Multifunctional processing system and method

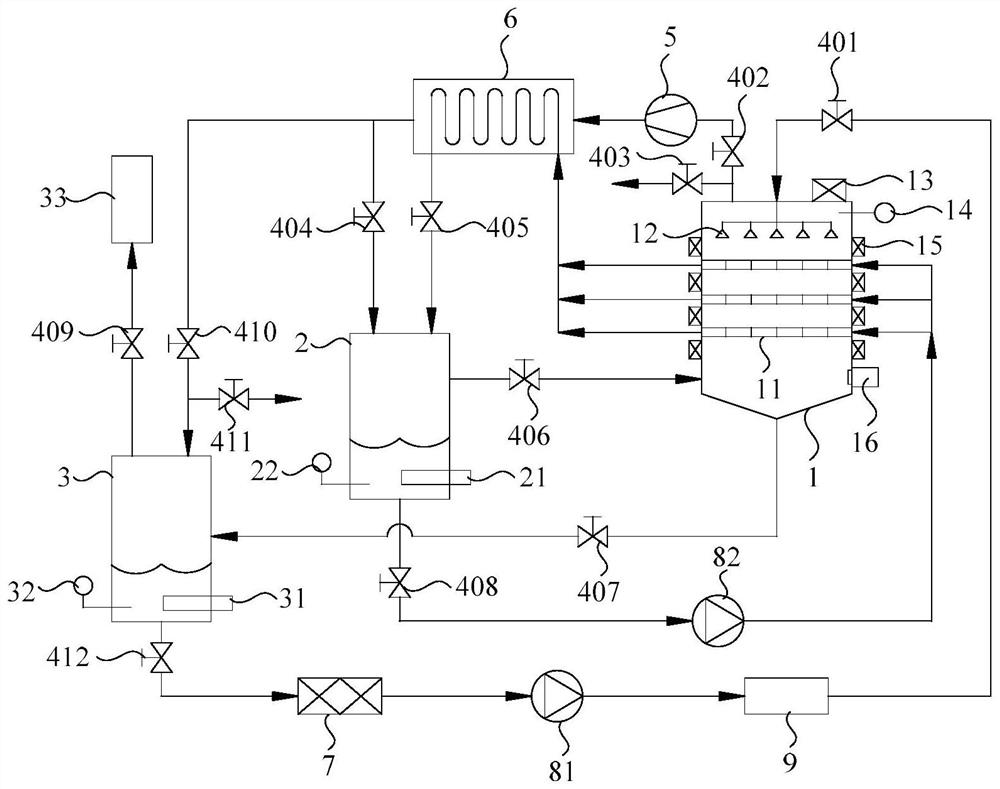

A multi-functional, subsystem technology, applied in the direction of making medicines into special physical or ingestible devices, lighting and heating equipment, dryers, etc., can solve the problem of inability to accurately control process parameters, complicated and Single and other problems, to achieve the effect of automatic operation, improve production efficiency, and achieve precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

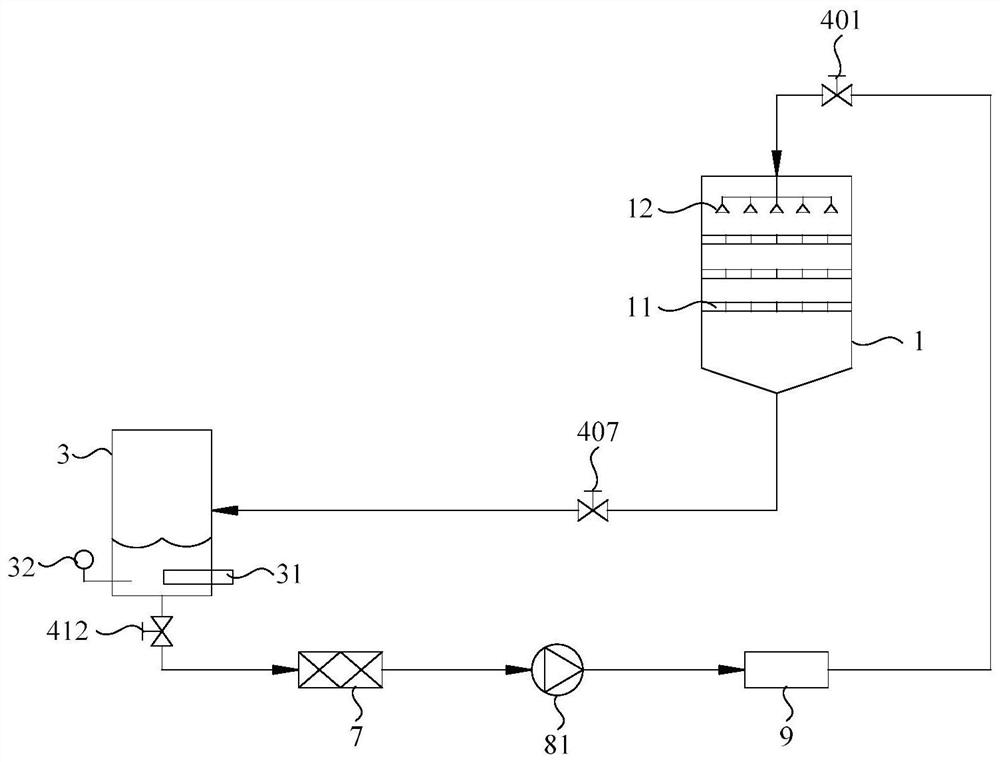

Embodiment 1

[0069] Embodiment 1, wine Polygonatum is processed:

[0070] First, add the prepared medicinal liquid solvent into the second tank body 3 to the required amount, then put the washed and dried Rhizoma Polygonatum into the tray 11, wherein the medicinal liquid solvent is preferably yellow rice wine, and the Rhizoma Polygonatum loading capacity of the tray 11 is 25-30kg / m2, the mass ratio of sealwort and medicinal liquid solvent is about 3:1-4:1, and the following processing techniques are gradually started.

