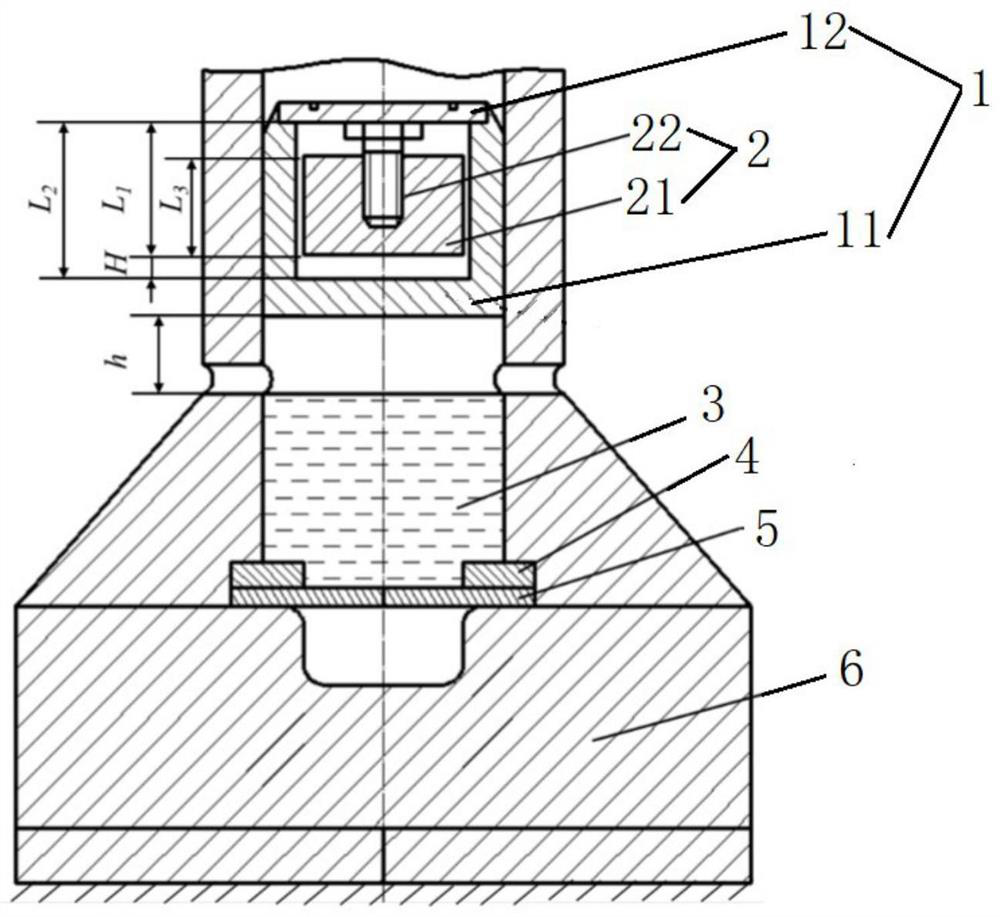

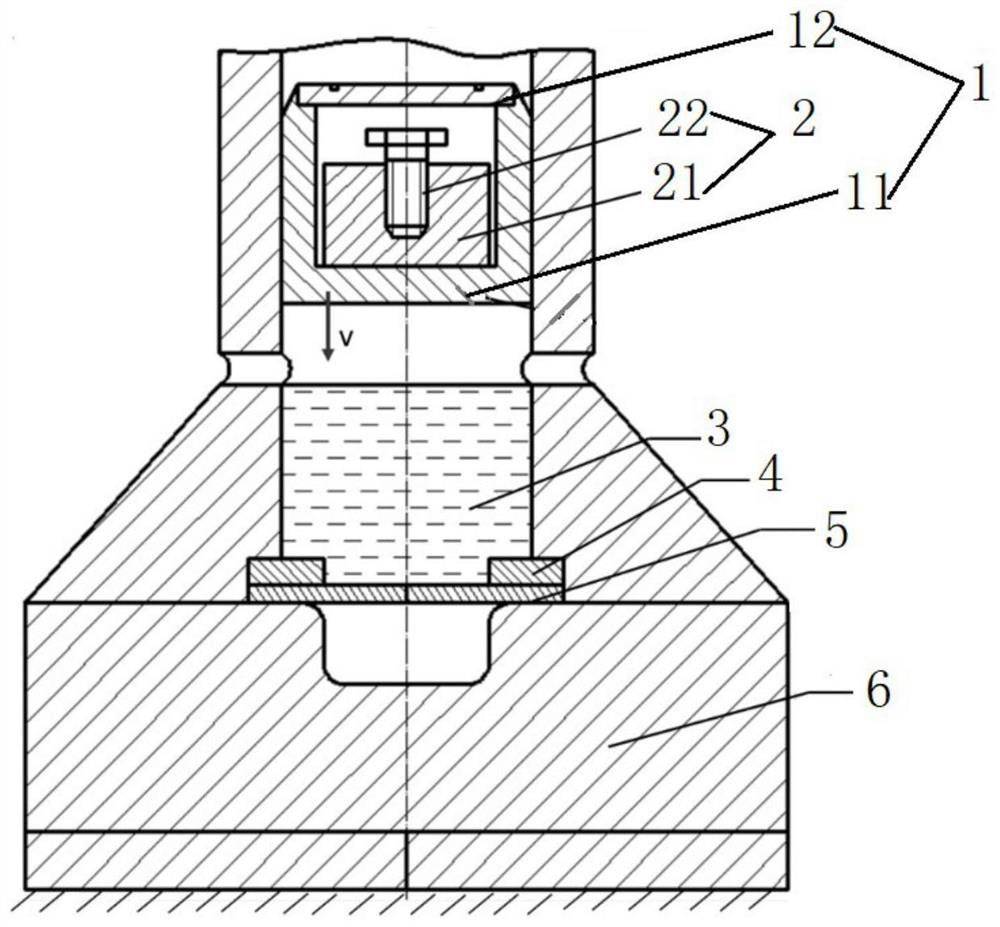

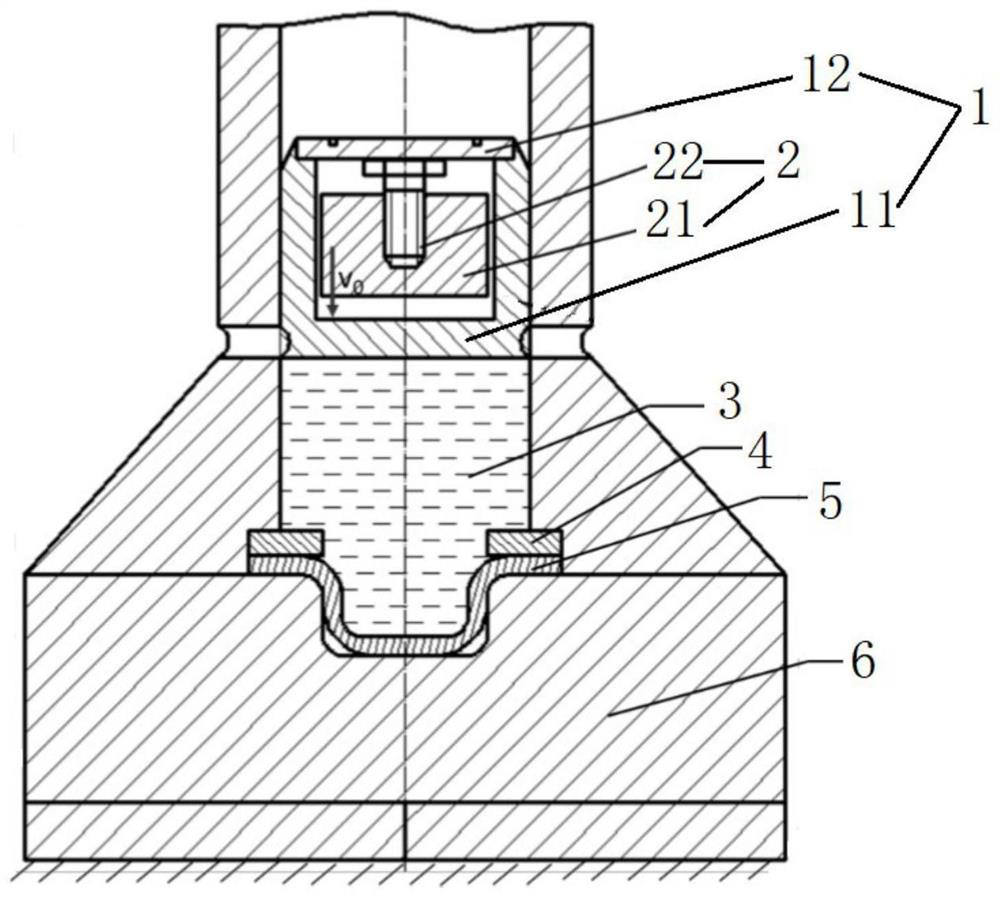

[0054] On the one hand, this embodiment provides a composite impact body for use in impact hydroforming equipment, such as Figure 1 to Figure 4 , Figure 6 to Figure 8 As shown, the composite impact body of this embodiment includes a primary impact structure 1 and a secondary impact structure 2; wherein, the primary impact structure 1 has a closed cavity. The secondary impact structure 2 is located in the closed cavity of the primary impact structure 1, and can move along the impact direction in the closed cavity (it can also move in the opposite direction of the impact direction in the closed cavity, that is, it can move in the closed cavity longitudinal movement in the body). Among them, in the process of impact hydroforming: after the primary energy is released, the composite impact body moves (see figure 2 ), when the primary impact structure 1 touches the liquid surface of the liquid chamber 3 and stops moving, the secondary impact structure 2 can continue to move alo...

