Design method of sinking headframe for vertical shaft expanding excavation

A design method and well-sinking technology, which can be used in vertical shaft equipment, drilling equipment, mining equipment, etc., can solve problems such as non-reuse, inability to perform overall translation operations, and distortion of tubular derricks, so as to reduce the floor space and increase the daily The effect of maintenance, inspection and repair work and reducing the space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

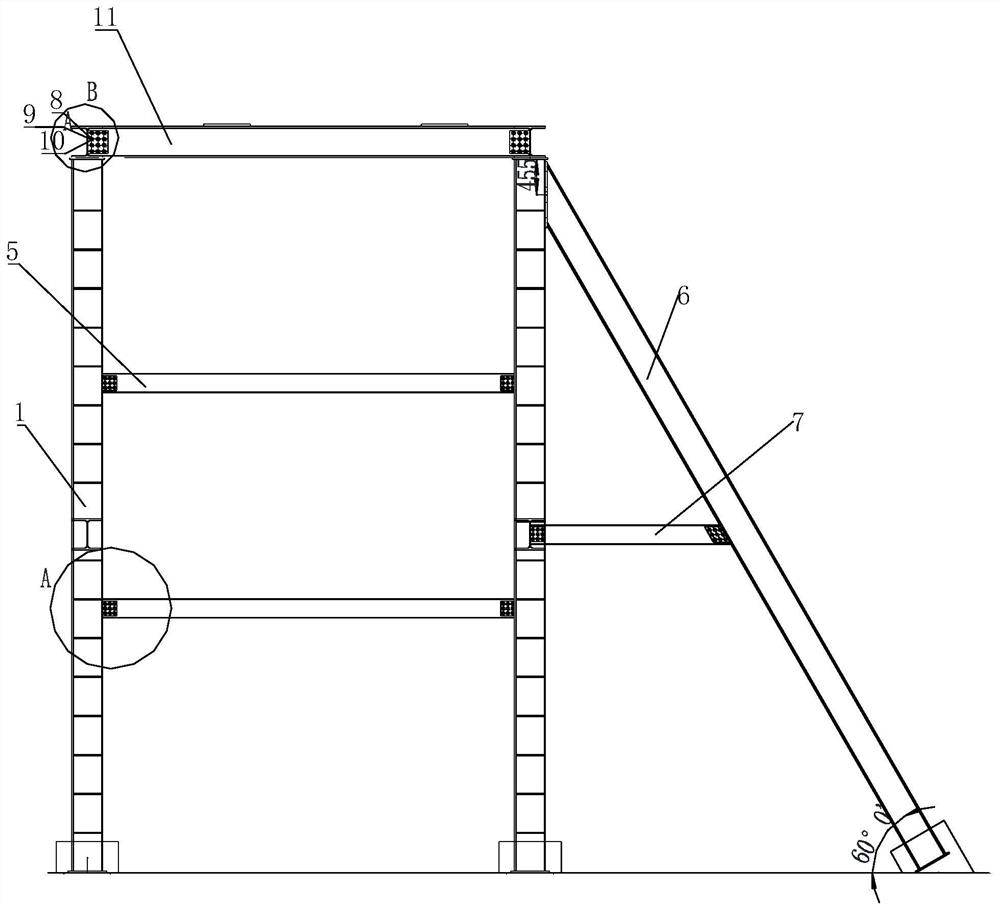

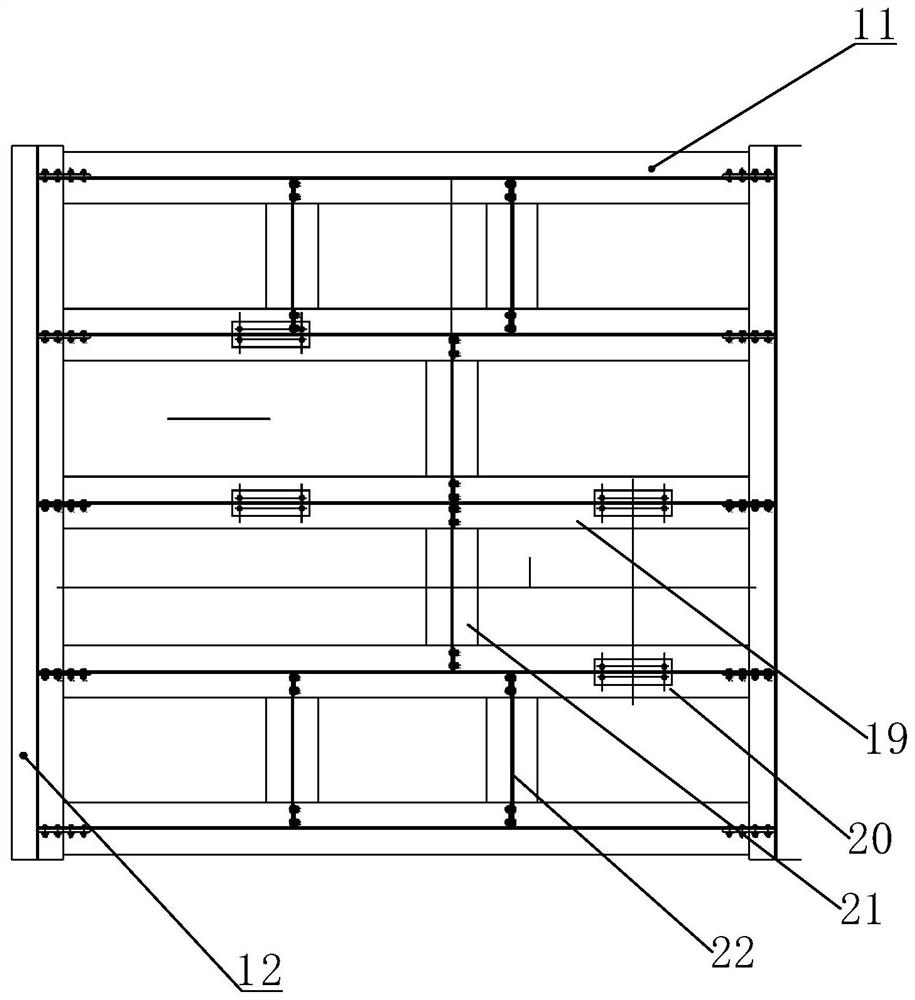

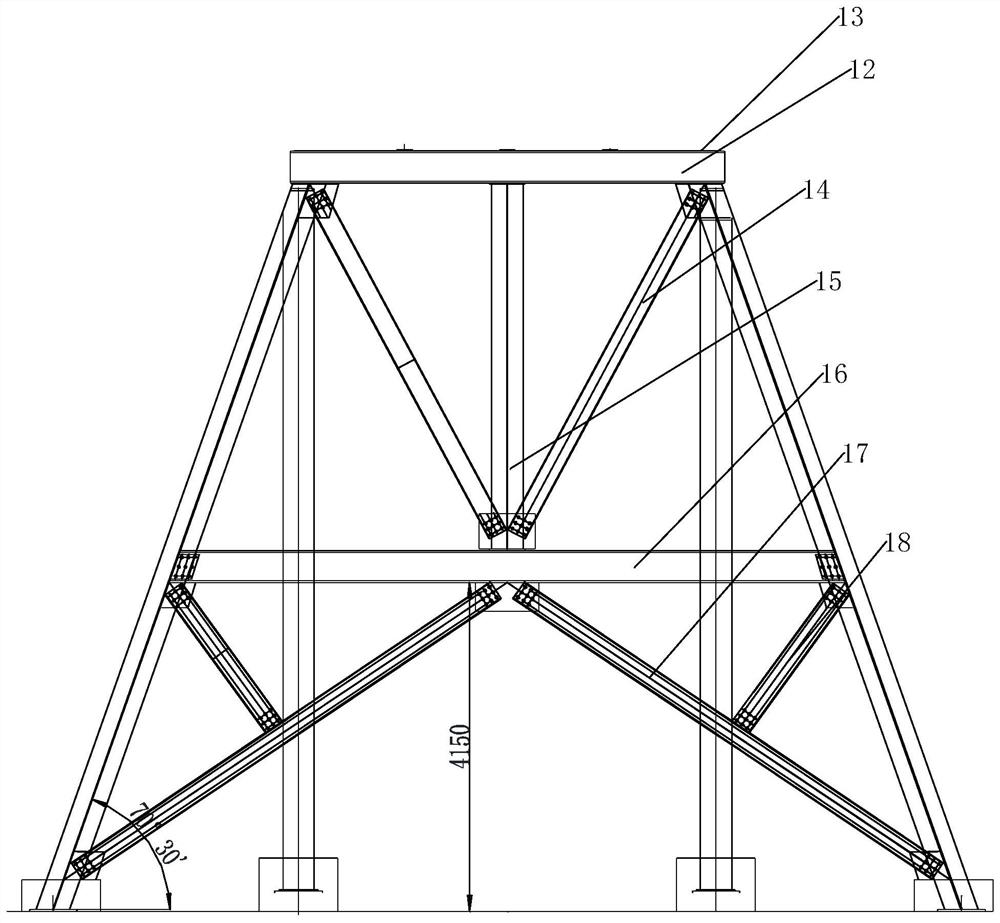

[0130] The new type of vertical shaft expansion and sinking derrick is designed to meet the type of shaft construction operations of vertical shaft brushing and lower horizontal gangue. Supported by integral steel frame. The force is uniform and reasonable, and the plane and three-dimensional space are saved.

[0131] 1. Construction background

[0132] The Yili River IV Hydropower Station is located in the downstream Jinsha River Baihetan Hydropower Station reservoir area. The hydropower station hub consists of the first hub building and the water diversion power generation system building. After the Baihetan Hydropower Station stores water to generate electricity, the backwater of the reservoir will submerge the tail water system, underground powerhouse and part of the water diversion tunnel of the Yili River IV Hydropower Station. recovery.

[0133] The ground outlet field is located in the gentle slope of Dapingzi on the east side of the underground factory building, cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com