[0071] (1) The first step is to start the infiltration function, spray circularly through the nozzle 12, and evenly spray the medicinal liquid solvent on the polygonatum on the tray 11, and the Polygonatum continuously absorbs the medicinal liquid solvent, through the second temperature sensor 32 and the second electric heating The tube 31 controls the temperature of the liquid medicine, and the infiltration temperature range is selected at 15-25° C. to achieve the best in...

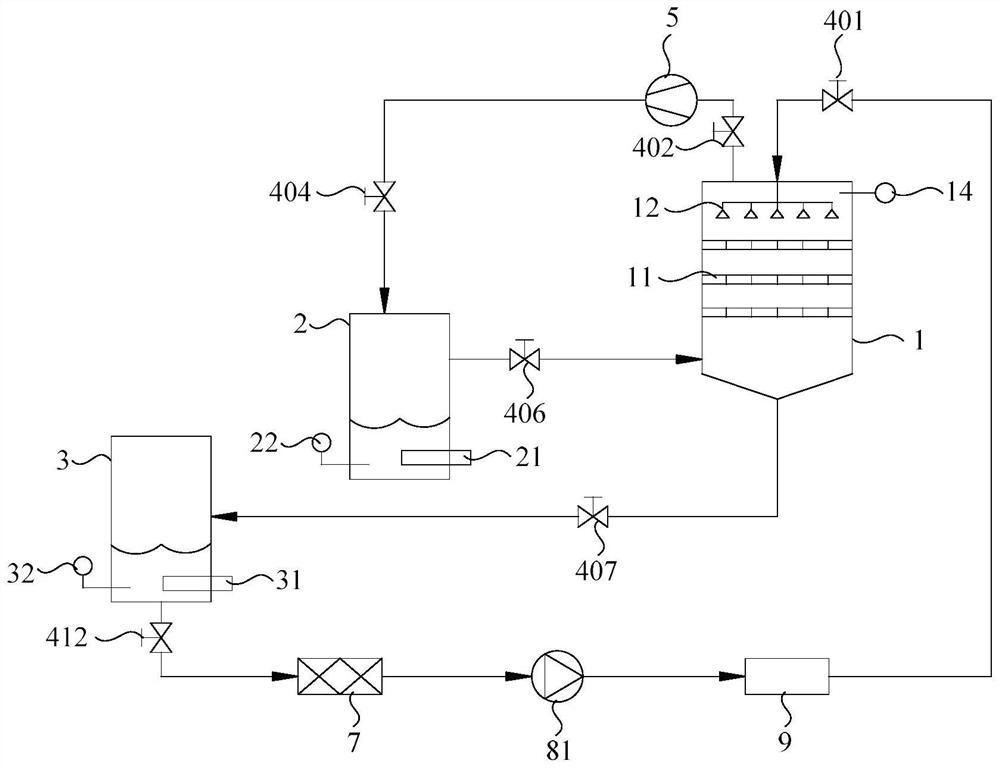

Embodiment 2

[0076] Embodiment 2, honeysuckle concocted:

[0077] First the cleaning solution is added to the required amount in the second tank body 3, then the preliminary cleaned honeysuckle is put into the tray 11, wherein the cleaning solution is preferably deionized water, and the TDS of the deionized water is controlled within 20ppm. The loading capacity of honeysuckle is 3-5kg / m2, and the following processing techniques are gradually started.

[0078] (1) In the first step, the cleaning function is started, and the cleaning solution is evenly sprayed on the honeysuckle on the tray 11 by circulating spraying, and the cleaning solution continuously absorbs the pesticide residues on the honeysuckle, and is heated by the second temperature sensor 32 and the second electric heater. Pipe 31 controls the temperature of the cleaning liquid. The cleaning temperature range is selected at 20-30°C to achieve the best cleaning effect. Turn on the magnetic field generator on the cleaning pipelin...

Embodiment 3

[0080] Embodiment 3: Fresh-keeping mushrooms:

[0081] First, the cleaning liquid is added to the required amount in the second tank body 3, and then the preliminarily cleaned shiitake mushrooms are put into the tray 11, wherein the cleaning liquid is preferably deionized water, and the TDS of the deionized water is controlled within 20ppm. The shiitake mushrooms on the tray 11 The loading capacity is 6-8kg / m2, and the following processing techniques are gradually started.

[0082] (1) In the first step, the cleaning function is started, and the cleaning liquid is evenly sprayed on the shiitake mushrooms on the tray 11 through circulating spraying, and the cleaning liquid continuously absorbs the pesticide residues on the shiitake mushrooms, and is heated by the second temperature sensor 32 and the second electric heater. Pipe 31 controls the temperature of the cleaning liquid. The cleaning temperature range is selected at 20-30°C to achieve the best cleaning effect. Turn on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com