Wall supporting pipe for coal seam drilling and coal seam gas extraction system using wall supporting pipe

A branch wall pipe and coal seam technology, which is applied in the field of coal bed methane drainage system, can solve the problems of inability to judge water injection, hole collapse, and inability to continue construction operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

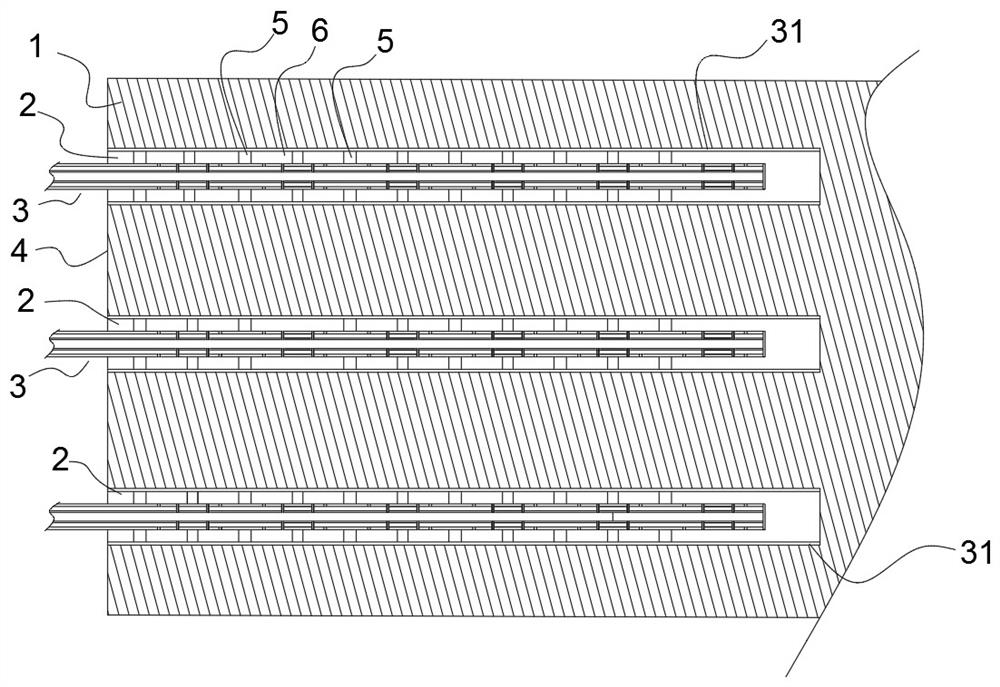

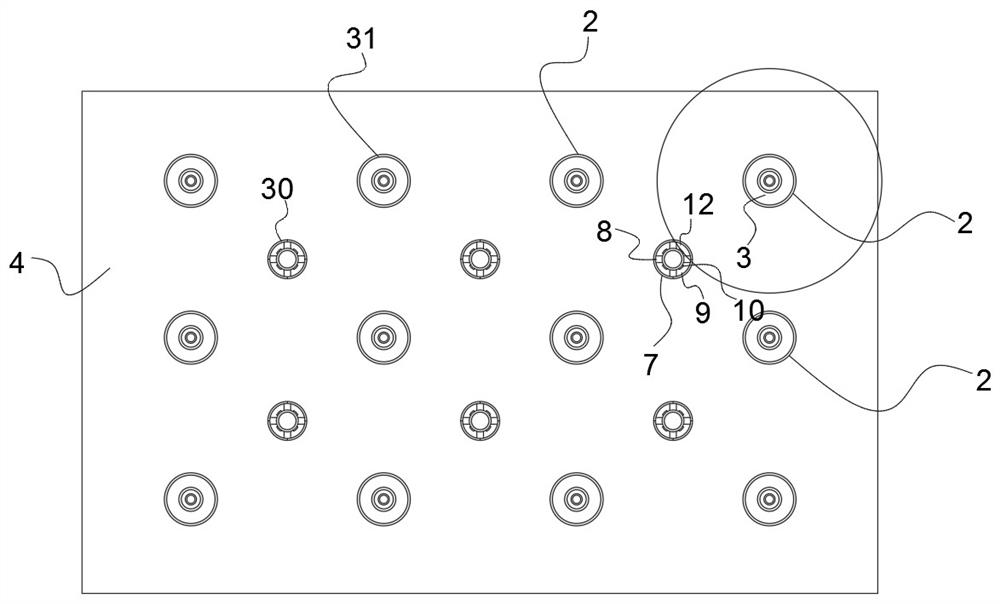

[0027] The embodiment of coalbed methane extraction system in the present invention is for example Figure 1~9 Shown:

[0028] It includes a plurality of sampling holes 7 whose axes extend along the front-to-back direction on the recovery working face 4 , and four sampling holes 2 are evenly distributed on the periphery of each sampling hole, and the drainage holes 2 and the sampling holes 7 are arranged side by side.

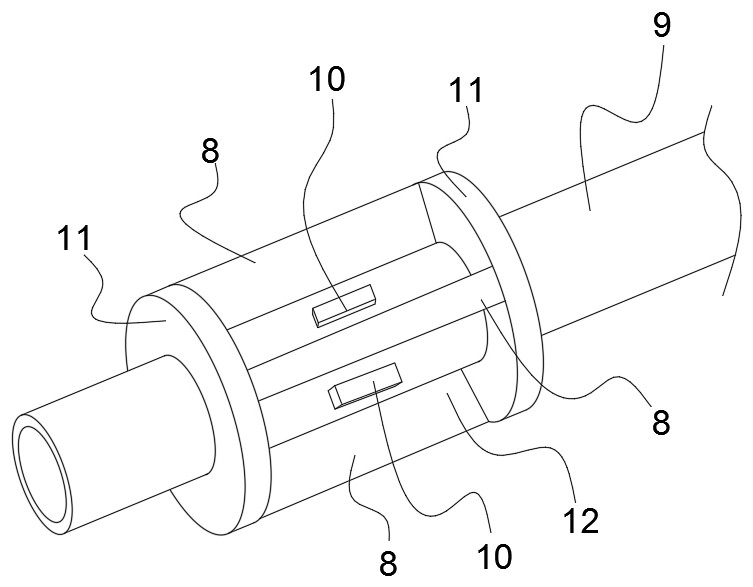

[0029] Each drainage hole 2 is provided with a drainage pipe 3, and a drainage hole branch wall pipe 31 is arranged between the drainage pipe 3 and the hole wall of the drainage hole 2. The drainage pipe 3 includes a drainage inner pipe arranged inside and outside. 21 and the extraction outer pipe 20, the extraction inner pipe 21 has an inner hole 28 for extracting coalbed methane, and a water injection channel 22 is formed between the extraction outer pipe 20 and the extraction inner pipe 21, and the upper edge of the extraction outer pipe A plurality of extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com