Device and method for micro-nano defect detection of terahertz materials based on multi-frequency point information fusion

A terahertz material and defect detection technology, which is applied in the field of terahertz material micro-nano defect detection devices, can solve the problems of lack of multi-band terahertz signal fusion function, inability to obtain material physical and chemical information, and poor detection accuracy of micro-nano defects. , to improve the far-field detection efficiency of evanescent signals, realize the detection and analysis of micro-nano defects, and facilitate integrated extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

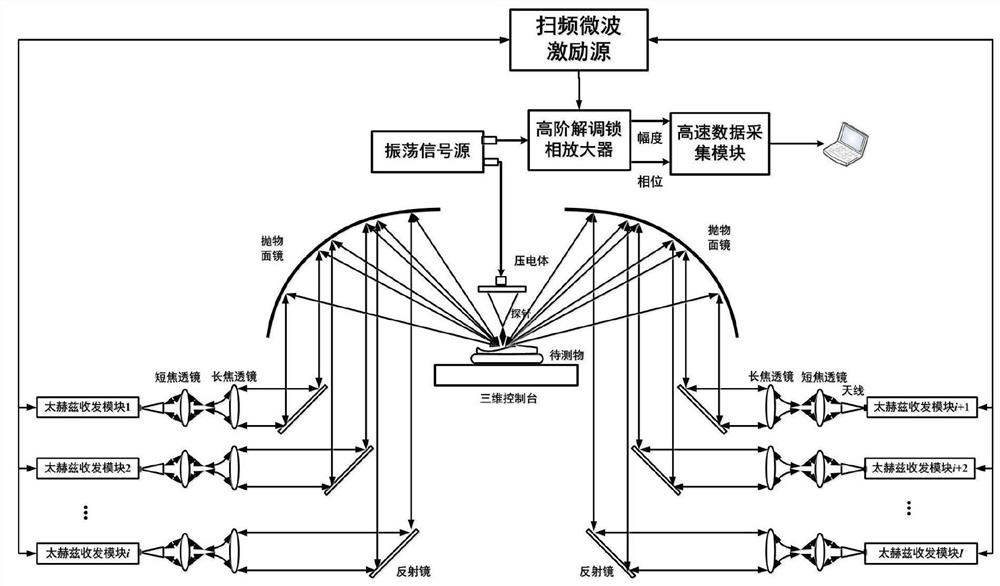

[0076] This embodiment provides a micro-nano defect detection device for terahertz materials based on multi-frequency point information fusion.

[0077] A micro-nano defect detection device for terahertz materials based on multi-frequency point information fusion, including: a microwave excitation source, a terahertz transceiver module, a mirror combination module, a nano-probe, an oscillation signal source, a lock-in amplifier and a host computer; wherein,

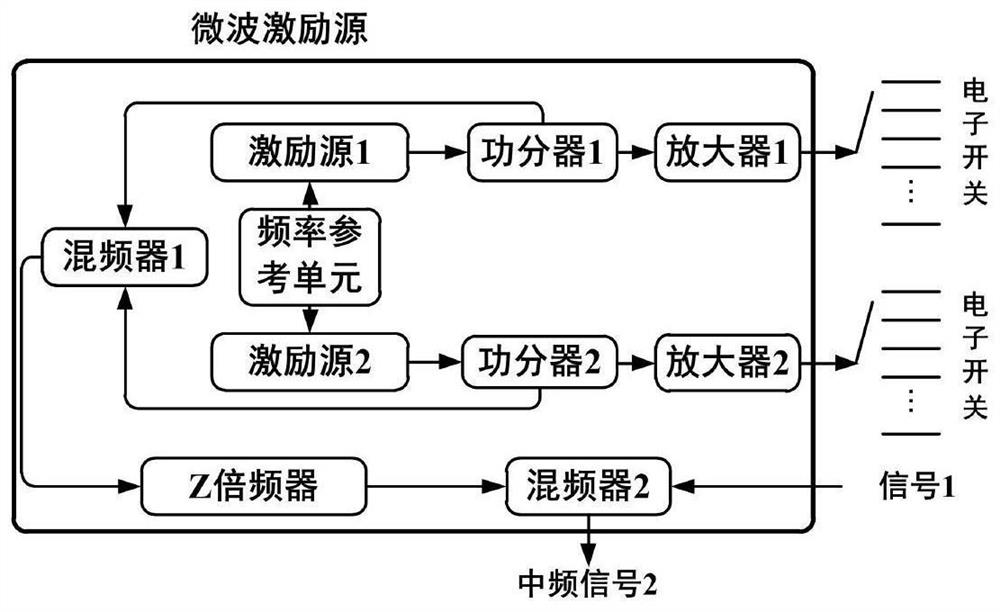

[0078] The microwave excitation source is used to generate the input signal input to the terahertz transceiver module and the frequency mixing signal input to the lock-in amplifier;

