Three-nozzle layered collaborative printing method

A technology of collaborative printing and nozzles, which is applied in the field of 3D printing technology, can solve the problems that multi-nozzles cannot be printed collaboratively and the printing efficiency is slow, and achieve the effect of seamless connection, improved printing efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

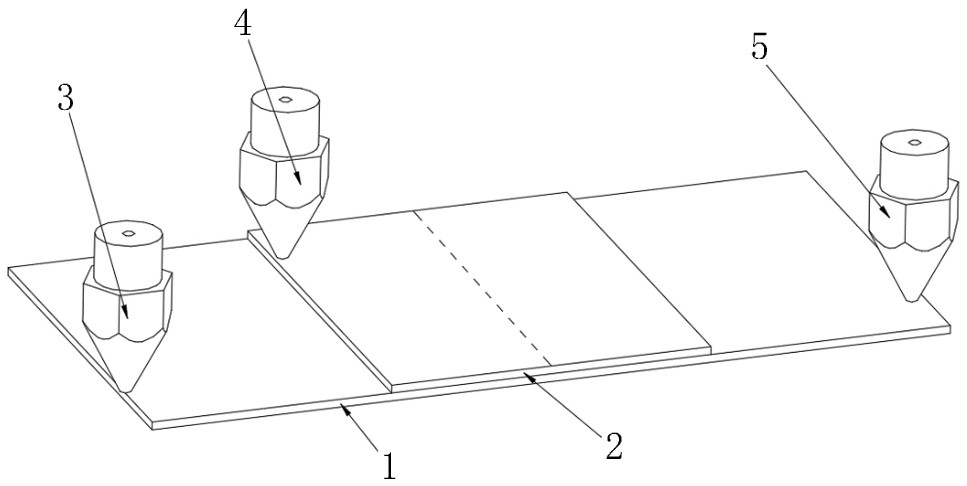

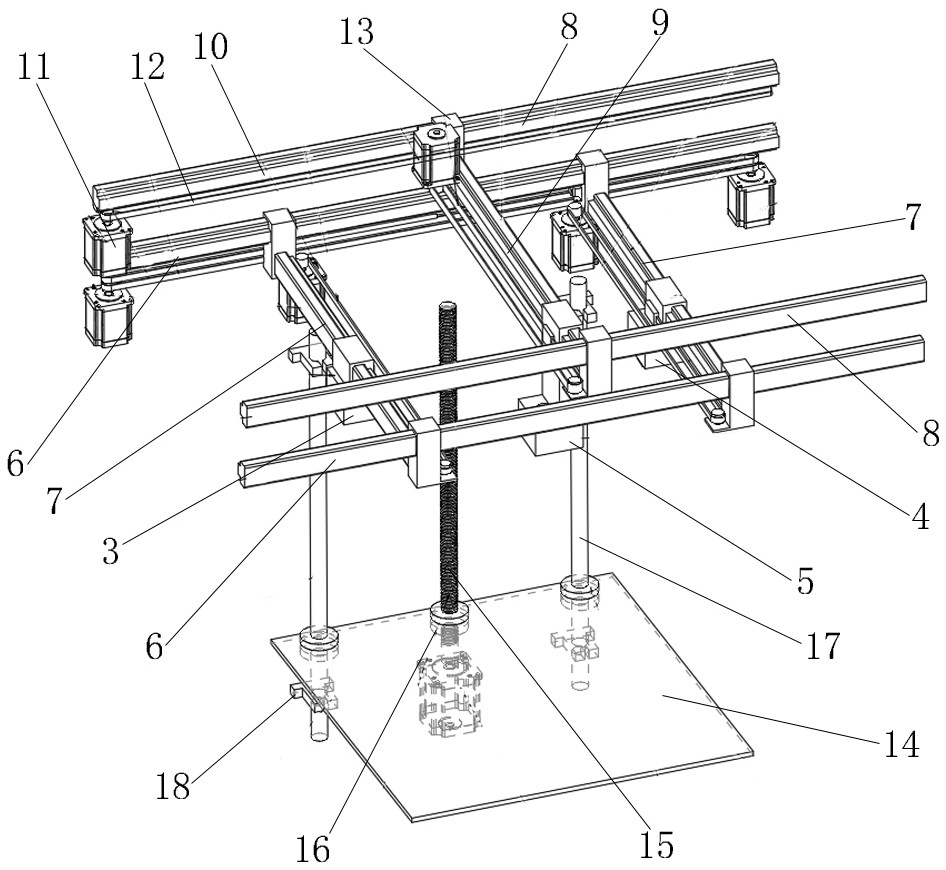

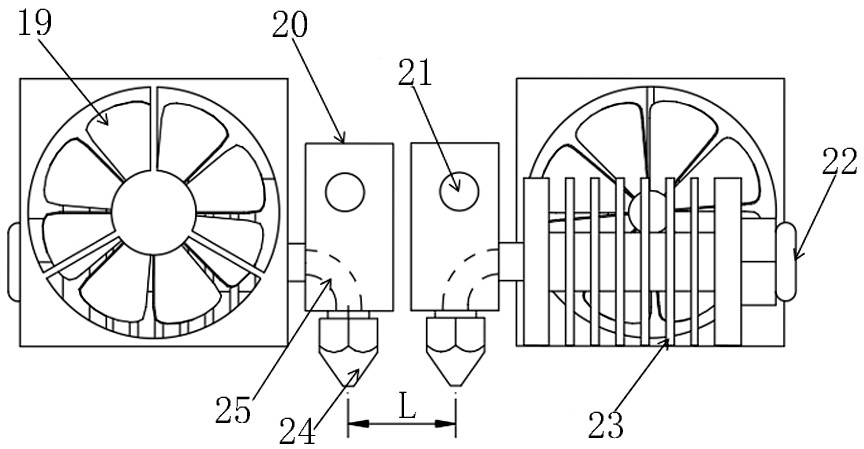

[0031] Such as figure 1 As shown, in the layered cooperative printing method of three nozzles of the present invention, firstly, the left nozzle 3 and the right nozzle 4 are arranged at the same height, and between the left nozzle 3 and the right nozzle 4, there is a layer higher than the left nozzle 3 and the right nozzle 4. An upper nozzle 5 with the thickness of a printing layer is provided with a printing platform below, and the relative distance between the printing platform 14 and the left nozzle 3, the right nozzle 4 and the upper nozzle 5 is adjustable.

[0032] When printing, the specific steps are as follows.

[0033] a. Cut the designed workpiece model horizontally into several layers using slicing software, and the thickness of each layer is consistent with the thickness of the printing layer.

[0034] b. Make path planning for each layer of the workpiece model from bottom to top.

[0035]The three nozzles all move along a straight line. The nozzles first move al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com