Monitoring Method of Stress Change Based on Fiber Bragg Grating

A technology of optical fiber grating and stress change, which is applied in the direction of measuring, measuring force, and measuring device by measuring the change force of the optical properties of the material when it is stressed, which can solve the problems of poor storage efficiency, difficult information replication, and inconsistent information storage mode. Standardization and other issues to achieve the effect of improving the performance of the duration, improving the efficiency of information storage, and facilitating expansion and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

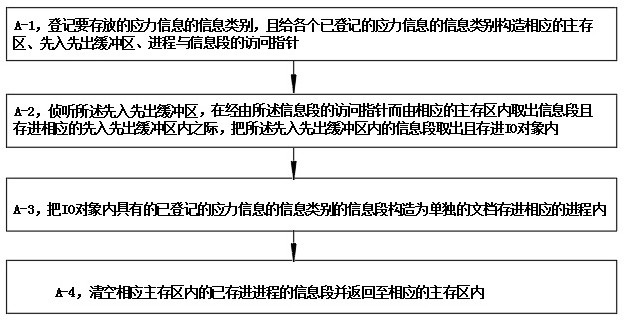

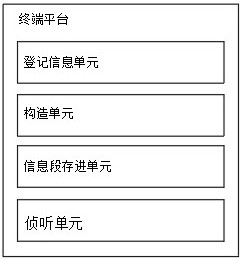

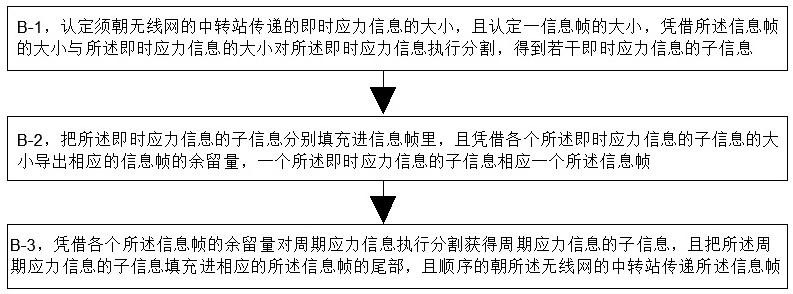

[0082] Such as Figure 1-Figure 5 As shown, the stress change monitoring method based on fiber Bragg grating includes:

[0083]A system for implementing a stress change monitoring method based on a fiber Bragg grating, the system includes a terminal platform and several microprocessors of a fiber Bragg grating-based buried pipeline stress detection platform communicatively connected to the terminal platform, the fiber Bragg grating-based buried pipeline The pipeline stress detection platform also includes a fiber grating sensor, the fiber grating sensor is connected to the spectrum demodulator, and the microprocessor is connected to the spectrum demodulator; the fiber grating-based buried pipeline stress detection platform is based on the fiber grating The real-time stress online monitoring device for buried pipeline welds. In this way, the fiber grat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com