Dry-mixed interface mortar

A technology of interface mortar and dry mixing, which is applied in the field of building materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

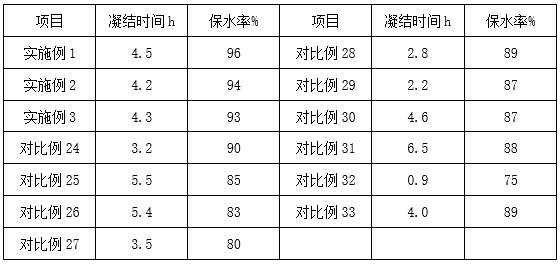

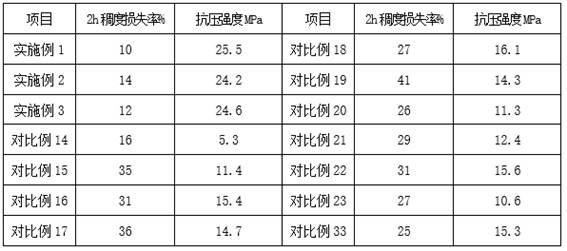

Examples

Embodiment 1

[0040] A dry-mixed interface mortar, wherein the dry-mixed interface mortar raw materials include P.O42.5 cement: 400-450 parts, machine-made sand: 550 parts, cellulose ether: 3-4 parts, modified latex powder: 10-20 parts , 5-7.5 parts of coagulant;

[0041] The specific preparation methods include:

[0042] 1) Preparation of machine-made sand:

[0043] 1) Put the flakes into a jaw crusher for crushing, and crush them into particles with a particle size of 3-4cm. Put the particles into a high-energy ball mill for ball milling, and crush them into particles that can pass through a 300-mesh sieve;

[0044] 2) Put hectorite into ethanol solution, soak for 12 hours, wash it several times, dry it, take it out and put it into a jaw crusher for crushing, and crush it into particles with a particle size of 3-4cm, put the particles into high-energy In the ball mill, carry out ball milling and pulverization until it is broken into particles that can pass through a 300-mesh sieve;

[00...

Embodiment 2

[0066] A dry-mixed interface mortar, wherein the dry-mixed interface mortar raw materials include P.O42.5 cement: 400-450 parts, machine-made sand: 550 parts, cellulose ether: 3-4 parts, modified latex powder: 10-20 parts , 5-7.5 parts of coagulant;

[0067] The specific preparation methods include:

[0068] 1) Preparation of machine-made sand:

[0069] 1) Put the flakes into a jaw crusher for crushing, and crush them into particles with a particle size of 3-4cm. Put the particles into a high-energy ball mill for ball milling, and crush them into particles that can pass through a 300-mesh sieve;

[0070] 2) Put hectorite into ethanol solution, soak for 12 hours, wash it several times, dry it, take it out and put it into a jaw crusher for crushing, and crush it into particles with a particle size of 3-4cm, put the particles into high-energy In the ball mill, carry out ball milling and pulverization until it is broken into particles that can pass through a 300-mesh sieve;

[...

Embodiment 3

[0092] A dry-mixed interface mortar, wherein the dry-mixed interface mortar raw materials include P.O42.5 cement: 400-450 parts, machine-made sand: 550 parts, cellulose ether: 3-4 parts, modified latex powder: 10-20 parts , 5-7.5 parts of coagulant;

[0093] The specific preparation methods include:

[0094] 1) Preparation of machine-made sand:

[0095]1) Put the flakes into a jaw crusher for crushing, and crush them into particles with a particle size of 3-4cm. Put the particles into a high-energy ball mill for ball milling, and crush them into particles that can pass through a 300-mesh sieve;

[0096] 2) Put hectorite into ethanol solution, soak for 12 hours, wash it several times, dry it, take it out and put it into a jaw crusher for crushing, and crush it into particles with a particle size of 3-4cm, put the particles into high-energy In the ball mill, carry out ball milling and pulverization until it is broken into particles that can pass through a 300-mesh sieve;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com