Embodiment 2

[0058] Preferably, this embodiment proposes a composite impact body, compared with the previous embodiment, as Figure 1 to Figure 4 , Figure 6 to Figure 8 As shown, the present embodiment further designs the primary impact structure 1 as follows:

[0059] The primary impact structure 1 includes: a primary impact body 11 and a baffle 12 . Wherein, the primary impact body 11 has a groove structure; the baffle plate 12 is connected with the primary impact body 11, and is used to block the notch of the groove structure, so as to form a closed cavity of the primary impact structure 1 with the groove structure. Preferably, the baffle plate 12 is connected to the primary impact body 11 through fasteners, preferably through bolts.

[0060] Here, the composite impact body provided in this embodiment is designed by designing the primary impact structure 1 as a primary impact body 11 with a groove structure and a baffle plate 2 for blocking the notch of the groove structure. Placing...

Embodiment 3

[0062] Preferably, this embodiment proposes a composite impact body, compared with the previous embodiment, as Figure 1 to Figure 4 , Figure 6 to Figure 8 As shown, the present embodiment further designs the secondary impact structure 2 as follows:

[0063] The secondary impact structure 2 comprises a secondary impact body 21 and an adjustment device 22 . Wherein, the adjustment device 22 is connected with the secondary impact body 21, and is used to adjust the longitudinal distance H between the secondary impact structure 2 and the closed cavity (that is, the longitudinal length L of the closed cavity). 2 with the longitudinal length L of the secondary impact structure 1 Difference). Wherein, the longitudinal direction of the secondary impact structure 2 and the closed cavity 1 is parallel to the impact direction; the set distance is equal to the longitudinal separation distance H. Wherein, when the secondary impact structure 2 is in contact with the baffle plate 12 (or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com