Temperature adjusting system of integrated sand-blowing dust-blowing environment simulation system and method thereof

A technology for environment simulation and temperature adjustment, which is applied to the testing of machines/structural components, measuring devices, instruments, etc. The heat area is limited and other problems, to achieve the effect of high equipment utilization efficiency, compact structure, and small occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

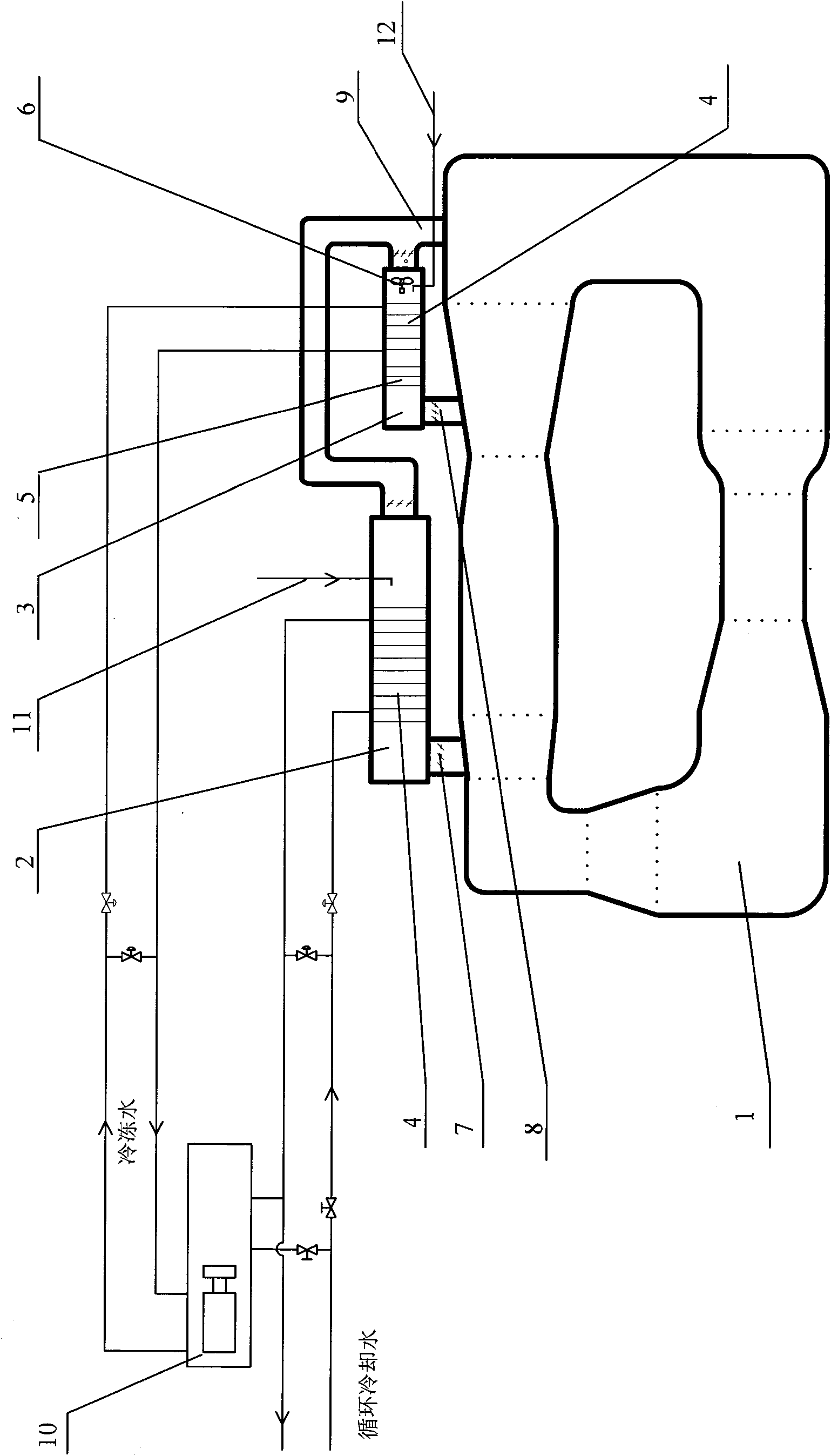

Method used

Image

Examples

Embodiment 1

[0074] An embodiment of the working process in the device according to an embodiment of the invention will be described below:

