A system and method for detecting cracks in a scraper conveyor chain

A scraper conveyor and chain technology, applied in conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of high equipment cost, excessive dust, limited crack detection methods, etc., and achieve high reliability and investment cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

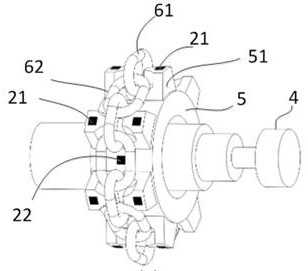

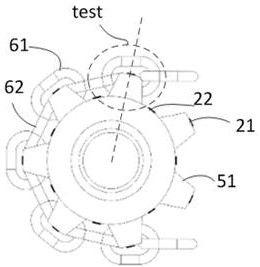

[0039] Referring to Fig. 1, the drive sprocket belt chain ring is shown from two perspectives, the scraper conveyor comprises a stator 4 and a drive sprocket 5, and the chain is wound on the peripheral wall of the drive sprocket 5 and meshed with the drive sprocket 5 , the chain is formed by connecting a plurality of basic link structures in series.

[0040] Specifically, the basic link structure is formed by connecting a horizontal link 62 and a vertical link 61 in series, and the horizontal link 62 and the vertical link 61 are perpendicular. Correspondingly, a plurality of groups of projections 51 protrude from the peripheral wall of the driving sprocket 5, and the plurality of groups of projections 51 are evenly spaced around the peripheral wall of the driving sprocket 5, and each group of projections 51 is Composed of two projections 51 that are mirror images of each other, each vertical link 61 is clamped between a set of projections 51 and parallel to the mirror image pl...

Embodiment 2

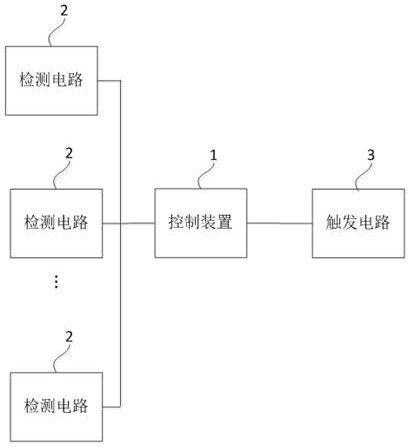

[0056] This embodiment discloses a method for detecting cracks in the chain of a scraper conveyor, which is implemented based on the system of the embodiment. The method includes: generating a position trigger signal every time a basic link structure is rotated; When the position trigger signal is selected, the detection circuit at the test position is selected to perform a test. Each test includes: sending an excitation signal to the test position to generate an alternating magnetic field, and obtaining the feedback signal generated by electromagnetic induction with the chain link. When the feedback signal changes abnormally, it is determined that the basic link structure corresponding to the currently excited detection circuit has a crack.

[0057] Further, the method further includes: in the first test mode, when the chain rotates once, when the position trigger signal is received once, select the horizontal chain ring detection point / two vertical chains of the test position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com