Thin-wall open steel box-prestressed reinforced concrete combined cover beam and construction method

A technology of reinforced concrete and prestressed steel bars, applied in bridges, bridge materials, bridge construction, etc., can solve the problems of heavy lifting weight, difficult transportation and lifting of prefabricated cover beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in combination with specific embodiments.

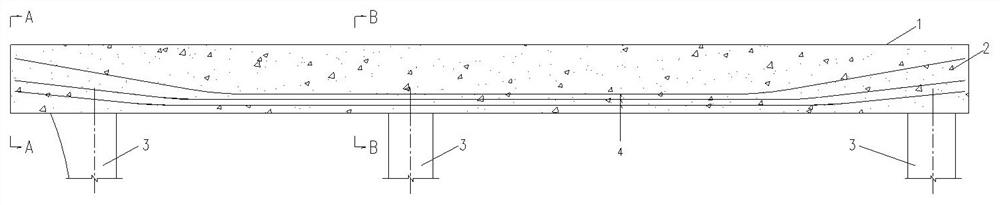

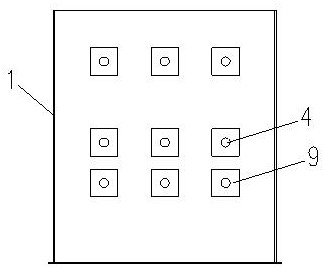

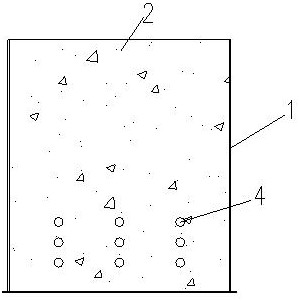

[0040] The invention relates to a thin-wall open steel box-prestressed reinforced concrete composite cover beam, the composite cover beam 14 includes a thin-wall open steel box 1 and at least one pier column 3; the thin-wall open steel box 1 is provided with internal steel bars The cage 5 is poured with concrete; the top of the pier column 3 is provided with a pre-embedded wedge-shaped steel block 10 at the top of the pier, and the bottom of the thin-walled open steel box 1 corresponding to the position of the pier column 3 is welded and fixed with a reinforced steel plate 12 at the bottom of the cover beam. The block 10 is welded and fixed to the reinforced steel plate 12 at the bottom of the cover beam to realize the connection between the pier column 3 and the thin-walled open steel box 1 .

[0041] The thin-walled open steel box 1 is a hollow steel box without a top c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com