Seawater environment simulation device for normal-temperature uniaxial creep test and installation method

An environmental simulation device and creep test technology, applied in the field of simulation test devices, can solve the problems of poor adaptability, lack of test devices and regulations, etc., and achieve the effect of compact structure, good test compatibility and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

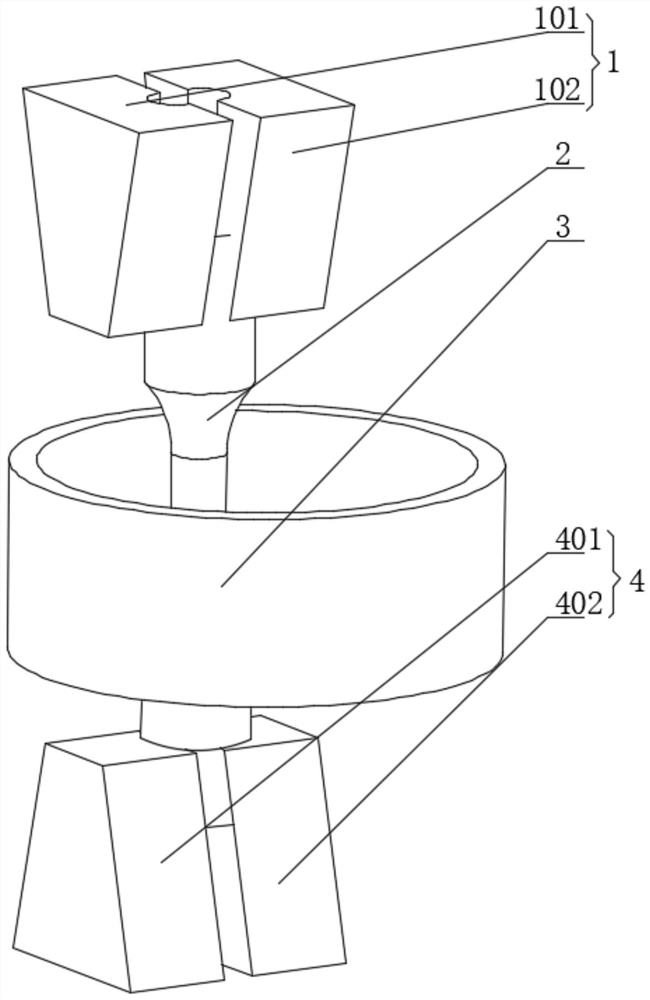

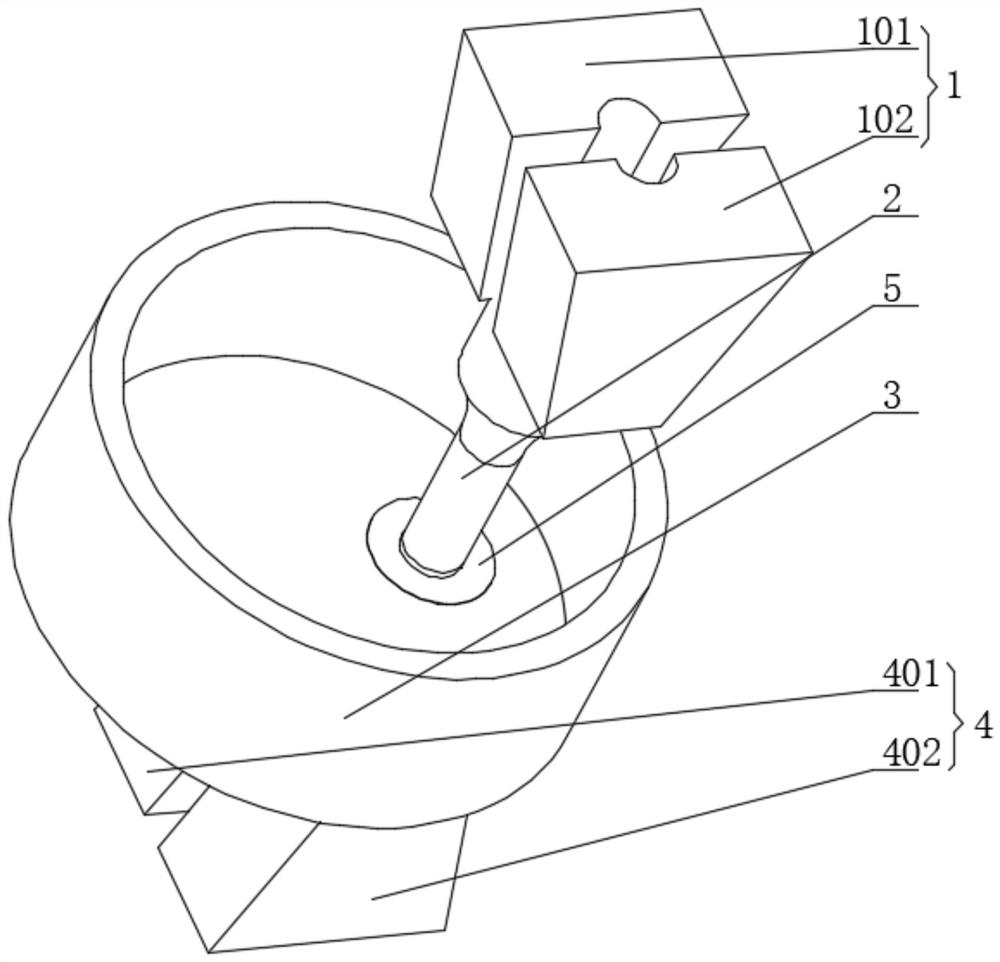

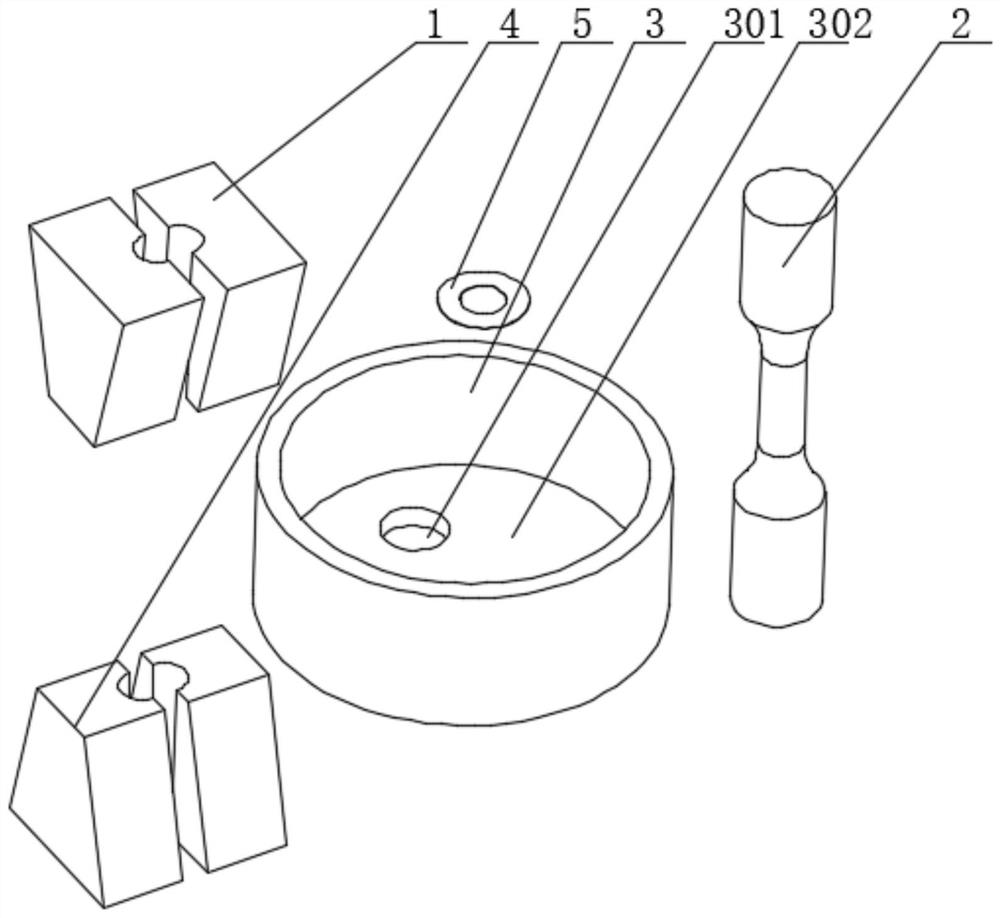

[0045] like Figure 1-Figure 5 As shown, a seawater environment simulation device and installation method for normal temperature uniaxial creep test, including a medium box 3, the medium box 3 is a cylindrical structure with an open top, the bottom of the medium box 3 is a chassis 302, the chassis There is a round hole 301 on the 302, and the round hole 301 passes through the test piece 2, and the joint between the test piece 2 and the round hole 301 is installed with a sealing glue 5, and the top of the test piece 2 is connected to the chuck 1 on the testing machine, and the bottom of the test piece 2 Connect the lower chuck 4 of the testing machine; put artificial seawater in the medium box 3 .

[0046] The center of the circular hole 301 deviates from the center of the chassis 302 .

[0047] The gauge length section of the test piece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com