An aoi vision test system for scratch detection of mobile phone wireless charging base

A mobile phone wireless charging and testing system technology, applied in the field of AOI visual testing system for mobile phone wireless charging base scratch detection, can solve the problems of inconvenient automatic cutting, inconvenient automatic flip detection, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

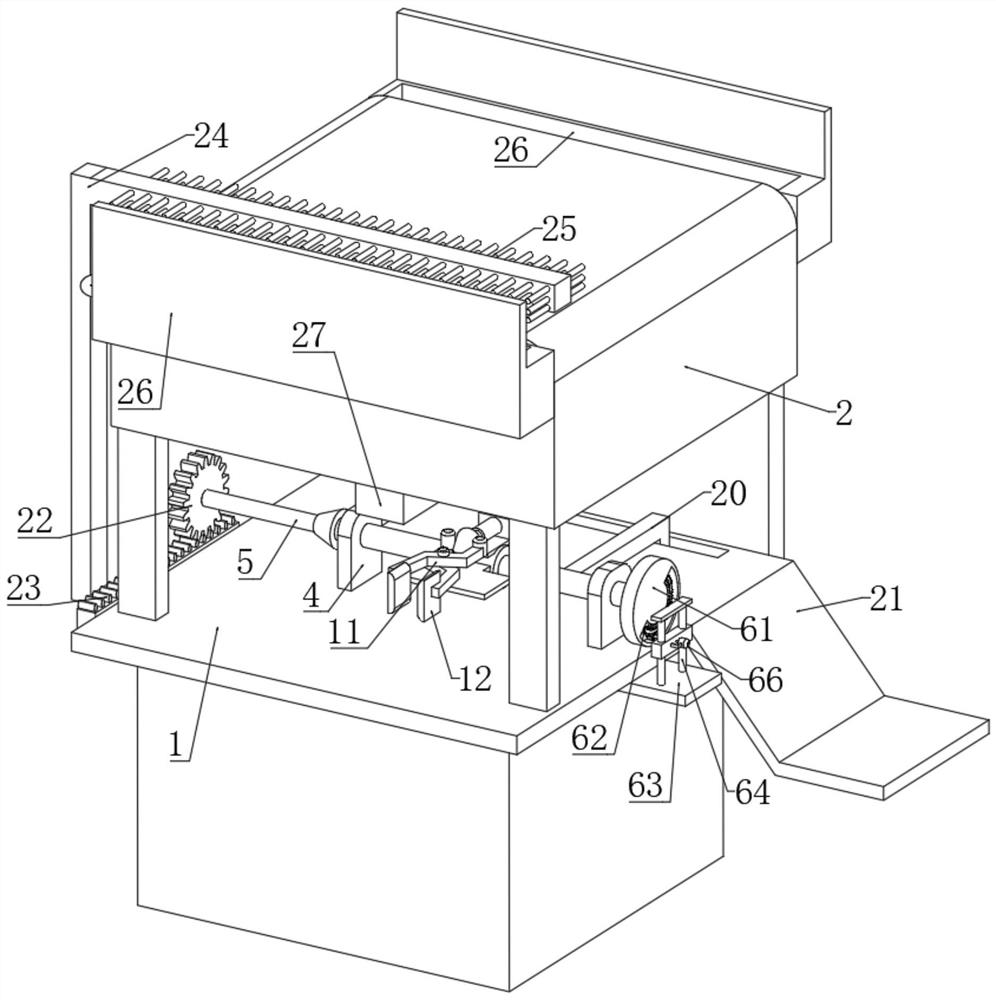

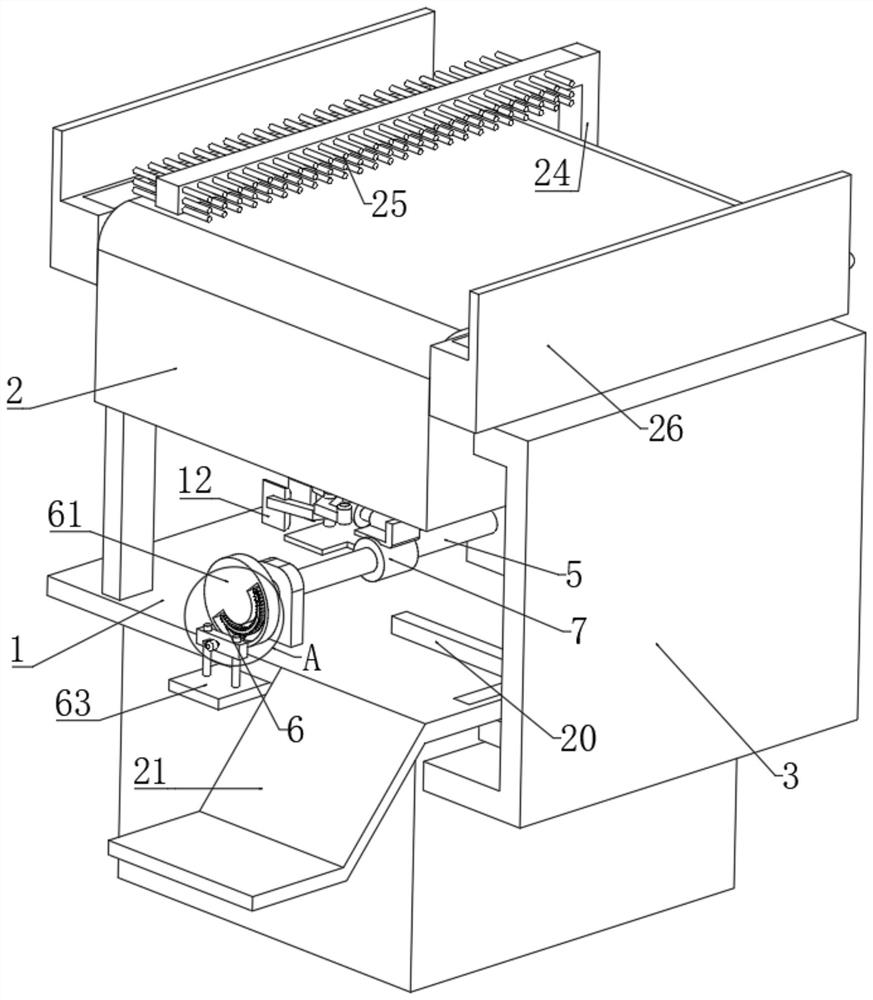

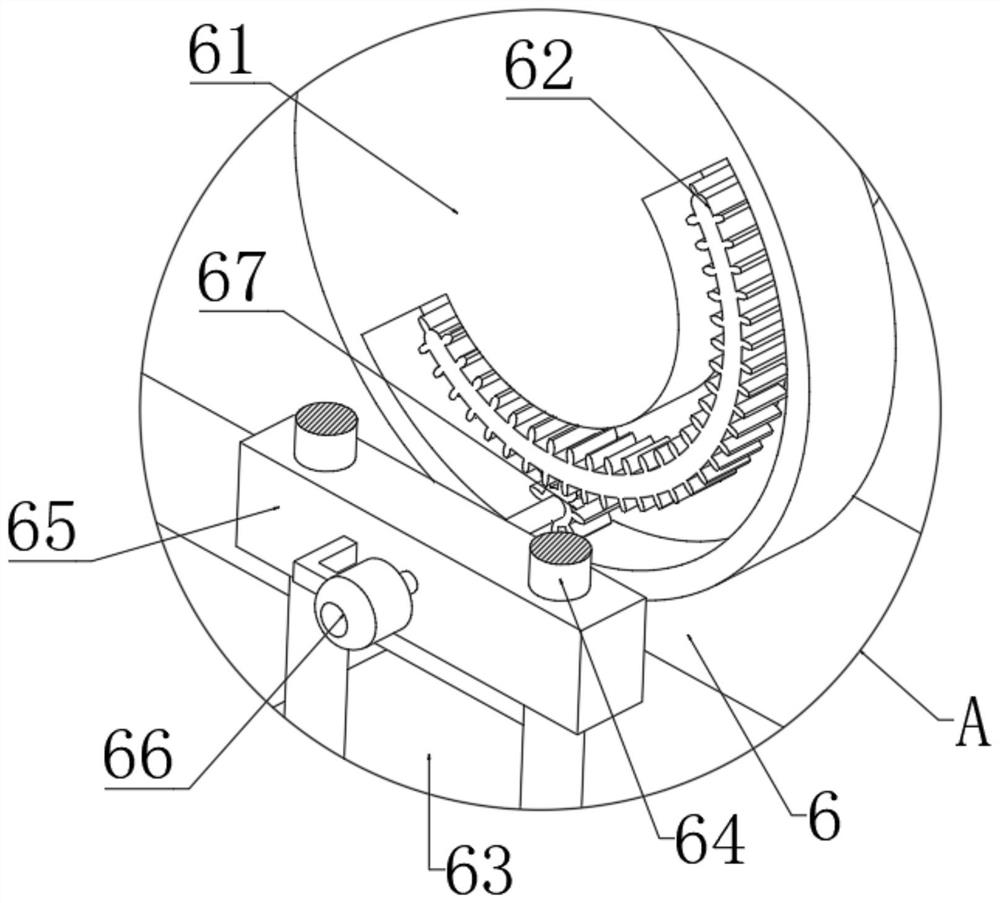

[0025]Embodiment 1: An AOI visual test system for scratch detection of mobile phone wireless charging base, including a workbench 1 and a detection device 2, a display screen 3 is installed on the rear end of the detection device 2, and the display screen 3 and the detection device 2 Electrical connection, the upper end surface of the workbench 1 is symmetrically fixedly connected with the boss 4, and the support shaft 5 is connected with the support shaft 5 through the rotation between the bosses 4, the right end of the support shaft 5 is provided with a reciprocating mechanism 6, and the outer wall of the support shaft 5 is fixed Connected with a fixed sleeve 7, the upper end surface of the fixed sleeve 7 is fixedly connected with the electric telescopic rod 8 through the mounting plate, the front end surface of the fixed sleeve 7 is fixedly connected with the support plate 10, and the upper end surface of the support plate 10 is connected with scissors through the symmetrical...

Embodiment 2

[0026] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the outer wall of the support shaft 5 is fixedly connected with the first bevel gear 14, and the upper end surface of the workbench 1 is connected with the transmission shaft 16 through the convex plate 17, and the transmission shaft 16 The front end surface is fixedly connected with the second bevel gear 15, the first bevel gear 14 is meshed with the second bevel gear 15, the right end of the transmission shaft 16 is fixedly connected with the first gear 18, and the lower end surface of the workbench 1 is slidably connected with the first gear Bar 19, the first gear 18 is meshed with the first rack 19, the upper end surface of the workbench 1 is slidably connected with a push plate 20 through the chute, and one end of the push plate 20 penetrating the chute is fixedly connected with the first rack 19, supporting The left end of the shaft 5 is fixedly connected with a second gear 22, the left s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com