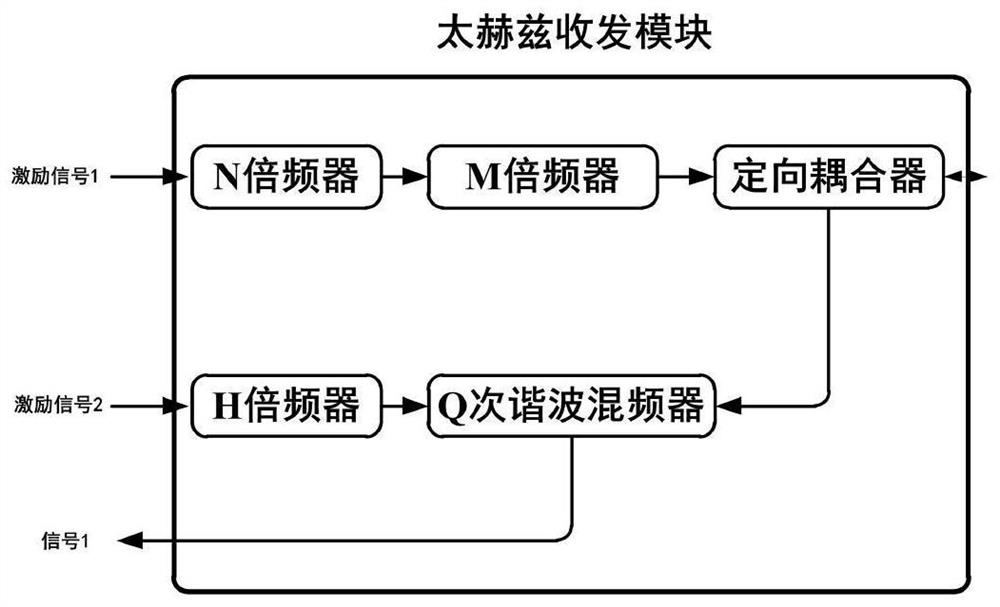

[0079] A terahertz transceiver module for continuously radiating terahertz waves and receiving locally enhanced and modulated evanescent signals by nanoprobes;

[0080] The mirror combination module is used to tightly couple the terahertz beam radiated by the terahertz transceiver module at the tip of the nanoprobe, and reflect the locally e...

Embodiment 2

[0110] This embodiment provides a method for detecting micro-nano defects in terahertz materials based on multi-frequency point information fusion.

[0111] The method for detecting micro-nano defects in terahertz materials based on multi-frequency point information fusion adopts the above-mentioned device for detecting micro-nano defects in terahertz materials based on multi-frequency point information fusion as described in Embodiment 1, including:

[0112] Control the distance between the sample to be tested and the probe, and make the three-dimensional console move in nanometers;

[0113] The terahertz transceiver module continuously radiates the terahertz wave and receives the locally enhanced and modulated evanescent signal by the nanoprobe; the amplitude and phase information of the evanescent signal at a certain position of the sample to be tested is obtained through lock-in amplification and high-order demodulation;

[0114] The three-dimensional scanning console cont...

Embodiment 3

[0154] This embodiment provides a method for detecting micro-nano defects in terahertz materials based on multi-frequency point information fusion.

[0155] The method for detecting micro-nano defects in terahertz materials based on multi-frequency point information fusion adopts the above-mentioned device for detecting micro-nano defects in terahertz materials based on multi-frequency point information fusion as described in Embodiment 1, including:

[0156] Obtain the amplitude matrix and phase matrix of the evanescent signal of the sample to be tested;

[0157] According to the amplitude matrix and phase matrix of the evanescent signal of the sample to be tested, the terahertz near-field imaging algorithm is used to obtain the terahertz near-field image of the sample to be tested at this frequency;

[0158] Obtain the terahertz near-field images of the sample to be tested at all frequencies within the swept bandwidth at specific intervals, and use an information fusion algo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com