Non-fuel air conditioner heating system for crane and method thereof

A technology of cranes and thermal systems, applied in air handling equipment, heating/cooling equipment, load suspension components, etc., can solve the problems of energy consumption, resource waste, and insufficient utilization, and achieve the effect of environmental protection and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

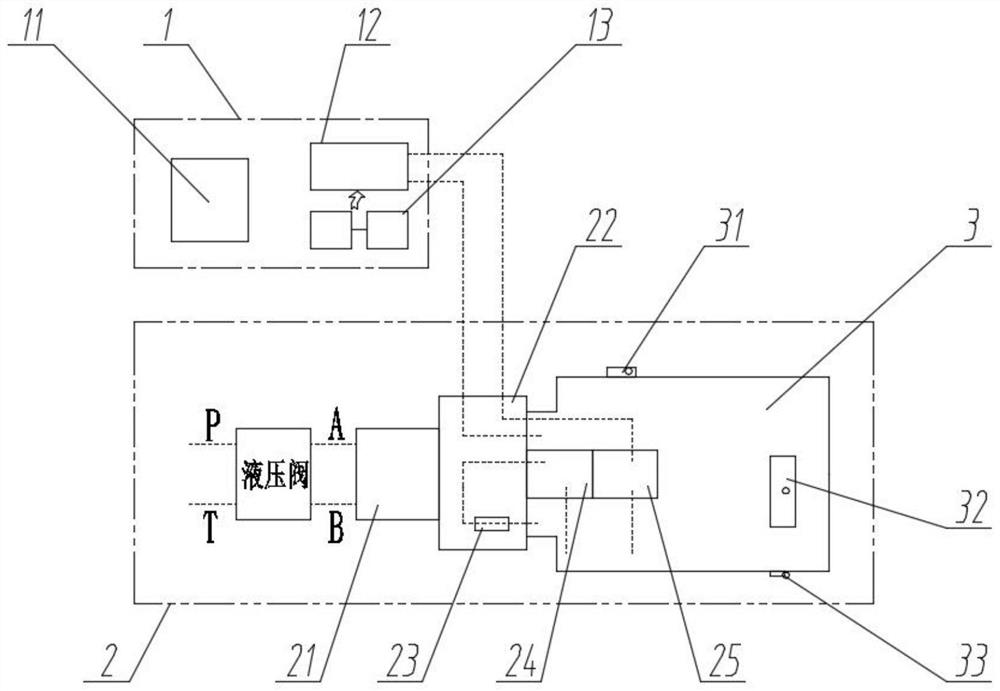

[0024] Such as figure 1 As shown, the non-fuel air-conditioning and heating system for a crane includes an outdoor unit assembly 2;

[0025] The outdoor unit assembly 2 includes a hydraulic valve, a hydraulic motor 21, a gear pump group and an oil tank 3;

[0026] The hydraulic valve inputs the hydraulic oil into the hydraulic motor 21, and the output end of the hydraulic motor 21 is connected to the gear pump set in the oil tank 3, and the gear pump set heats the heat transfer oil in the oil tank 3, and passes through the second oil outlet Transfer the heat transfer oil to the heater core 12 in the indoor unit assembly 1, so that the temperature of the heater core 12 rises, and the heat transfer oil returns to the oil tank from the second oil return circuit connected to the heater core 12 within 3;

[0027] The blower 13 blows air to the warm air core 12 to transfer the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com