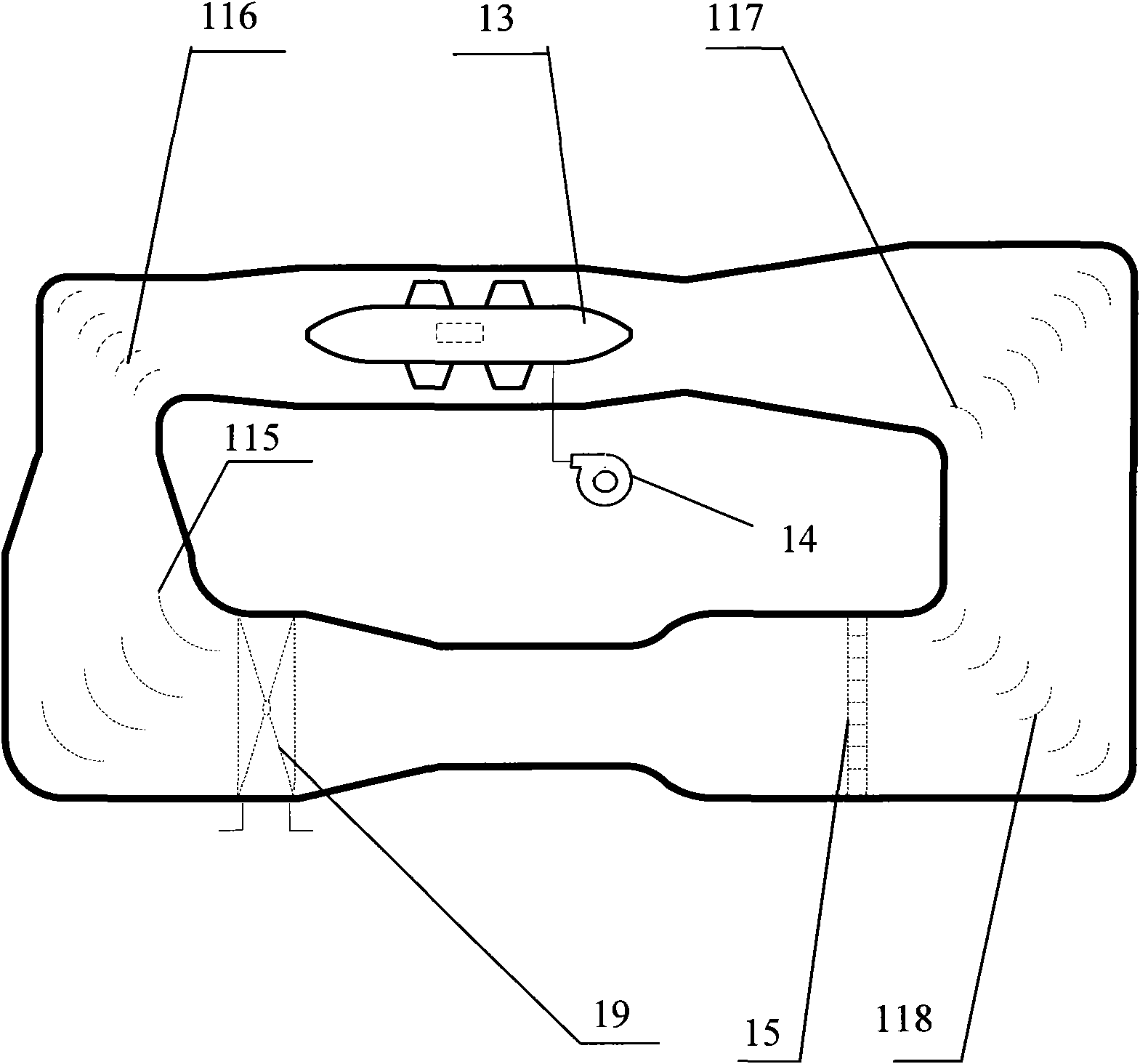

[0075] Please refer to the accompanying drawings, under the drive of the main fan 13, the test air circulates in the circulating air duct 1 and forms a test wind speed that meets the experimental requirements in the test section 101 of the circulating air duct 1. Sand blowing 18-30m / s, low-speed dust blowing 1.5m / s, high-speed dust blowing 8.9m / s, the size of the wind speed can be closed-loop controlled by adjusting the speed of the main fan 13, the aerodynamic layout of the circulating air duct 1 is as follows figure 2 shown. In order to reduce the resistance loss of the circulating air duct 1, four sets of guide vanes 115-118 are provided at the four corners of the circulating air duct 1; in order to improve the air flow quality of the test section 101, a second contraction section is provided upstream of the test section 101 114 and the stabili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com