Foundation trench supporting box for underground pipeline open excavation construction

An underground pipeline and open cut technology, which is applied to artificial islands, water conservancy projects, underwater structures, etc., can solve the problems of unsuitable Larsen steel sheet piles, easily damaged pipeline facilities, and inability to assemble, etc., to simplify the support construction process , Improve the construction progress and reduce the installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, so that the advantages and characteristics of the patent of the present invention can be more easily understood by those skilled in the art, so that the protection scope of the present invention can be defined more clearly .

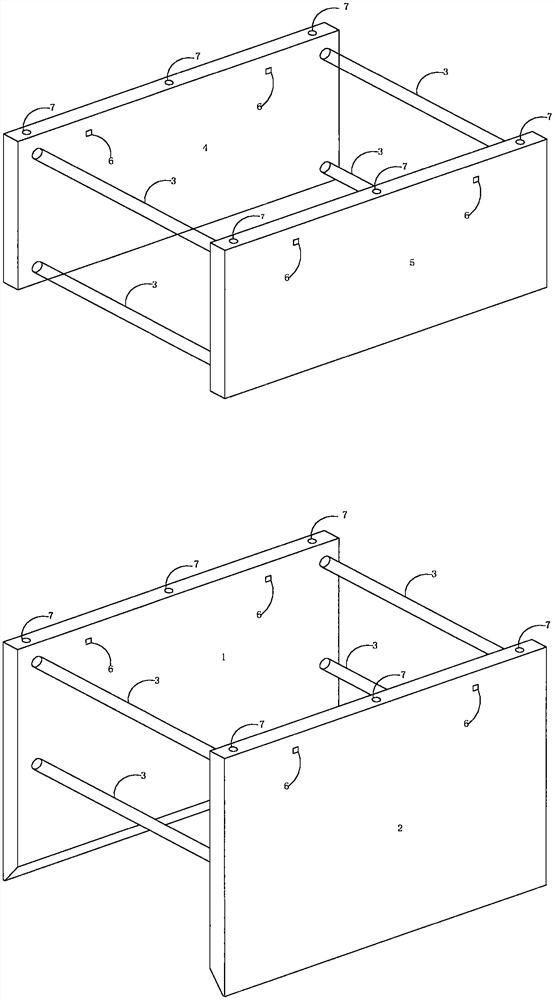

