Cutting position precise adjustment structure for coil film packaging

A precise adjustment, film packaging technology, applied in packaging, packaging machines, transportation and packaging, etc., can solve problems such as coil damage, achieve a strong sense of damping, reduce secondary inertial friction, and reduce the effect of advancing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

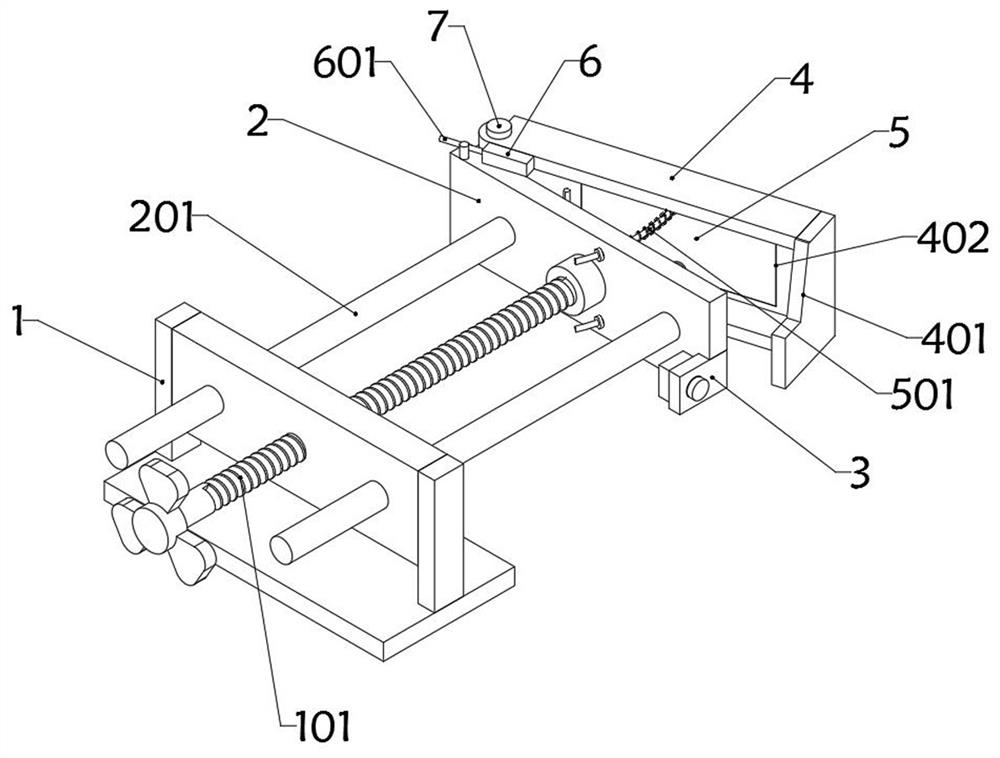

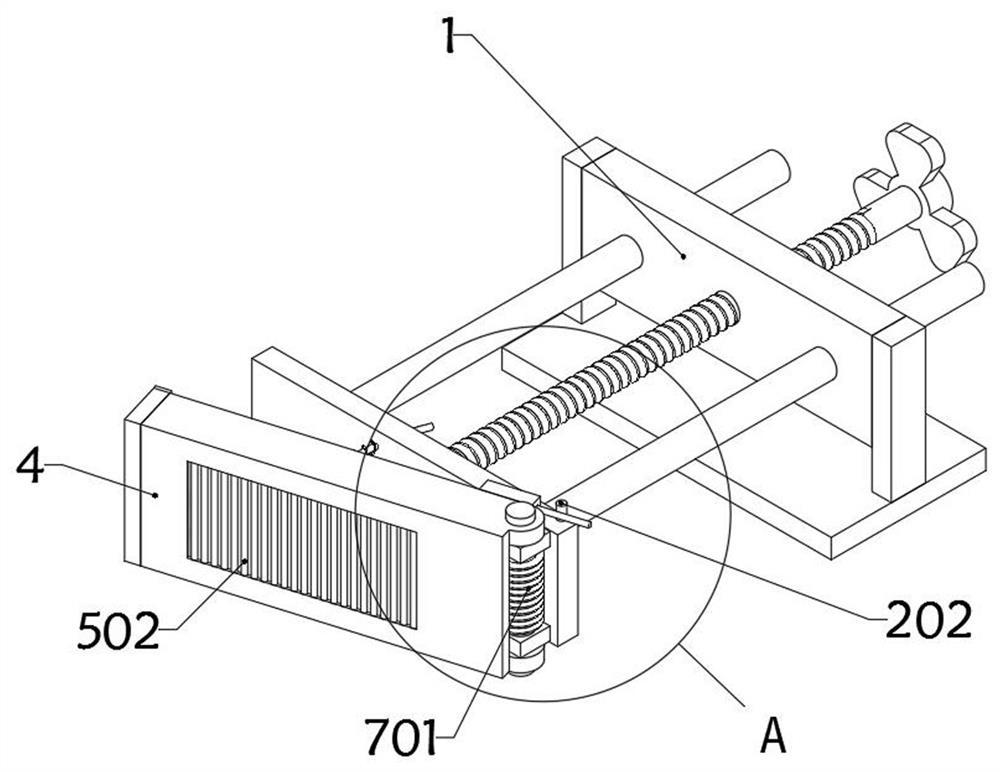

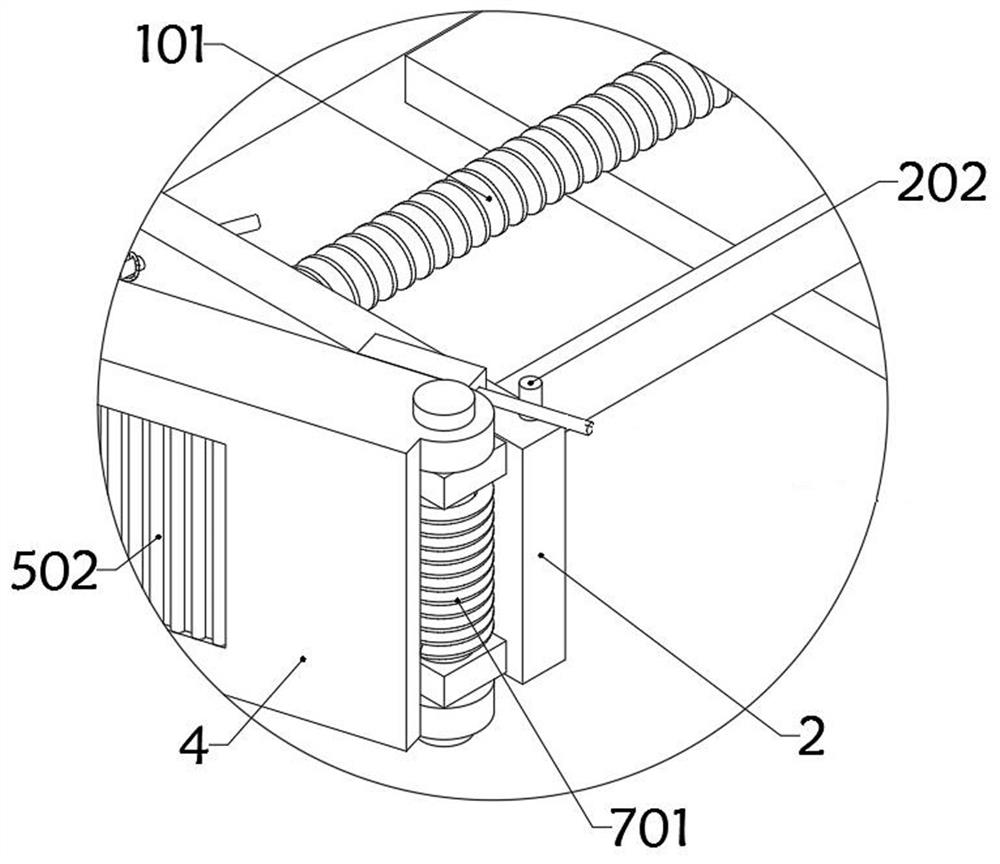

[0032] as attached figure 1 to attach Figure 8 Shown:

[0033] The invention provides a precise adjustment structure for the cutting position of coiled material film packaging, which includes an adjustment seat 1 and a stainless steel baffle 4; a thick plate 2 is installed vertically and vertically on the adjustment seat 1; Switch 3; a set of rotating mechanism is installed on the left side of the thick plate 2, the rotating mechanism includes a rotating shaft 7, and the rotating shaft 7 is socketed with the upper and lower ends of the thick plate 2; On the rotating shaft 7, an axle sleeve is installed on the stainless steel baffle 4 at the upper and lower ends of the rotating shaft 7;

[0034] Wherein, the middle part of the adjustment seat 1 is screwed with an adjusting bolt 101 for longitudinal and vertical rotation, and the rear end of the adjusting bolt 101 is screwed with the middle part of the front side wall of the thick plate 2, and the position of the thick plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com