Bottled liquid detection system and method

A technology for bottled liquids and detection systems, applied in sorting and other directions, can solve problems such as poor repeatability, poor working environment, and strong subjectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

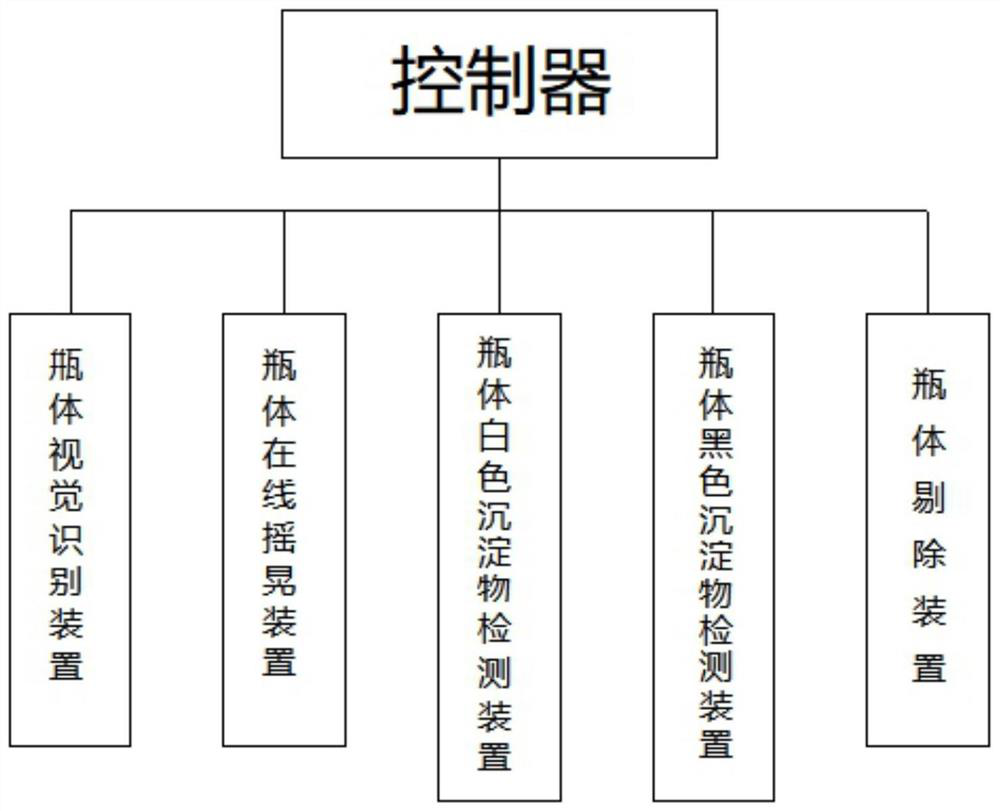

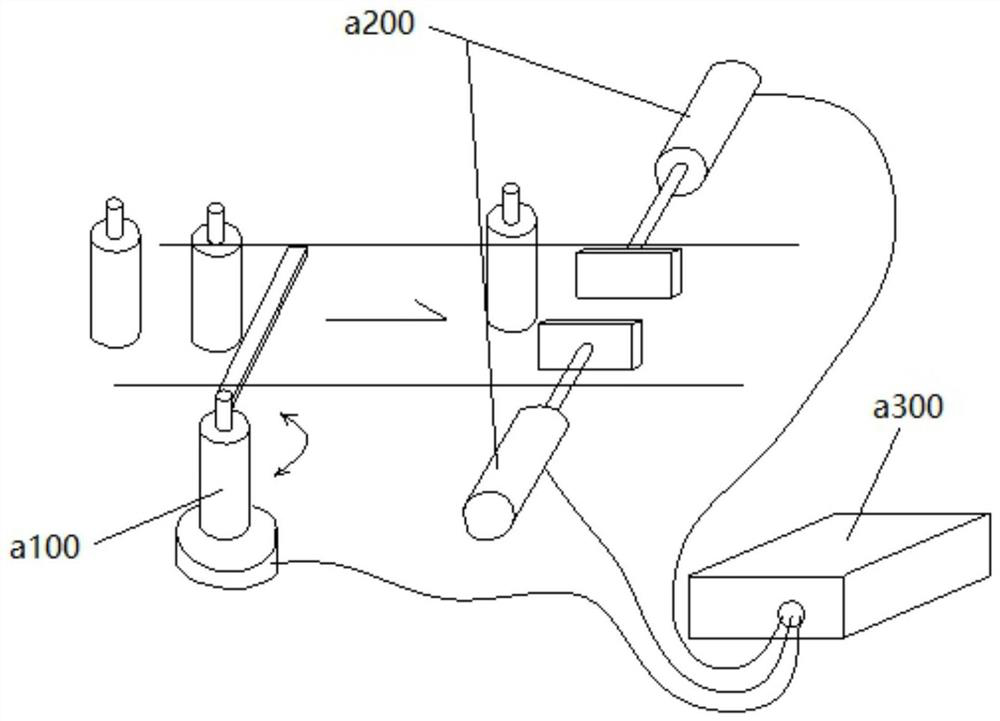

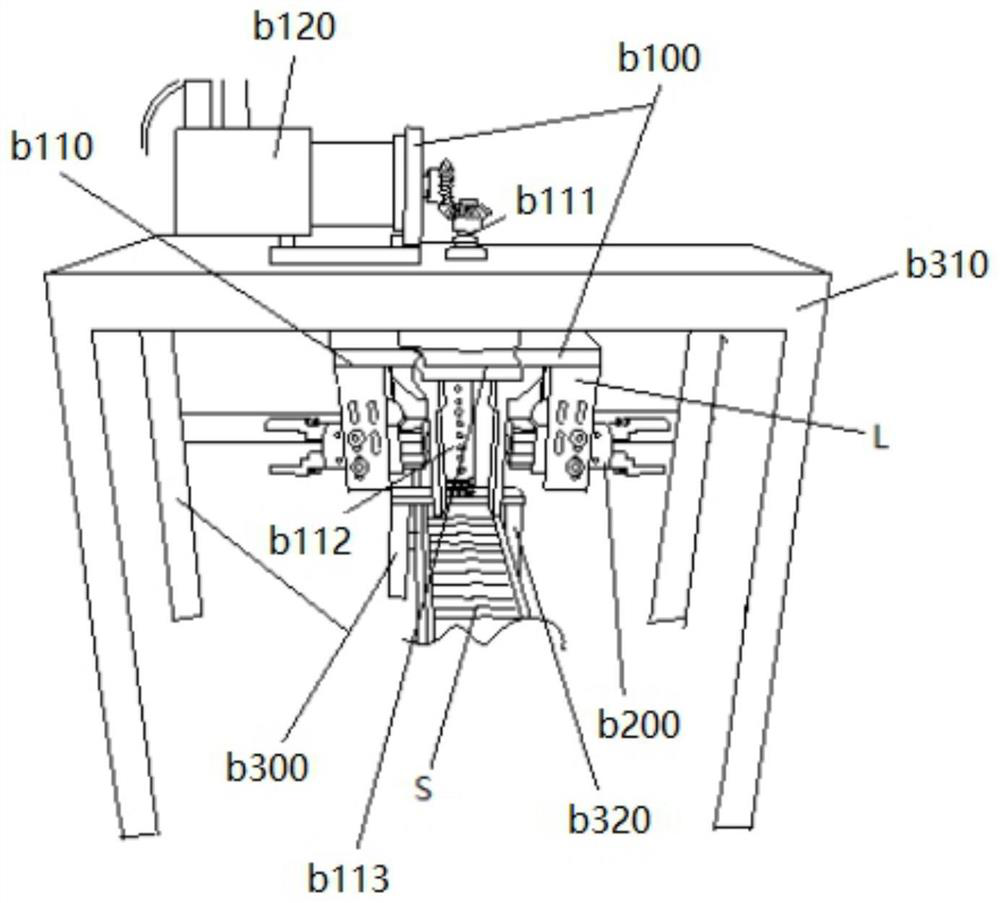

[0046] like figure 1 As shown, the present invention provides a bottled liquid detection system, which includes: a bottle body visual recognition device 200, a bottle body online shaking device 300, a bottle body visual identification device 200, a bottle body online shaking device 300, and a bottle body visual identification device 200, which are arranged in sequence according to the one-way material transport direction of the conveyor belt and are respectively electrically connected to the controller 100. White sediment detection device 400, bottle black sediment detection device 500 and bottle body rejection device 600; the bottle body visual recognition device 200 is used to identify the shape of the bottle body; the bottle body online shaking device 300 is based on the identified The shape of the bottle is selected to be equipped with a suitable handle, and is used to grab and shake the bottle; the bottle white sediment detection device 400 is used to detect whether there ...

Embodiment 2

[0057] This embodiment further provides a bottled liquid detection method on the basis of Embodiment 1, said method comprising the following steps:

[0058] Step 1: The bottle body visual recognition device recognizes the shape of the bottle body, and visually displays the number of the handle corresponding to the shape of the bottle body through the controller;

[0059] Step 2: According to the displayed number of the gripper, install the corresponding gripper for the online shaking device of the bottle;

[0060] Step 3: Start the production line, and the bottle body on-line shaking device shakes the bottles placed on the production line in sequence;

[0061] Step 4: The device for detecting white sediment in the bottle detects whether there is white sediment in the shaken bottle, and feeds back the trigger time when the white sediment is detected to the controller;

[0062] Step 5: the black sediment detection device in the bottle detects whether there is black sediment in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com