A pH-responsive ternary composite supramolecular cleaning fracturing fluid

A clean fracturing fluid, ternary composite technology, applied in drilling compositions, wellbore/well components, production fluids, etc., can solve problems that restrict large-scale production applications, cannot meet viscosity requirements, and clean fracturing in synthetic processes The problem of high cost of liquid use, to achieve the effect of universality, low cost, and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a preparation method of a ternary composite supramolecular clean fracturing fluid system, comprising the following steps:

[0027] Weigh the corresponding mass of surfactant according to a certain molar ratio, add it into distilled water, and stir at a speed of 100r / min, until there are no visible particles in the solution, and obtain the ternary composite supramolecular cleaning fracturing fluid.

[0028] In some embodiments, the ternary composite supramolecular cleaning fracturing fluid system is also added with an inorganic base or an inorganic acid for pH adjustment.

[0029] In some embodiments, the inorganic base is sodium hydroxide or potassium hydroxide.

[0030] In some embodiments, the inorganic acid is hydrochloric acid, sulfuric acid, or phosphoric acid.

[0031] In some embodiments, 4-carboxybenzaldehyde, aniline forms a supramolecular dynamic covalent bond under basic conditions.

[0032] The invention provides the application of t...

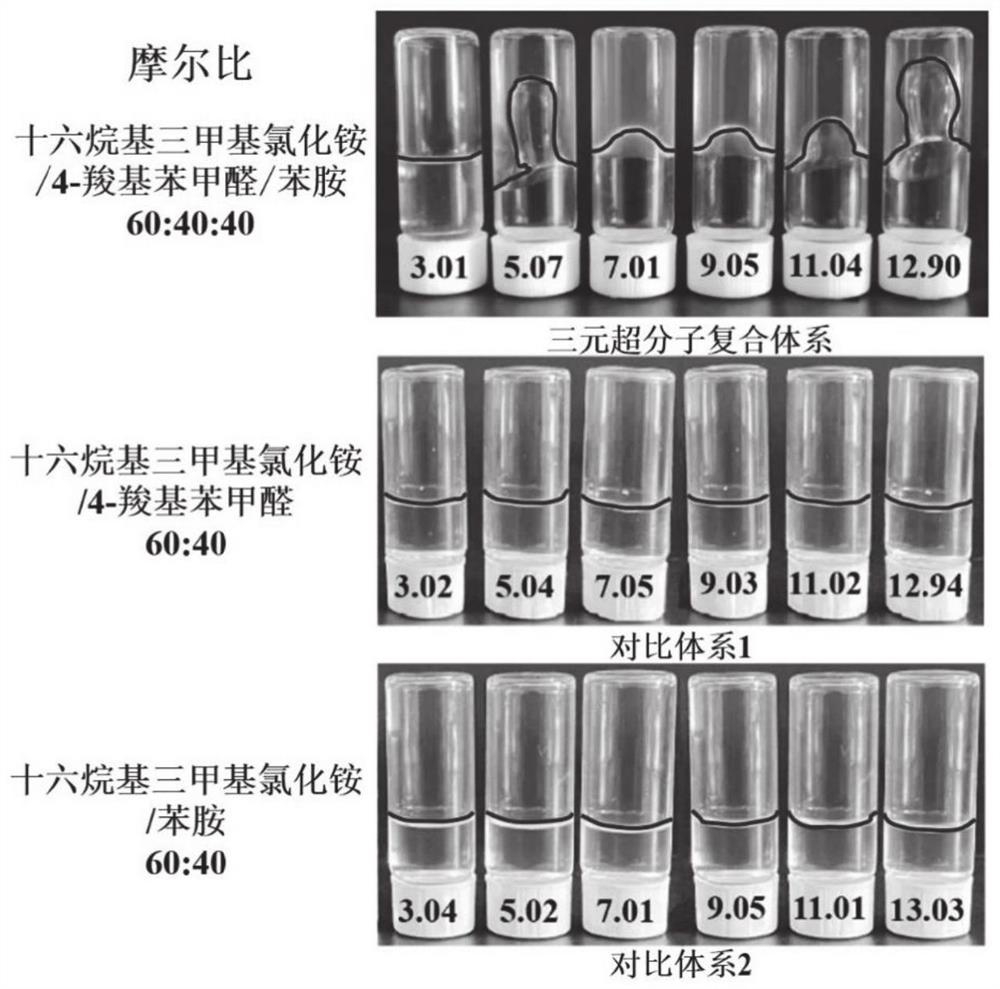

Embodiment 1

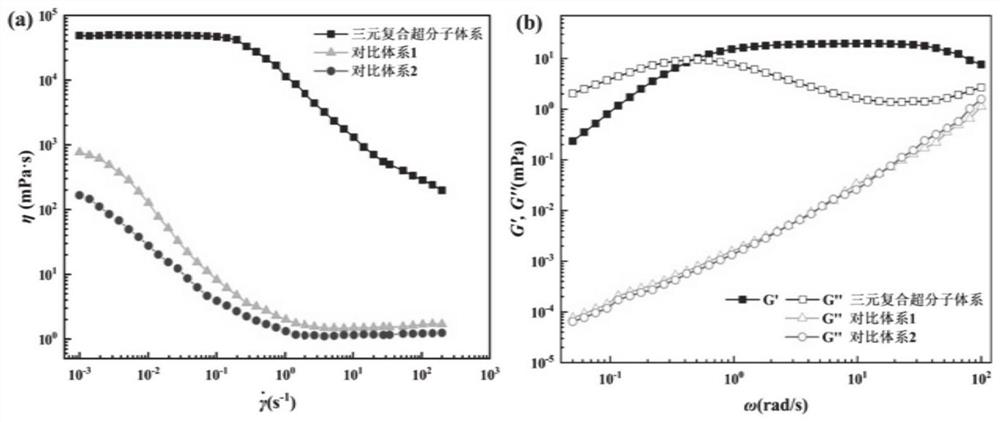

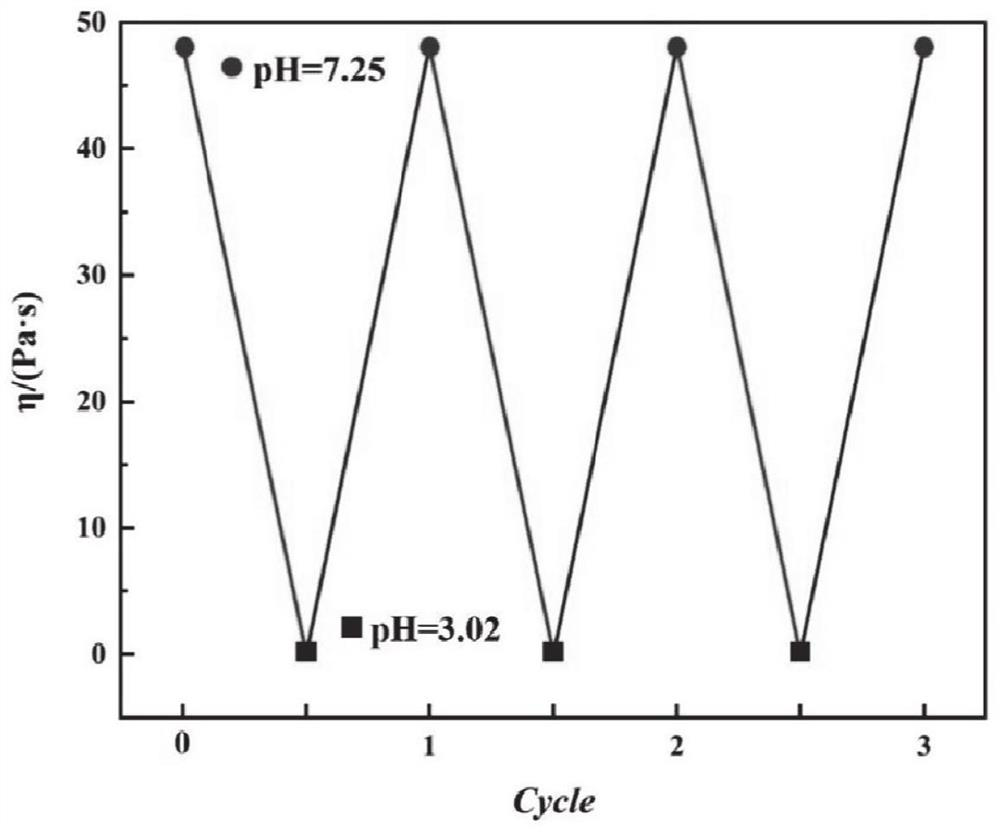

[0035] The continuous fluid state transition behavior of the ternary composite supramolecular system at pH is achieved by the formation and cleavage of supramolecular dynamic covalent bonds (imine bonds) by 4-carboxybenzaldehyde and aniline under alkaline conditions. By adjusting the pH value, the ternary compound supramolecular clean fracturing fluid system can obtain more than 3 cycles of morphological changes from spherical micelles to worm-like micelles, and the appearance is from transparent gel-like fluid to low-viscosity fluid change between. This pH-responsive ternary composite supramolecular system can meet the viscosity requirements of fracturing fluids, and can also reduce the adsorption loss in the formation, and has more research value in the field of enhanced oil recovery.

[0036]

[0037] This embodiment provides a pH-responsive ternary composite supramolecular cleaning fracturing fluid. The surfactant in the cleaning fracturing fluid is composed of A: hexad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com