Preparation method of self-assembled flaky VS2/S nanosheet

A self-assembly, nanosheet technology, applied in the preparation/purification of sulfur, chemical instruments and methods, vanadium compounds, etc., can solve the problems of hysteretic electrochemical reaction, poor rate performance, etc. Active sites, the effect of increasing interlayer space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] First dissolve sodium metavanadate in 50ml of absolute ethanol, and stir at room temperature for 30min at a speed of 500r / min to obtain a mixed solution with a vanadium source concentration of 0.16mol / L; slowly add 0.07g of hexadecyltrimethyl bromide Ammonium chloride, stirred at room temperature at a speed of 600r / min for 20min; according to the molar ratio of V:S of 1:4, thioacetamide was added to the solution, and stirred at room temperature at a speed of 600r / min for 60min to obtain the sulfur source A mixed solution with a concentration of 0.64mol / l, transfer the mixed solution to a polytetrafluoroethylene lining with a filling ratio of 55%, conduct a solvothermal reaction at 160°C for 24 hours, and collect the product by suction filtration with water and absolute ethanol Alternately washed three times and freeze-dried for 12 hours to obtain a vanadium-sulfur composite material.

Embodiment 2

[0030] First, dissolve sodium metavanadate in 50ml of absolute ethanol, and stir for 30min at room temperature at a speed of 600r / min to obtain a mixed solution with a vanadium source concentration of 0.13mol / L; slowly add 0.1g of hexadecyltrimethyl bromide Ammonium chloride, stirred at room temperature at a speed of 500r / min for 30min; according to the molar ratio of V:S of 1:4.5, thiourea was weighed and added to the solution, and stirred at room temperature at a speed of 500r / min for 60min to obtain the sulfur source concentration It is a mixed solution of 0.59mol / L, and the mixed solution is transferred to the lining of polytetrafluoroethylene, the filling ratio is 65%, and the solvothermal reaction is carried out at 180°C for 18h, and the product is collected by suction filtration, and then water and absolute ethanol are alternately Washed three times and freeze-dried for 12 hours to obtain a vanadium-sulfur composite material.

