Hub and barrel-shaped workpiece edge cutting equipment and processing method

A technology for workpiece edge and cutting equipment, applied in welding/cutting auxiliary equipment, metal processing equipment, welding equipment, etc. land area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

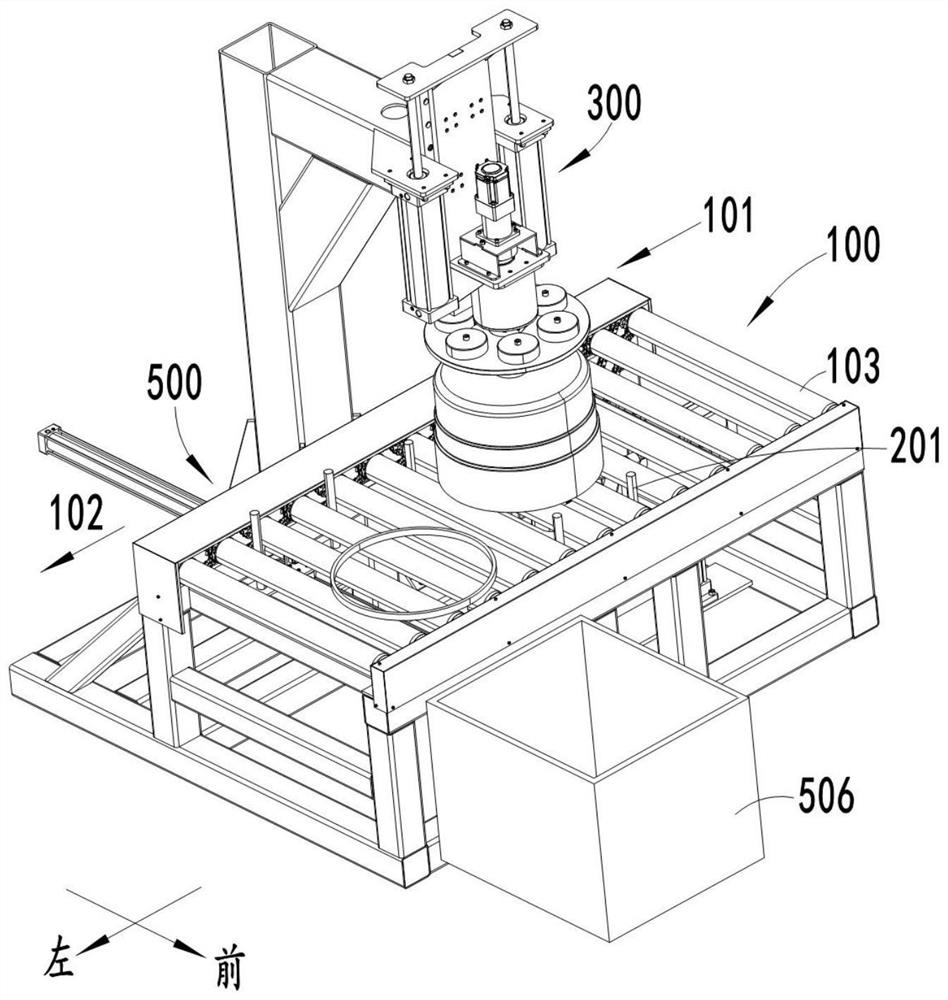

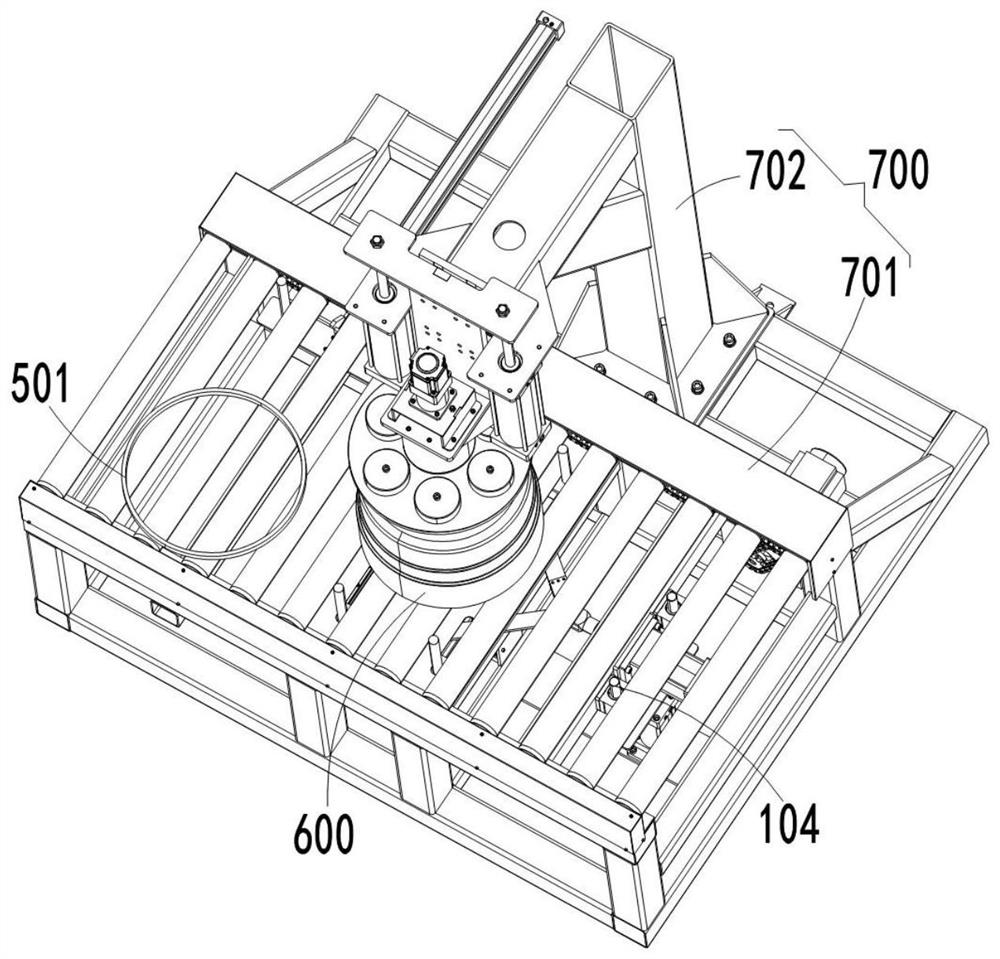

[0044] Such as Figure 1-Figure 9 As shown, a wheel hub and barrel-shaped workpiece edge cutting equipment includes a control unit and a delivery unit 100, a positioning unit 200, a clamping rotation unit 300 and a cutting unit 400 respectively connected to the control unit; the positioning unit 200 has a closed state and an open state. State, when the positioning unit 200 is in the closed state, the central axis of clamping the workpiece 600 to the workpiece 600 is coaxial with the rotation center of the clamping rotation unit 300, and when the positioning unit 200 is in the open state, a moving space 208 is formed in the positioning unit 200 The control unit is configured to control the cutting unit 400 to rise to the cutting position through the moving space 208 and perform cutting work when the positioning unit 200 is switched to the open state. The above-mentioned control unit can be PLC or industrial computer, etc., including electrical control, pneumatic control, contro...

