Moving speed detection method of nondestructive testing device and system device of moving speed detection method

A non-destructive testing and moving speed technology, applied in radio wave measurement systems, measuring devices, speed/acceleration/shock measurement, etc. Easy to install and apply effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

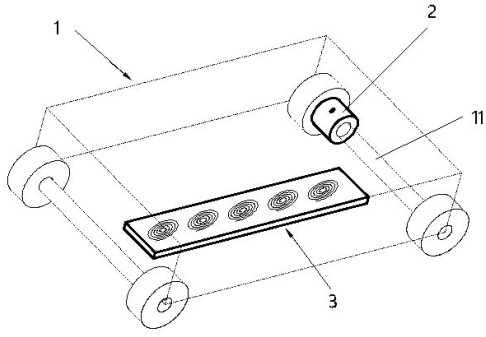

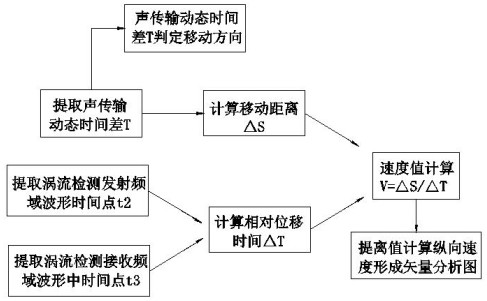

[0039] Such as figure 2As shown, a moving speed detection method of a non-destructive testing device is used to detect and calculate the relative displacement speed between the non-destructive testing device and the detection object, which is characterized in that it is performed by detecting the coil acoustic emission and reception time, and the eddy current frequency domain waveform time The calculation of the displacement velocity, the specific method steps are as follows:

[0040] a. Extract the dynamic time difference T of acoustic transmission: extract the dynamic time t1 of the acoustic transmission between the coil acoustic emission and reception when the detection object and the eddy current detection device are in relative motion, and the on-site calibration acoustic emission and acoustic transmission when the detection object and the eddy current detection device are relatively stationary The acoustic transmission static time t0 between the receiving coils is comp...

Embodiment approach 2

[0059] Such as Figure 8 As shown, the difference from Embodiment 1 is that a coil (34) with an acoustic vibrating plate (35) equidistant from the external eddy current detection coil (31) is set inside the detection device to extract the relatively static on-site environment standard environment where the air flow is relatively static. The sound propagation velocity value V0 is used to calculate the moving distance △S (because the air flow inside the detection device is relatively static)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com