A corrugated bridge with wind circulation system

A circulating system and corrugated bridge technology, applied in electrical components and other directions, can solve the problems of increasing line resistance and loss, reducing cable service life, reducing power utilization, etc., to reduce resistance and loss, improve utilization, and heat dissipation. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

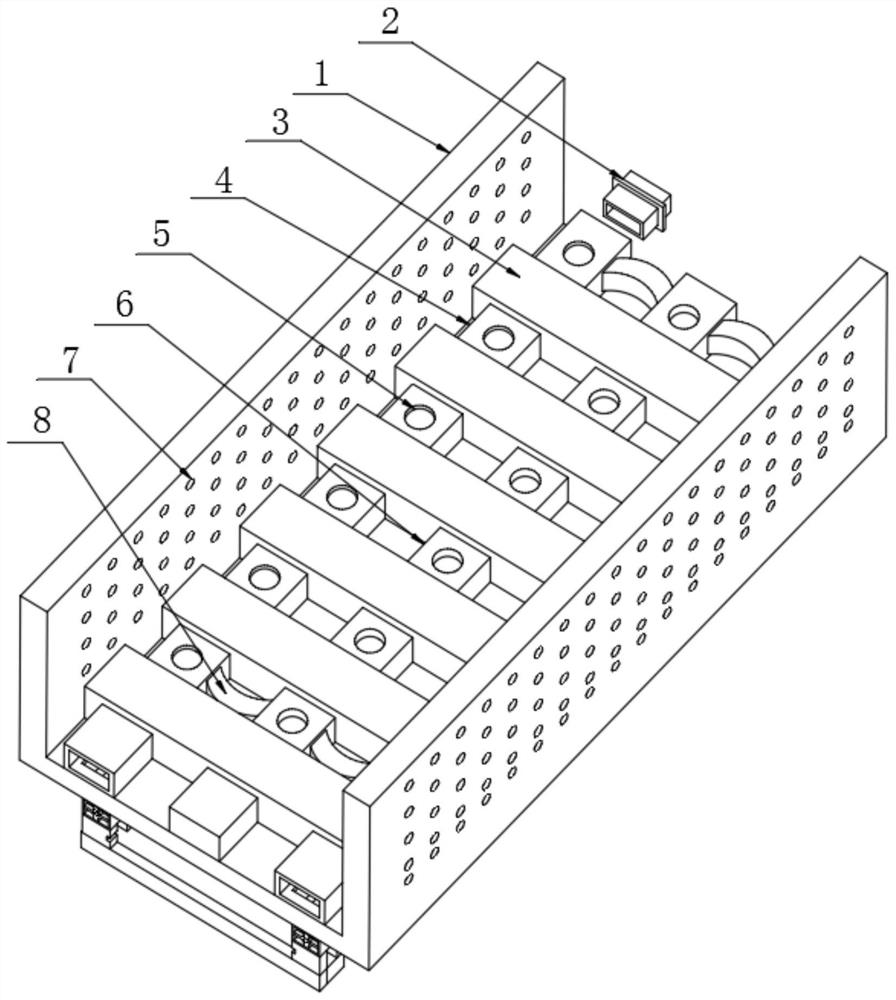

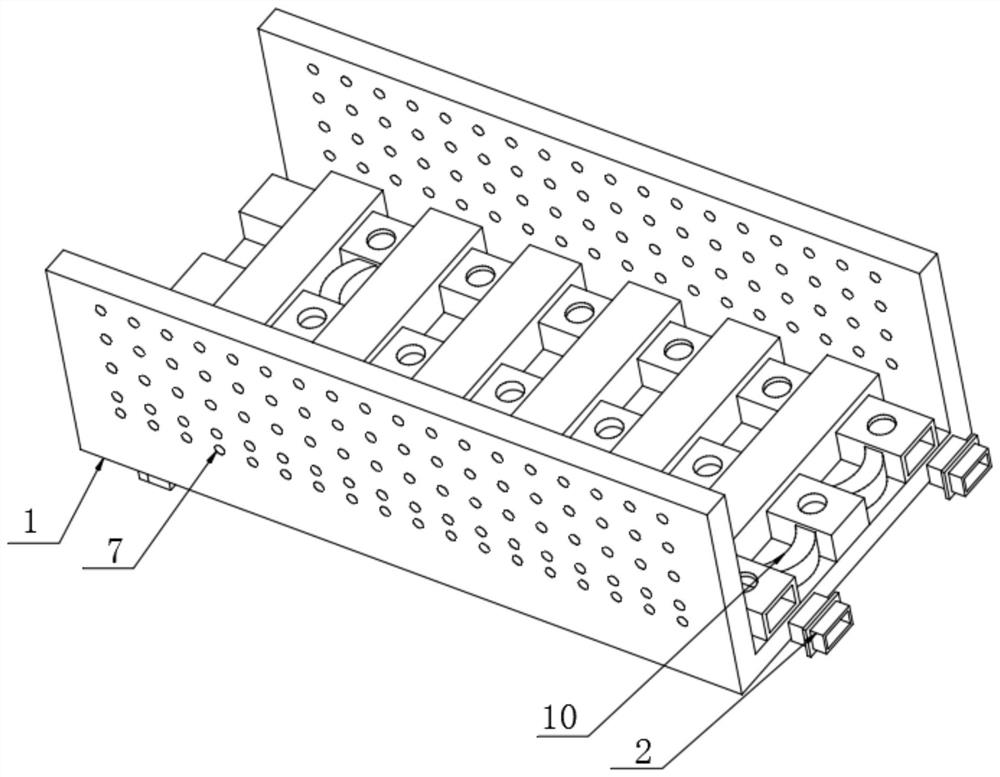

[0034] Example 1, with reference to the attached Figure 1-10 , The present invention provides a corrugated bridge frame with a wind power circulation system, comprising a bridge frame body 1, a plurality of corrugated boards 3 are fixed on the top of the bridge frame body 1, a circulation mechanism is arranged on the top of the bridge frame body 1, and the bridge frame body 1 1 There is a cooling mechanism at the bottom;

[0035] The circulation mechanism includes two radiating pipes 4, the radiating pipes 4 are fixedly arranged on the top of the bridge frame body 1, the radiating pipes 4 pass through the corrugated board 3 and are fixedly connected with the corrugated board 3, and between the two radiating pipes 4 A return pipe 6 is provided, the return pipe 6 penetrates through the