Embodiment 2

[0055] The present invention also provides a method for processing the edge of the wheel hub and the barrel-shaped workpiece. The method for processing the edge of the wheel hub and the barrel-shaped workpiece includes the following steps:

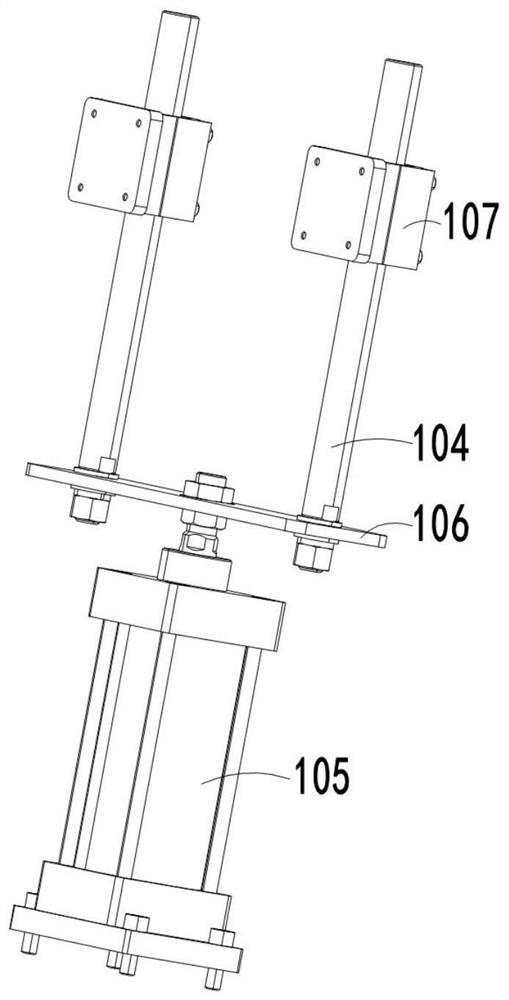

[0056] S1: the conveying unit 100 runs, the workpiece 600 to be processed is placed on the conveying unit 100, and the workpiece 600 is conveyed by the workpiece transfer side 101; the second driving device 105 drives the intercepting shaft 104 to rise and intercept the workpiece 600, and the current workpiece 600 is processed After the process is completed, the second driving device 105 drives the interception shaft 104 to drop to the initial position; the conveying unit 100 drives the workpiece 600 for a certain distance to the bottom of the clamping and rotating unit 300, and the conveying unit 100 stops;

[0057] S2: The third driving device 202 drives the positioning shaft 201 to move toward each other in the front and rear direction, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com