Dead-beat model prediction torque control method based on discrete space vector modulation

A technology of space vector modulation and model prediction, applied in the direction of torque ripple control, vector control system, control system, etc., can solve the problems of increased calculation amount, inability to track torque and flux linkage, large amount of calculation, etc., to achieve increased reliability The effect of selecting voltage vector, reducing the number of predictions, reducing torque ripple and calculation amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

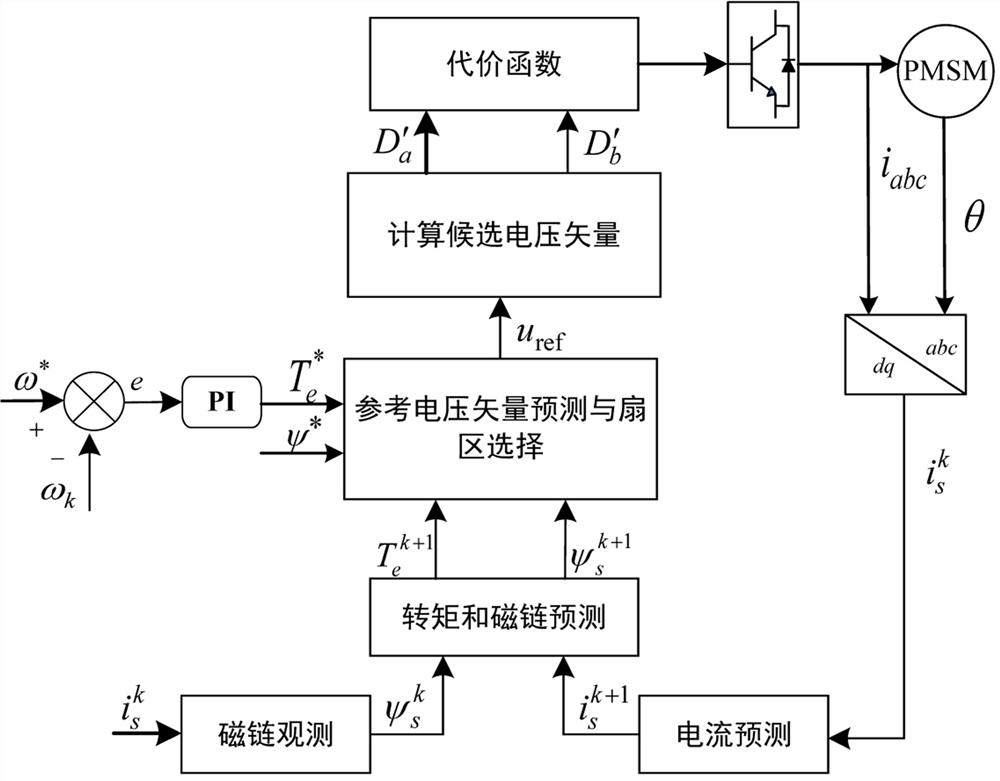

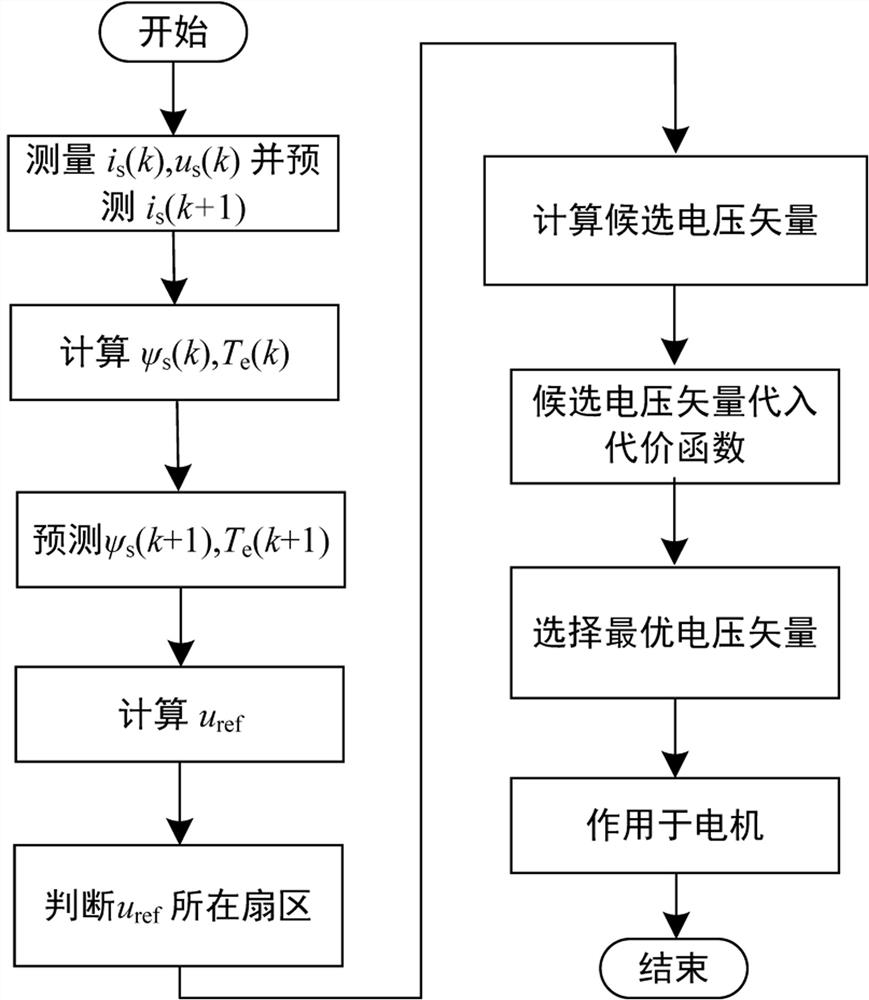

[0062] like figure 1 and figure 2 As shown, this embodiment provides a deadbeat model predictive torque control method based on discrete space vector modulation, including the following steps:

[0063] Step 1, the given rotor angular velocity ω * The deviation from the feedback rotor angular velocity ω is input to the PI controller, and the torque given value is output

[0064] Step 2: Collect the phase currents in the three-phase stationary abc coordinate system, and obtain the two-phase current i in the two-phase stationary αβ coordinate system through Clark transformation α and i β , then i α and i β The two-phase current i in the two-phase rotating dq coordinate system is obtained by Park transformation d and i q ;

