Manufacturing process of rectangular nanocrystalline spraying magnetic core used in medium-high frequency environment

A manufacturing process and nanocrystalline technology, which is applied in the manufacture of magnetic cores, inductors/transformers/magnets, electrical components, etc., can solve the problems of low effective magnetic permeability, difficult to shape, low resistivity, etc., and achieve high space utilization , low cost and high resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

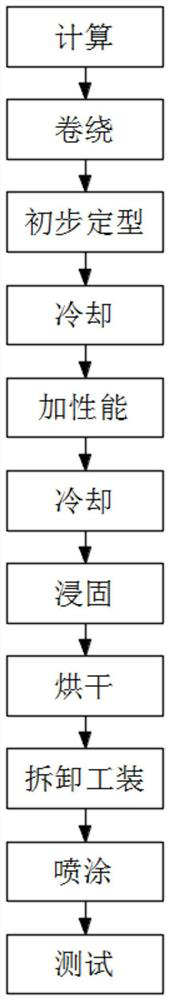

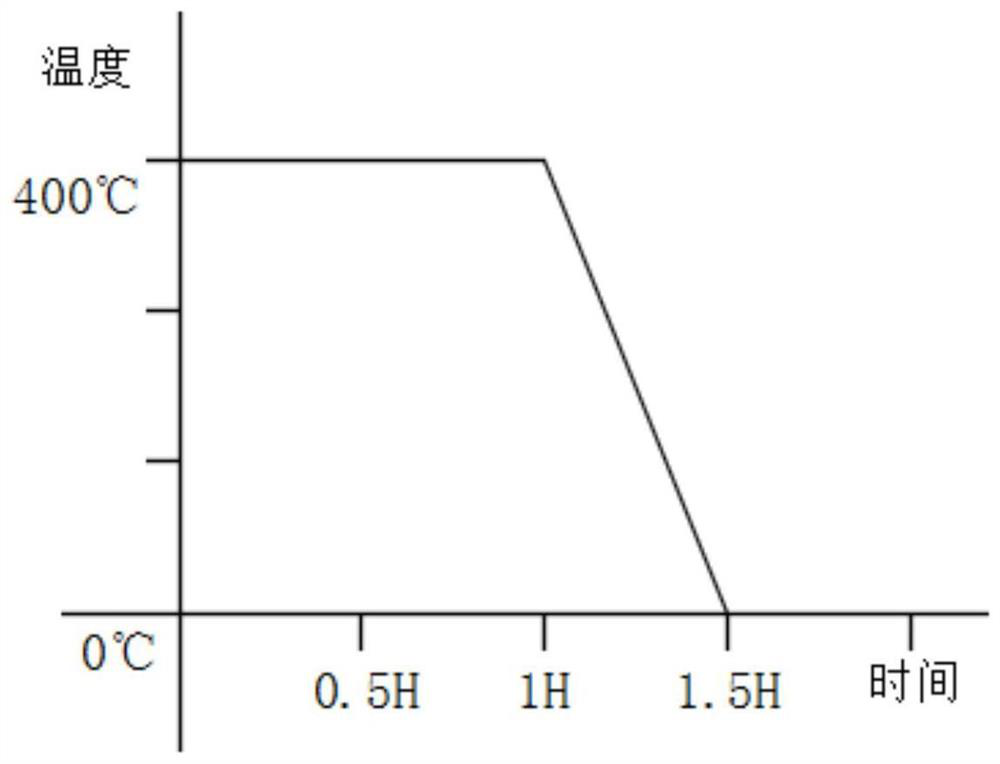

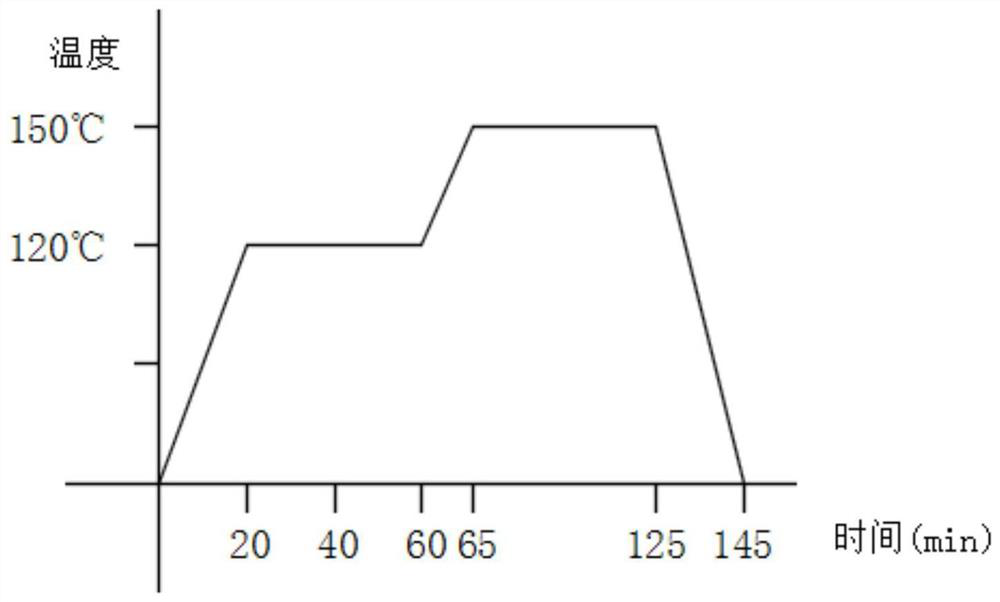

Embodiment 1

[0046]Calculate the size of the 24*32*38*46*30 rectangular magnetic core converted into a toroidal magnetic core to be 38*44.4*30, and use Keruisi 30mm iron-based nanocrystalline ribbon to wind a 38*44.4*30 on the winding machine The ring magnetic core is put into a custom-made stainless steel fixture, sent into an annealing furnace, the stress is removed to set the shape, the tooling is removed to set the shape, and the stress-relieved magnetic core is sent to the heat treatment furnace to increase performance. After the treatment, it is air-cooled and the magnetic core is restored. After reaching room temperature, soak epoxy resin, rinse off the surface glue, and send it to an annealing furnace to dry the glue. After drying, spray the magnetic core with epoxy paint, and spray 10 times on each side to obtain a sprayed magnetic core.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com