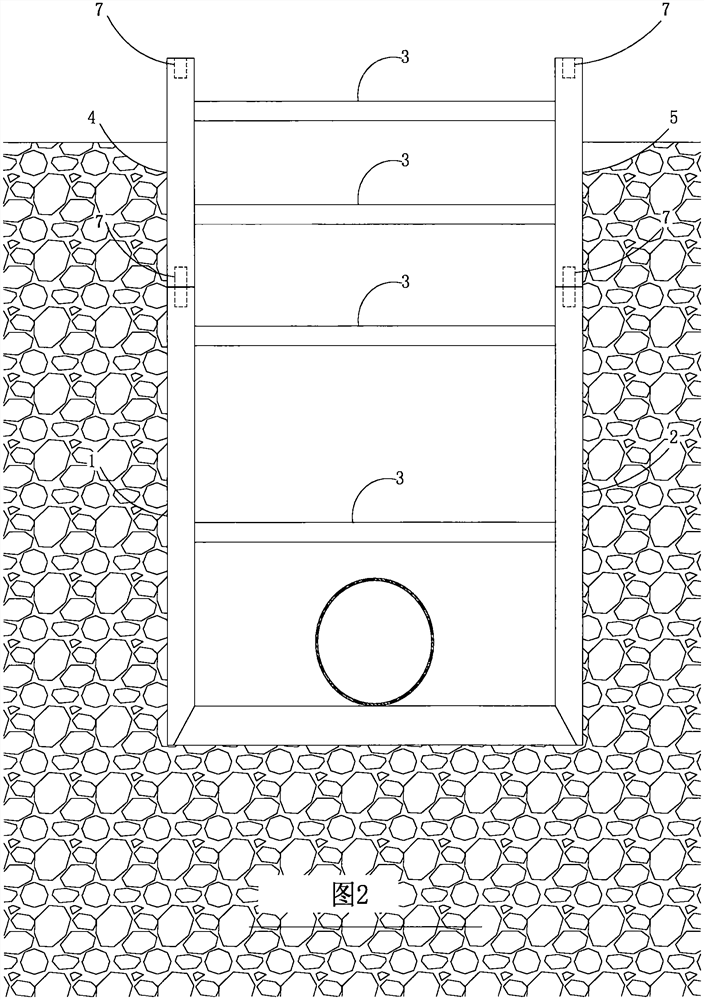

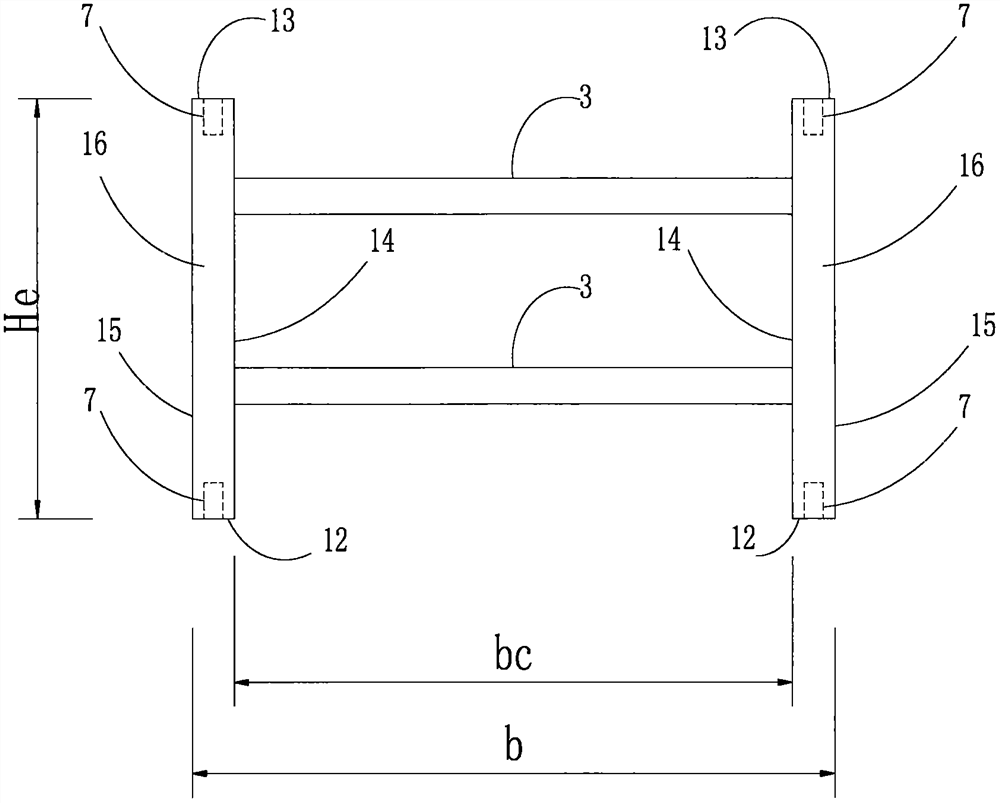

[0031] figure 1 In the shown embodiment, a support box that can be assembled off-site for pipeline foundation trench excavation includes: a bottom support box and a heightened support box; the bottom support box includes a first soil retaining side wall (1) , the second soil retaining side wall (2); the upper and lower layers are parallel to each other and are only installed on the cross braces (3) at both ends of the bottom support box, and the cross braces (3) are connected with the first soil retaining side wall and the second soil retaining side Wall connection, the height Hc of the lowermost edge of the cross brace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com