[0065] Step 3, using i d and i q Perform current prediction and flux linkage observation to obtain predicted d-axis current q-axis current and magnet links

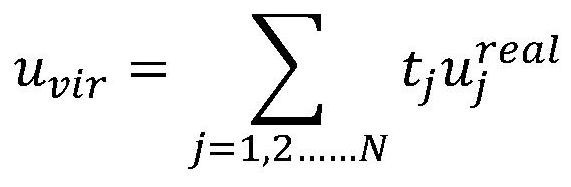

[0066] Step 4, take torque given value Flux linkage given value ψ * , d-axis cu...

Embodiment 2

[0099] This embodiment provides a deadbeat model predictive torque control system based on discrete space vector modulation, the system includes:

[0100] Speed sensor for measuring the angular velocity ω of the motor rotor k ;

[0101] PI controller for a given rotor angular velocity ω * and the rotor angular velocity ω measured by the rotational speed sensor k Deviation output torque given value

[0102] The power sensing device is used for sensing the phase current of the stator three-phase winding of the motor;

[0103] The coordinate transformation module is used to convert the phase currents of the three-phase windings of the stator of the motor to obtain the two-phase current i in the two-phase static αβ coordinate system through Clark transformation α and i β , then i α and i β The two-phase current i in the two-phase rotating dq coordinate system is obtained by Park transformation d and i q ;

[0104] Torque and flux prediction module for utilizing i d ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com