A method for enriching and extracting gallium from alumina seed separation mother liquor based on biomass materials

A biomass material, alumina technology, applied in the field of enrichment and extraction of gallium, can solve the problems of poor adsorption selectivity and high cost, and achieve the effects of low cost, simple operation, good economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: the preparation of biomass material

[0034] (1) Using surface imprinting technology, using persimmon tannin on the surface of persimmon skin as a functional monomer, Ga 3+ As a template, under the action of cross-linking agent glutaraldehyde, persimmon tannin cross-linked polymer was coated on the surface of persimmon skin: take 0.4 g of dried persimmon skin with a particle size of less than 74 μm, add 30 mL of GaCl with a concentration of 0.05 mol / L 3 solution, stirred for 2 h, then added 2 mL of cross-linking agent glutaraldehyde, and stirred for 24 h in a water bath at 55 °C.

[0035] (2) After the product obtained in step (1) is washed with deionized water, it is put into a HCl solution with a concentration of 1mol / L and soaked for 2 hours until no Ga is detected in the soaking solution. 3+ , and then rinsed with deionized water and dried to obtain a persimmon skin imprinted composite material.

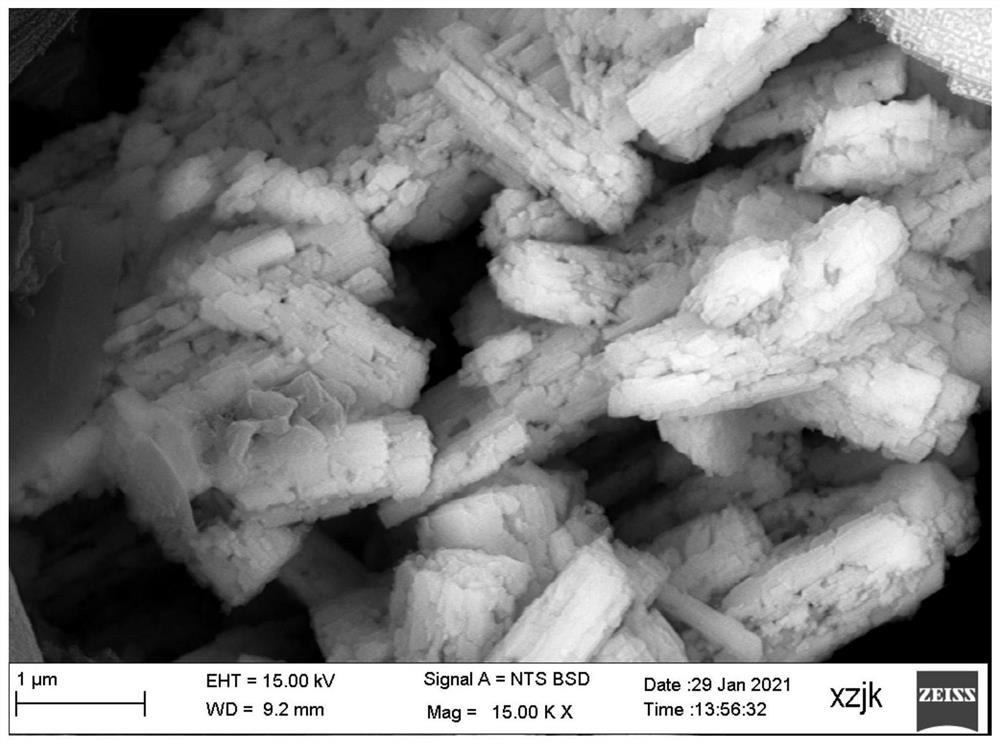

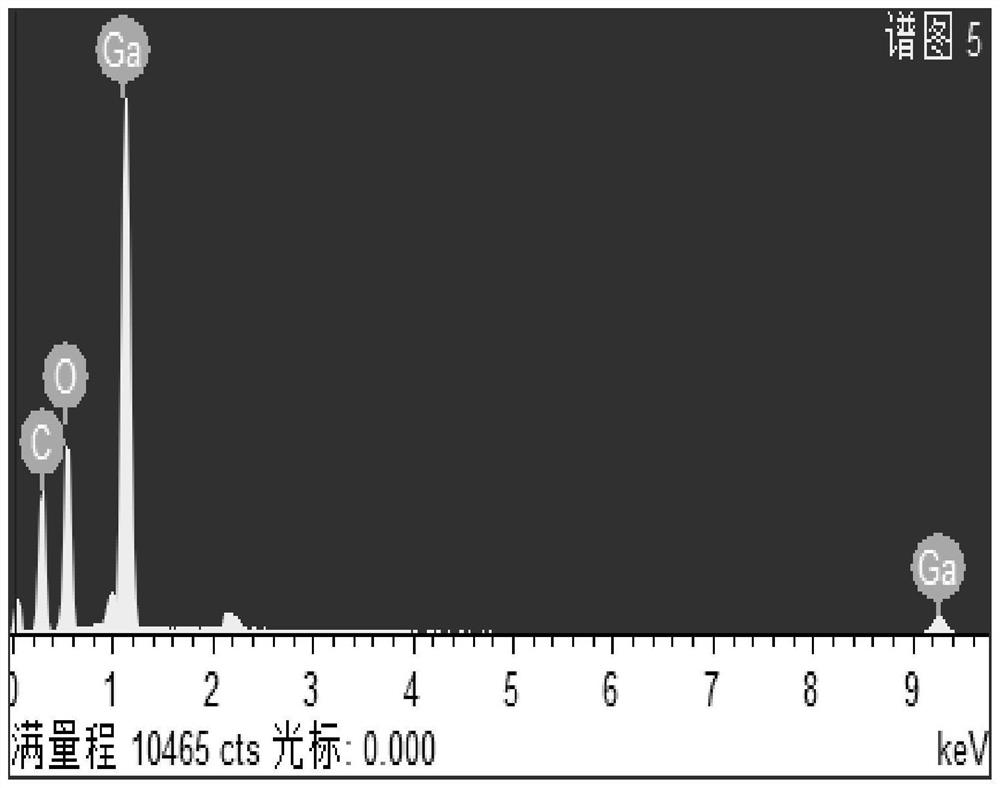

[0036] figure 2 It is the SEM picture of the persim...

