Carbon-based compound enzyme fertilizer and preparation method thereof

A compound enzyme and fertilizer technology, applied in organic fertilizers, inorganic fertilizers, excretion fertilizers, etc., can solve the problems of comprehensive nutrition of enzyme fertilizers, difficult to solve crop growth problems, short enzyme fertilizer activity retention time, etc., to achieve enhanced The effects of stress-resistant growth and reproduction, enhanced osmotic adjustment ability, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

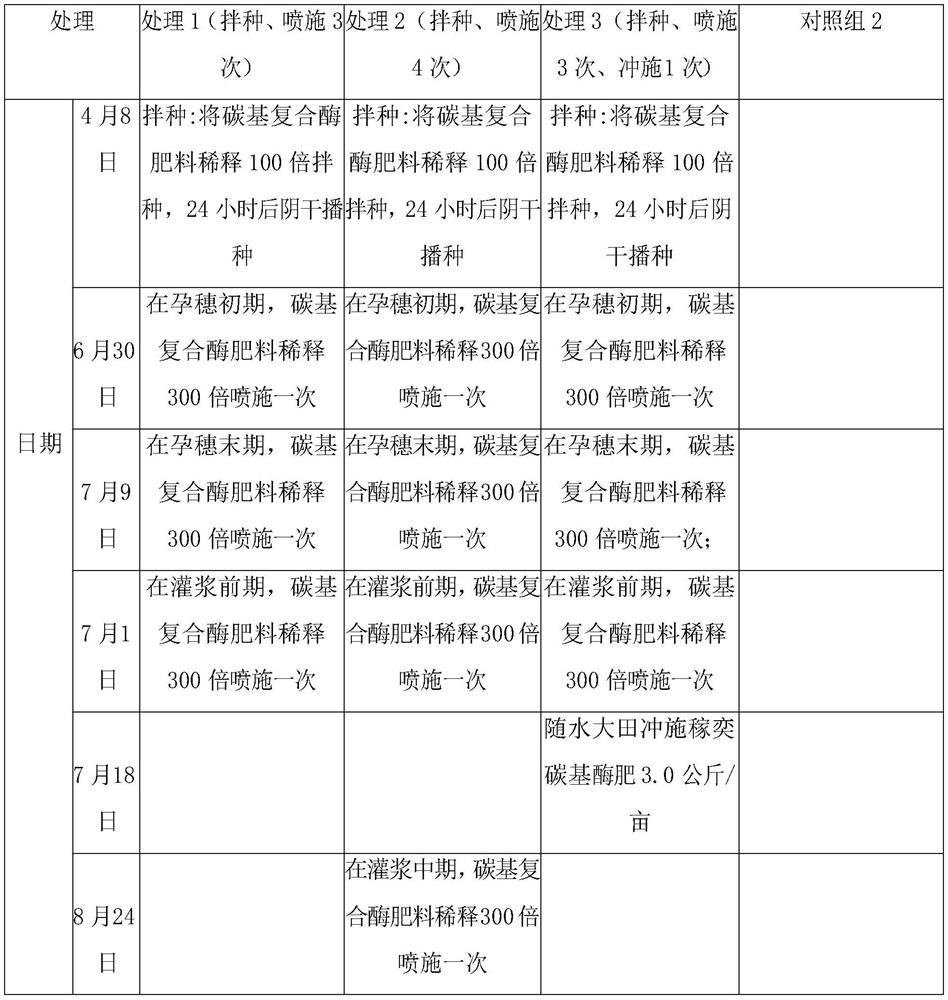

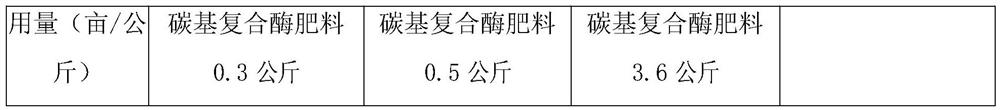

Examples

Embodiment 1

[0034] The preparation method of carbon-based compound enzyme fertilizer comprises the following steps:

[0035] (1) Weigh 10kg of agricultural, forestry and animal waste fermentation liquid, 0.15kg of humic acid, 1kg of β-amylase, 1kg of vacuolar invertase and cytoplasmic invertase, 1kg of serine protease and metalloprotease, 3kg of Bacillus subtilis , yeast 4kg, calcium nitrate 0.03kg, potassium nitrate 0.07kg, diammonium phosphate 0.05kg, magnesium sulfate 0.1kg, ferrous sulfate, manganese sulfate, zinc sulfate, boric acid, mixed rare earth nitrate 0.03kg each, multi-source plant compound Enzyme 10kg;

[0036] (2) Fermentation liquid of agricultural, forestry and livestock waste, humic acid, β-amylase, phagocytic invertase and cytoplasmic invertase, serine protease and metalloprotease, Bacillus subtilis, saccharomyces, calcium nitrate, potassium nitrate, Diammonium hydrogen phosphate, magnesium sulfate, ferrous sulfate, manganese sulfate, zinc sulfate, boric acid, mixed ra...

Embodiment 2

[0038] The preparation method of carbon-based compound enzyme fertilizer comprises the following steps:

[0039] (1) Weigh 40kg of agricultural, forestry and animal waste fermentation broth, 0.8kg of humic acid, 10kg of α-amylase, 9kg of vacuolar invertase and 9kg of cytoplasmic invertase, 7kg of metalloprotease, 18kg of Bacillus subtilis, and 22kg of yeast , calcium nitrate 0.15kg, potassium nitrate 0.25kg, diammonium hydrogen phosphate 0.18kg, magnesium sulfate 0.35kg, ferrous sulfate, manganese sulfate, zinc sulfate, boric acid 0.1kg each, mixed rare earth nitrate 0.18kg, multi-source plant compound enzyme 23kg ;

[0040] (2) The fermented liquid of agricultural, forestry and animal waste, humic acid, α-amylase, sac-type invertase and cytoplasmic invertase, metalloprotease, Bacillus subtilis, yeast, calcium nitrate, potassium nitrate, dihydrogen phosphate Ammonium, magnesium sulfate, ferrous sulfate, manganese sulfate, zinc sulfate, boric acid, mixed rare earth nitrate, an...

Embodiment 3

[0042] The preparation method of carbon-based compound enzyme fertilizer comprises the following steps:

[0043] (1) Weigh 80kg of agricultural, forestry and livestock waste extract, 1kg of humic acid, 20kg of α-amylase, 35kg of vacuolar invertase, 15kg of serine protease, 30kg of Bacillus subtilis, 35kg of yeast, 0.25kg of calcium nitrate, nitric acid Potassium 0.6kg, diammonium hydrogen phosphate 0.45kg, magnesium sulfate 0.7kg, ferrous sulfate, manganese sulfate, zinc sulfate, boric acid 0.25kg each, mixed rare earth nitrate 0.4kg, multi-source plant compound enzyme 35kg;

[0044] (2) extracting agricultural, forestry and livestock waste, humic acid, α-amylase, phagocytic invertase, serine protease, Bacillus subtilis, yeast, calcium nitrate, potassium nitrate, diammonium hydrogen phosphate, magnesium sulfate, Ferrous sulfate, manganese sulfate, zinc sulfate, boric acid, mixed rare earth nitrate, and multi-source plant compound enzyme are mixed and heated to 30°C, then ferme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com