Automobile battery liquid cooling heat dissipation device based on steam cavity heat dissipation technology

A technology for liquid cooling and heat dissipation of automobiles, applied to secondary batteries, circuits, electrical components, etc., can solve problems such as poor temperature uniformity and complex structure, and achieve compact layout, high cooling efficiency, and reduced heat transfer resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

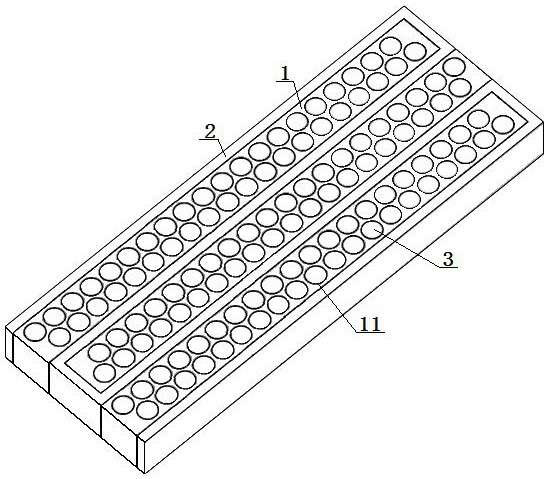

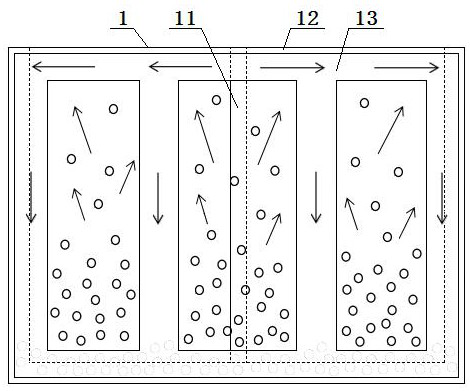

[0047] A car battery liquid cooling heat dissipation device based on steam chamber heat dissipation technology, the liquid cooling heat dissipation device includes: a heat conduction steam chamber 1, a liquid cooling channel 2 and a plurality of power batteries 3, and the liquid cooling channel 2 is curved in a reverse direction structure, a heat conduction steam chamber 1 closely attached to the bending area of the liquid cooling channel 2 is provided, and a plurality of battery installation grooves 11 are arranged on the heat conduction steam chamber 1, and a single battery battery installation groove 11 is fixed with A power battery 3; the heat conduction steam chamber 1 is a vacuum steam chamber filled with pure water and provided with a capillary core structure; the power battery 3 is fixed in the battery installation groove 11 through thermal conductive glue or graphite sheet; the liquid cooling The channel 2 includes at least two cooling horizontal pipes 21 arranged in...

Embodiment 2

[0049] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

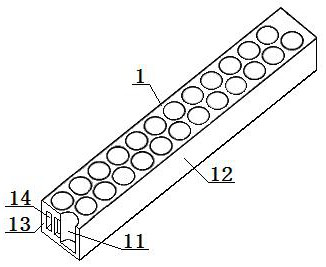

[0050] The heat conduction steam chamber 1 includes: a heat conduction shell 12, a heat conduction capillary core 13, the inner wall of the heat conduction shell 12 is provided with a heat conduction capillary core 13 connected with it as a whole, and the middle part of the heat conduction capillary core 13 is along the heat conduction steam chamber 1 At least one steam cavity 14 is opened in the direction of the central axis; one to two rows of battery installation grooves 11 are opened on the heat conduction housing 12, and the top of the battery installation grooves 11 is sealed and connected with the top plate of the heat conduction housing 12, so The groove wall of the battery installation groove 11 is a sealed structure, and the groove wall of the battery installation groove 11 is in close contact with the heat conduction capillary core 13 at the corresponding position inside the heat cond...

Embodiment 3

[0052] Embodiment 3 is basically the same as Embodiment 2, and its difference is:

[0053] The middle part of the heat-conducting capillary wick 13 is provided with three parallel steam cavities 14 along the central axis of the heat-conducting steam cavity 1 , wherein the steam cavity in the middle has a larger cross-sectional area than the rest of the steam cavities.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com