Steel liquid solidification simulator in continuous casting crystallizer

A continuous casting mold and solidification simulation technology, applied in the field of iron and steel continuous casting, can solve the problems of huge equipment investment, single research, single and other problems, and achieve the effects of improving surface quality, low test cost and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

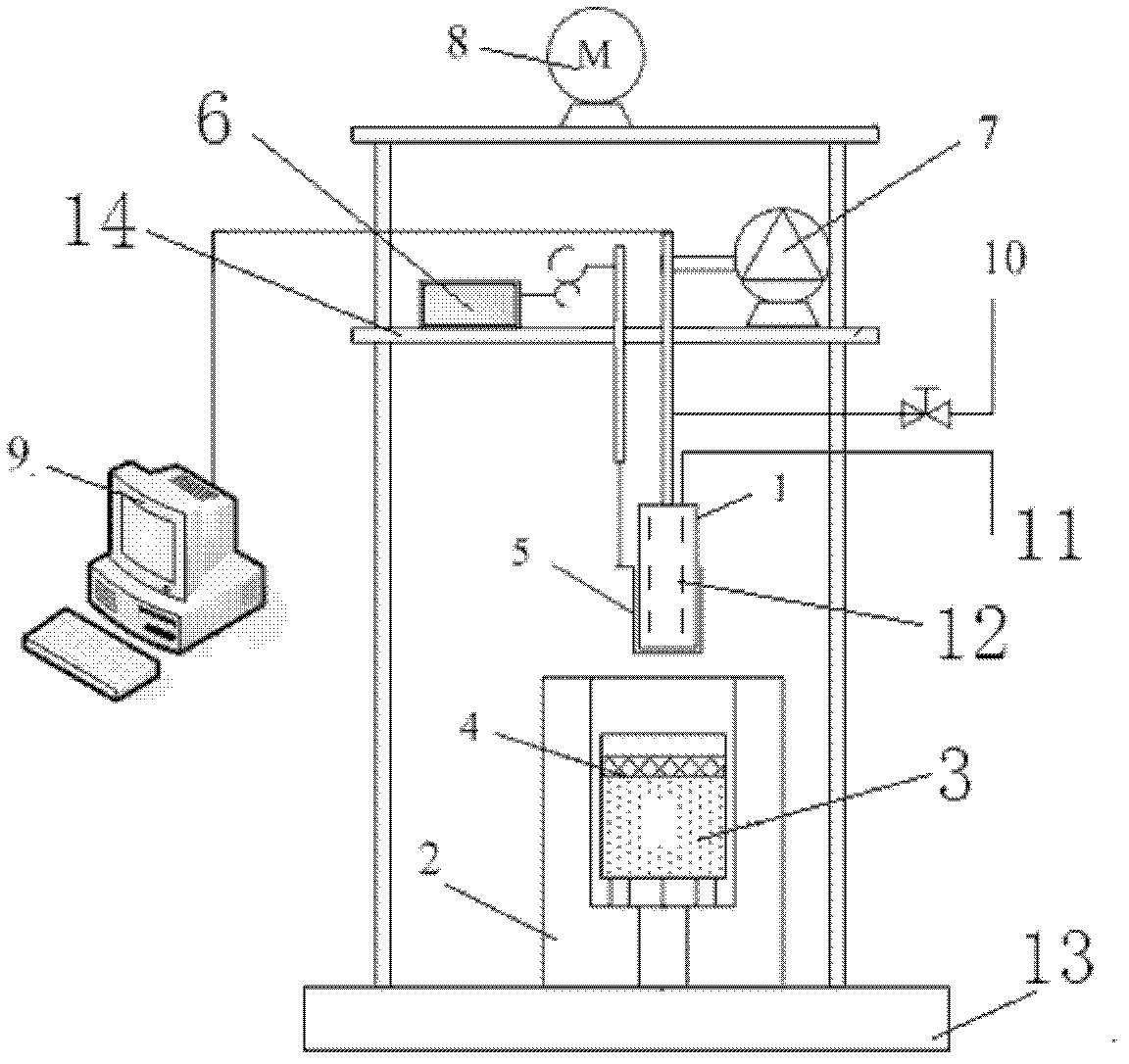

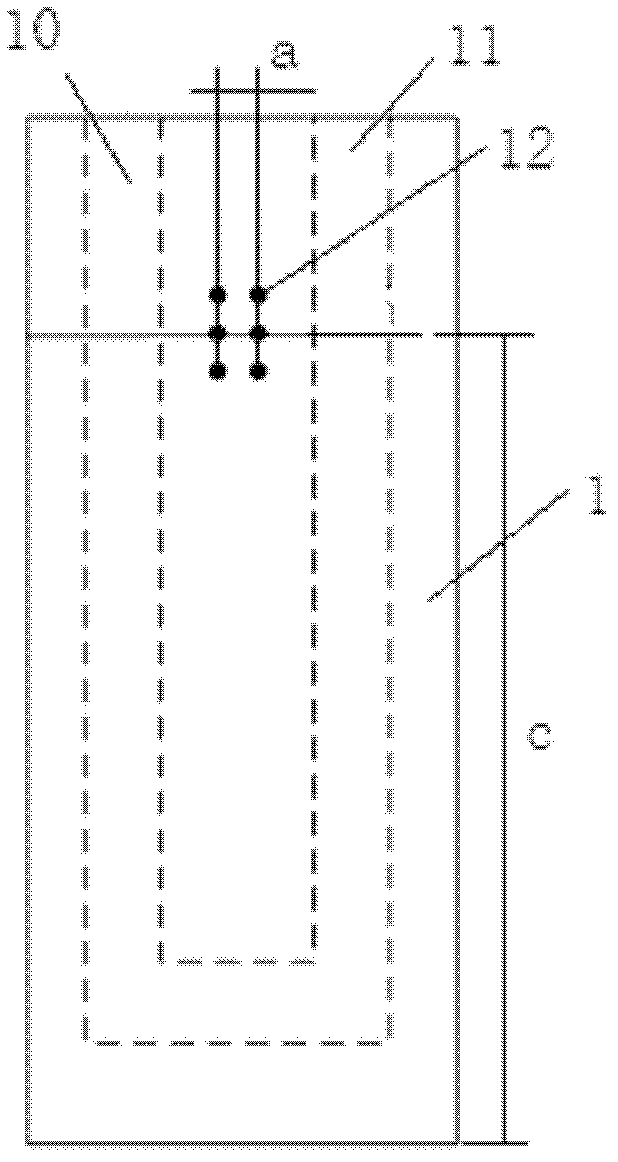

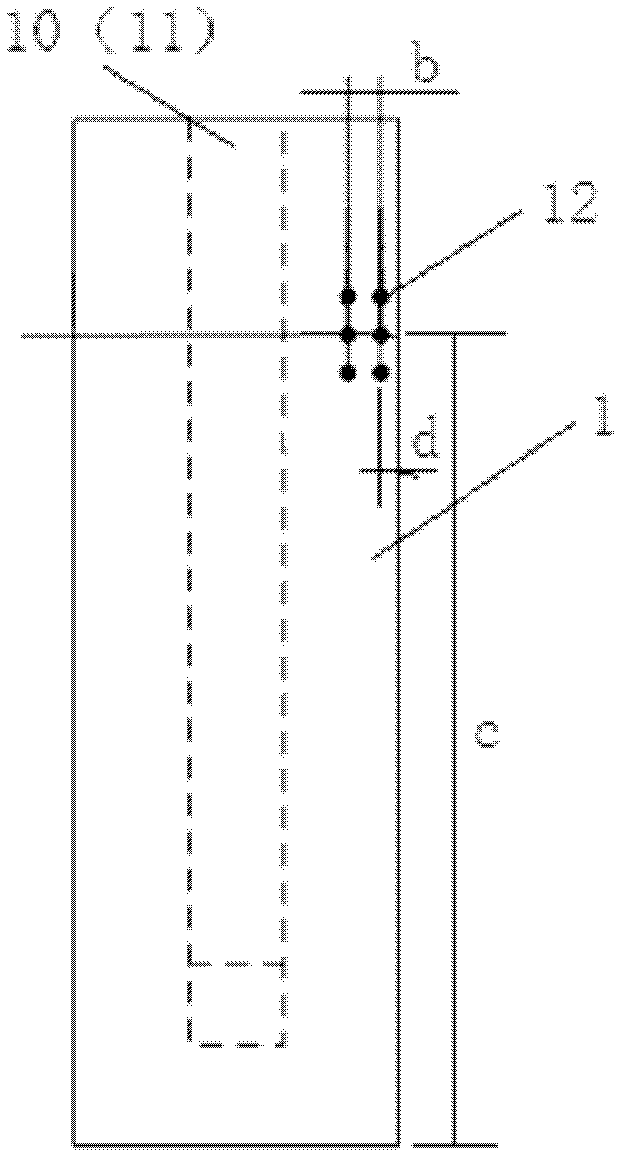

[0028] Referring to the accompanying drawings, the molten steel solidification simulation device in the continuous casting crystallizer includes a machine base 13, a steelmaking furnace 2, a crystallizer 1, a casting motor 6, a vibration motor 7, a cooling system, and a data acquisition system 9. The machine base 13 is provided with two first screw mandrels and second screw mandrels, one end of which is perpendicular to the plane of the machine base, and the other end is connected with the motor drive device 8. On the first screw mandrel and the second screw mandrel, there are provided The first screw mandrel and the second screw mandrel drive the lifting bracket 14 moving in the vertical direction; the steelmaking furnace 2 is arranged on the base 13 and between the first screw mandrel and the second screw mandrel Between; the drawing motor 6 and the vibrating motor 7 are all arranged on the lifting bracket 14, and the crystallizer 1 is provided with a thermocouple 12 and cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com