Fresh air pipeline and production process of fresh air pipeline

A technology for fresh air ducts and production processes, applied in duct layout, tubular items, other household appliances, etc., can solve problems such as poor ventilation, unevenness, and bulkiness, and achieve the effect of convenient construction, installation, positioning, and density reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Making molds:

[0041] The content of the mold is generally two petals of the product. The appearance size of each petal is 235mmX51.5mmX1200mm, and it is divided into male and female, which is convenient for positioning and synthesizing a square pipe. A central column is set in the middle of the pipe to make the pipe have a strong weighing capacity and no deformation.

[0042] 2. Pipe forming:

[0043] A. Put the mold into the injection foaming machine and start the equipment;

[0044] B. Mold closing: Preheat the mold so that the surface temperature of the mold reaches the melting point of PP;

[0045] C. Feed material: Make the raw material enter the mold through the material gun.

[0046] D. Pass steam into the mold in three steps:

[0047] (1) Steam scour: Steam scours from top to bottom to expel air from the steam chamber and condensed water to flow out. During this process, open the upper steam inlet valve and the lower condensate drain valve.

[0048] (2...

Embodiment 2

[0063] 1. The product is molded by EPP special equipment. The pipe size of 100mmX100mmX1200mm requires a professional mold to be demolded by the mold core-pulling process. After the molding is completed, the product is demoulded together with part of the core-pulling model. The demoulded product needs to be placed The product is separated from the core-pulling on the special tooling, and the product is considered as the end of production after the separation is completed.

[0064] The third step pipeline synthesis in Example 1 was omitted.

Embodiment 3

[0066]The size of the two-petal pipe is 235mmX31.5mmX1200mm, and the size of the finished product is 235mmX55mmX1200mm. Others are the same as plan 1.

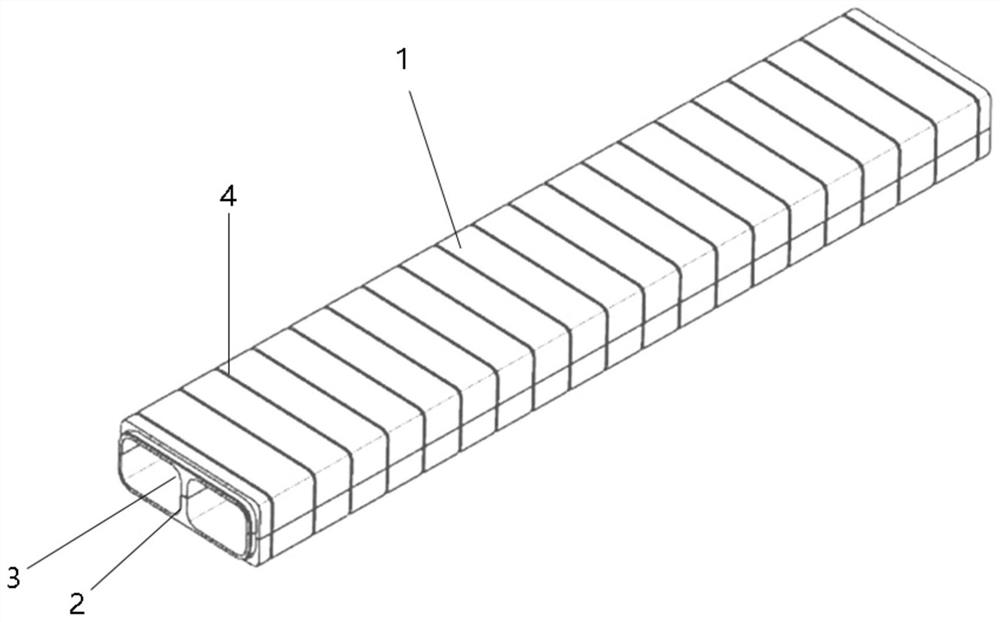

[0067] Such as figure 1 Shown:

[0068] The cross-section of the finished fresh air duct 1 is rectangular, and has the effects of lightness, environmental protection, flame retardancy, smooth ventilation, noise reduction, easy installation, and beauty. A load-bearing column 2 is arranged in the middle of the pipeline 1 to withstand heavy pressure. The inner corner of the pipe 1 has an inner chamfer 3 to ensure smooth ventilation and noise reduction. The outer wall of the pipeline 1 is provided with a plurality of bar-shaped slots 4 at intervals, which is convenient for construction, installation and positioning, and prevents the pipeline from slipping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com