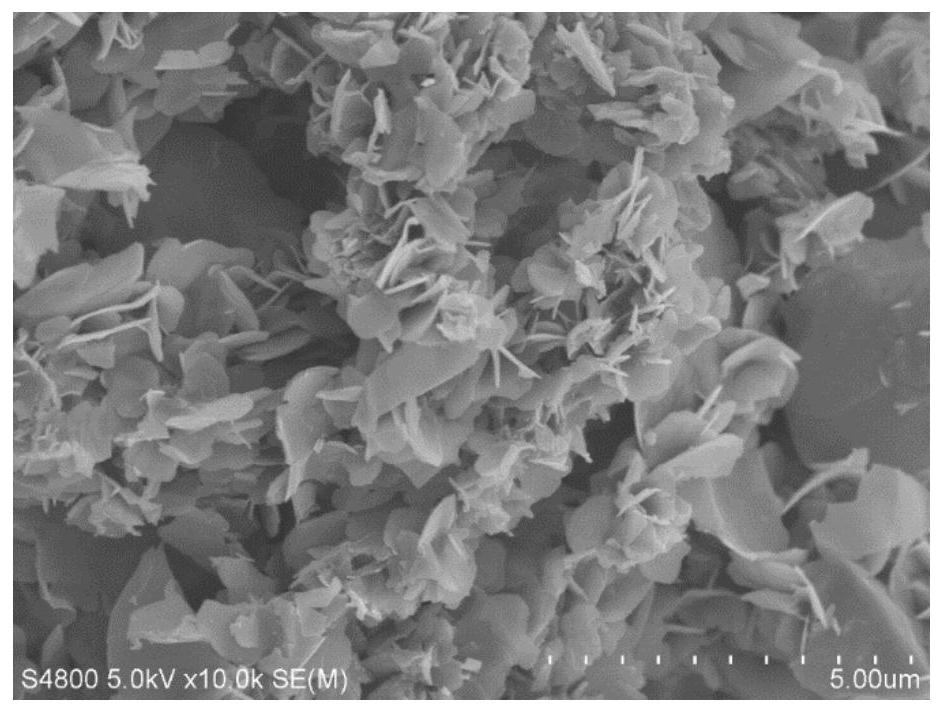

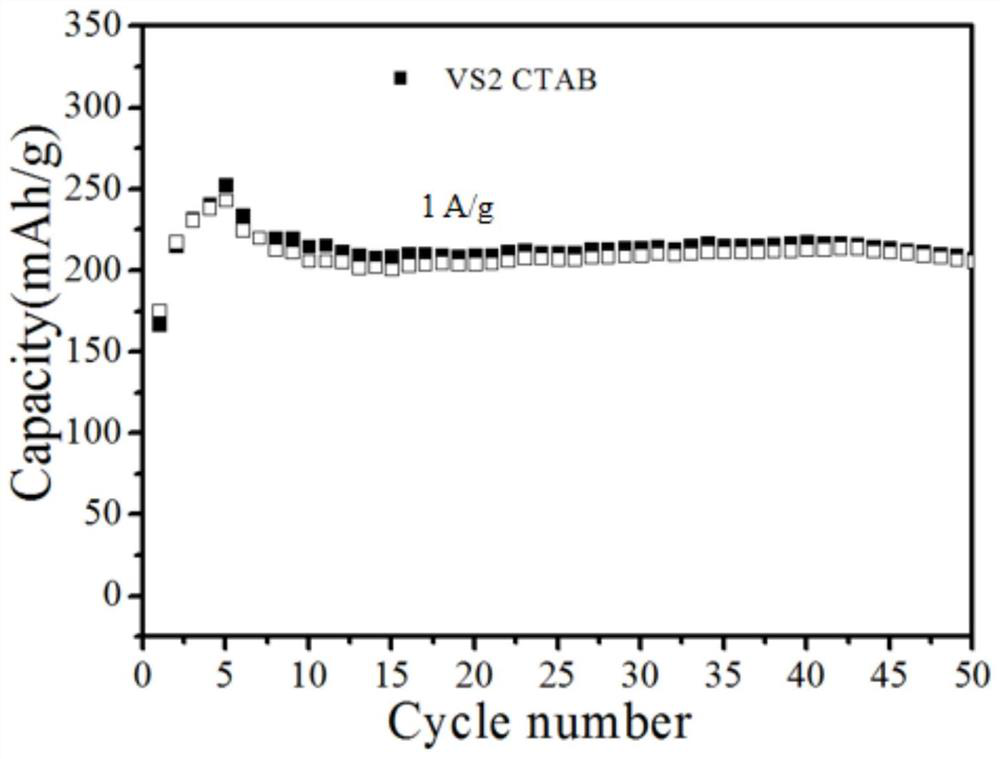

[0031] figure 1 For the self-assembled sh...

Embodiment 3

[0035] First, dissolve vanadium chloride in 50ml of absolute ethanol, and stir for 30min at room temperature at a speed of 700r / min to obtain a mixed solution with a vanadium source concentration of 0.2mol / L; slowly add 0.3g of hexadecyltrimethyl bromide For ammonium, stir at room temperature at a speed of 700r / min for 10min; weigh thiourea amine at a molar ratio of V:S of 1:5 and add it to the solution, and stir at room temperature for 60min at a speed of 700r / min to obtain a sulfur source concentration of 1mol / L mixed solution, transfer the mixed solution to the inner liner of polytetrafluoroethylene, the filling ratio is 75%, carry out solvothermal reaction at 200°C for 12h, collect the product by suction filtration and wash it alternately with water and absolute ethanol three times And freeze-dried for 12 hours to obtain a vanadium-sulfur composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com