Embodiment 2

[0037] Example 2: The dynamic adsorption performance of biomass materials to gallium in alumina seed separation mother liquor

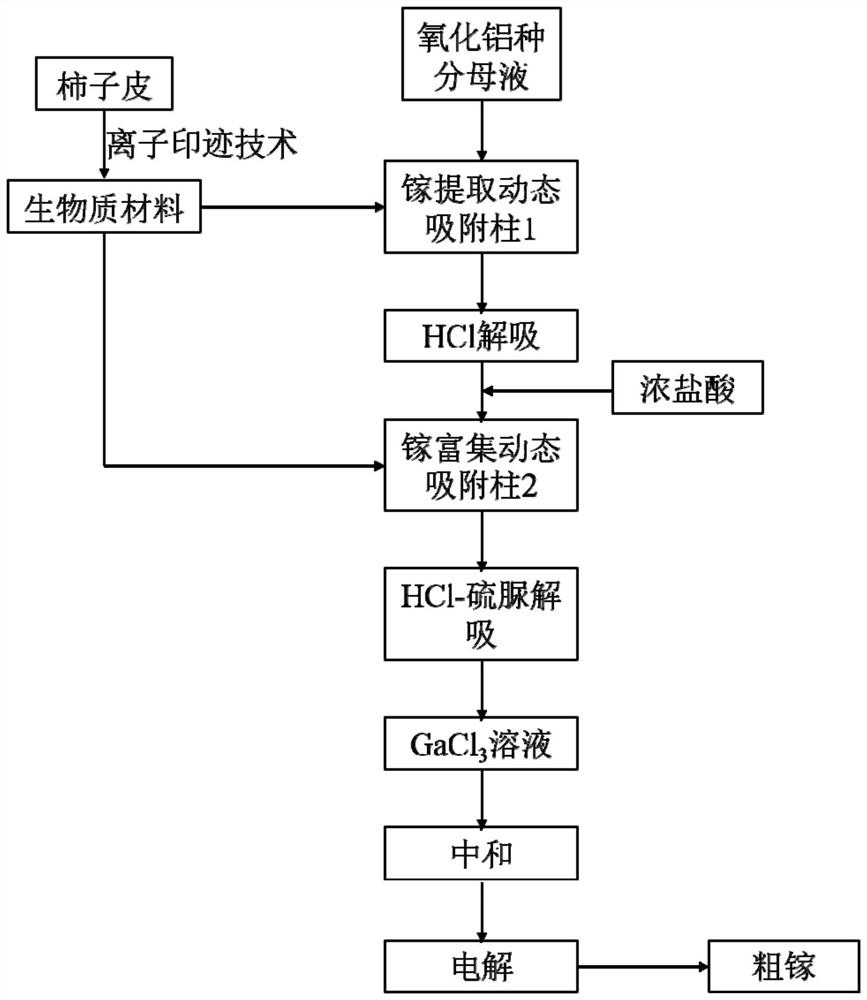

[0038] Implementation steps such as figure 1 shown.

[0039] (1) The biomass material that embodiment 1 obtains is packed in the dynamic glass adsorption column that column length is 300mm, internal diameter 10mm, obtains gallium and extracts dynamic adsorption column 1, makes the aluminum oxide species derivation mother liquor that gallium concentration is 187mg / L in At 40°C, flow through the gallium extraction dynamic adsorption column 1 at a rate of 10BV / h. After 13.3 hours, the gallium concentration at the outlet of the gallium extraction dynamic adsorption column 1 is basically the same as the gallium concentration in the alumina seed separation mother liquor, and the adsorption is stopped;

[0040] (2) With a pump, the HCl solution with a concentration of 1mol / L flows forward through the gallium extraction dynamic adsorption column 1 of step (1...

Embodiment 3

[0042] Example 3: The adsorption performance of biomass material to gallium extraction dynamic adsorption column 1 desorption liquid

[0043] Implementation steps such as figure 1 shown.

[0044](1) The biomass material obtained in Example 1 is packed into a dynamic glass adsorption column with a column length of 300 mm and an internal diameter of 10 mm to obtain gallium-enriched dynamic adsorption column 2, and the acidic desorption solution obtained in Example 2 with concentrated hydrochloric acid Adjust the acid concentration to 6mol / L, and flow through the gallium-enrichment dynamic adsorption column 2 at a rate of 10BV / h. When the gallium concentration at the inlet and outlet of the gallium-enrichment dynamic adsorption column 2 is the same, the adsorption is stopped;

[0045] (2) Use a hydrochloric acid-thiourea desorption solution with a hydrochloric acid concentration of 1.5mol / L (the molar ratio of hydrochloric acid and thiourea is 50:1), flow reversely at 40°C into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com