Metal oxide and halide perovskite quantum dot heterojunction visible-light-driven photocatalyst as well as preparation method and application thereof

A halide perovskite and oxide technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve problems such as limiting the use of visible light, achieve good visible light catalytic performance, mild reaction conditions, improve The effect of removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

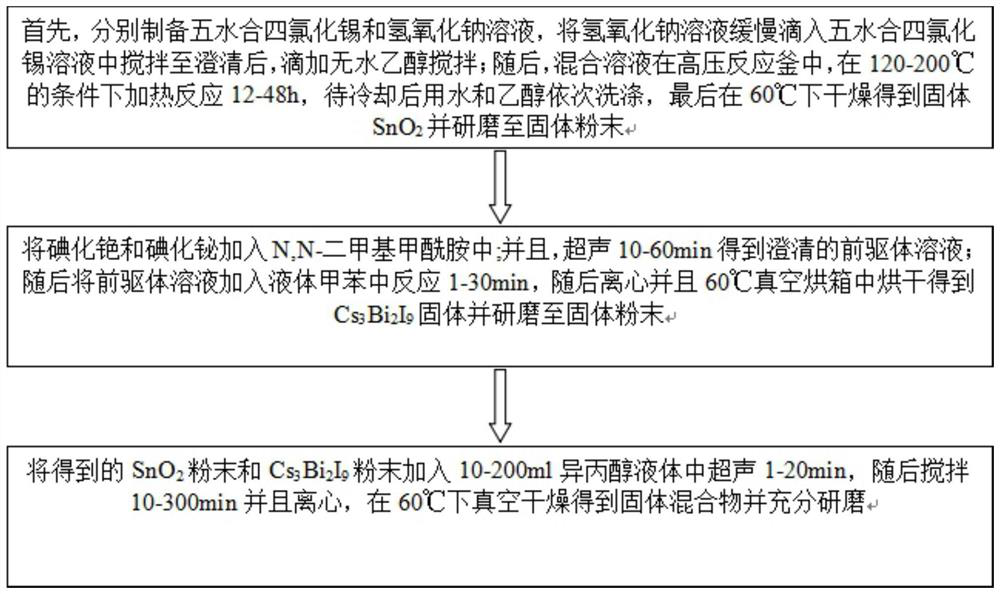

[0034] Please refer to the attached figure 1 , the SnO provided by the embodiment of the present invention 2 / Cs 3 Bi 2 I 9 The preparation method of the heterojunction visible light catalyst comprises the following steps:

[0035] Step1: Prepare the tin tetrachloride pentahydrate solution and the sodium hydroxide solution respectively, slowly drop the sodium hydroxide solution into the tin tetrachloride pentahydrate solution and stir until clarification, then add absolute ethanol dropwise and stir; subsequently, the mixed solution is In a high-pressure reactor, heat the reaction at 120-200°C for 12-48h, wash with water and ethanol in sequence after cooling, and finally dry at 60°C to obtain solid SnO 2 and ground to a solid powder;

[0036] Step2: Add cesium iodide and bismuth iodide to N,N-dimethylformamide; and at room temperature, ultrasonic power is 80KHZ, ultrasonic 10-60min to obtain a clear precursor solution; then add React in liquid toluene for 1-30min, then ce...

Embodiment 1

[0040] Pure phase SnO 2 Preparation: First, prepare 25ml solutions of tin tetrachloride pentahydrate and sodium hydroxide respectively, wherein the concentration of tin tetrachloride pentahydrate is 0.2 mmol / ml, the concentration of sodium hydroxide is 1 mmol / ml, and the concentration of tin tetrachloride pentahydrate is 1 mmol / ml. , sodium hydroxide, and dehydrated ethanol are 5mmol: 25mmol: 429mmol, the sodium hydroxide solution is slowly dripped into the tin tetrachloride pentahydrate solution and stirred until clarified, then added dropwise with dehydrated ethanol and stirred; subsequently, The mixed solution was heated and reacted at 180°C for 24 hours in a high-pressure reactor, washed with water and ethanol in sequence after cooling, and finally dried at 60°C to obtain solid SnO 2 and ground to a solid powder to obtain SnO 2 powder.

Embodiment 2

[0042] Pure phase Cs 3 Bi 2 I 9 Preparation: Add 0.9mmol cesium iodide and 0.6mmol bismuth iodide to 500ml of N,N-dimethylformamide; and at room temperature, ultrasonic power is 80KHZ, ultrasonic 30min to obtain a clear precursor solution; Then the precursor solution was added to liquid toluene to react for 5 min, then centrifuged and dried in a vacuum oven at 60 °C to obtain Cs 3 Bi 2 I 9 solid and ground to a solid powder to give Cs 3 Bi 2 I 9 powder;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com