corrugated board 3 and is fixedly connected with the corrugated board 3, and the top of the return pipe 6 and the heat dissipation pipe 4 is provided with an exhaust hole 5, and one end of the re...

Embodiment 2

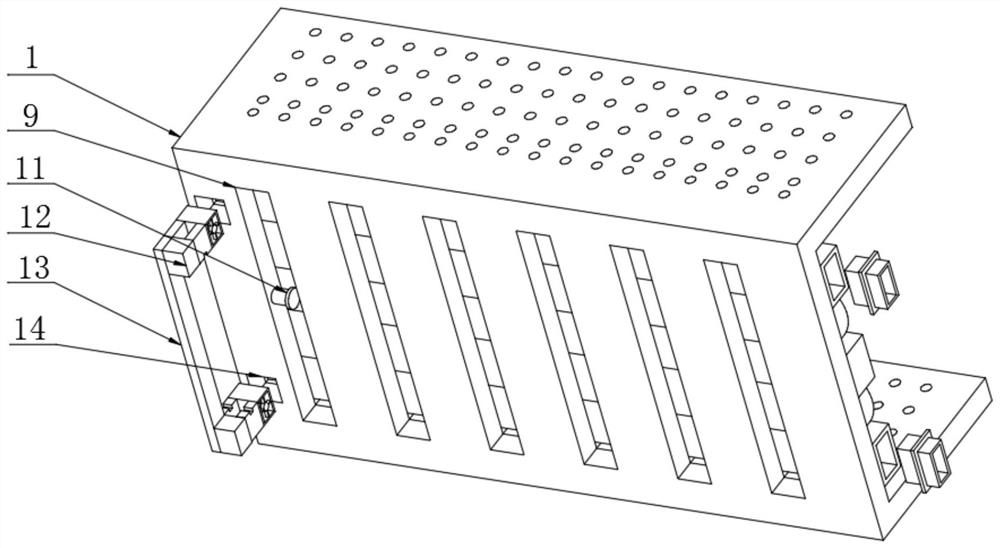

[0045] Example 2, with reference to the attached Figure 11 , The present invention provides a corrugated bridge with a wind power circulation system, the support assembly includes a support rod 35, the two ends of the support rod 35 are fixedly connected to the side walls of the casing 12 on both sides.

[0046] The use process of the present invention is as follows: when using the present invention, several bridge bodies 1 are spliced together and fixed, and the radiating pipes 4 between each bridge body 1 are connected by a connecting shell 2, and the connecting shell 2 has communication and sealing. According to the length of the erection, install the heat dissipation mechanism at an appropriate distance, insert the casing 17 from the slot 14 at the bottom of the bridge body 1, and make the casings 17 on both sides enter the heat dissipation pipes 4 on both sides, and the casing 12 The support rod 35 between them has a supporting function. After the insertion is complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com