Signal transmission method for downhole measurement and control system

A technology of measurement and control system and transmission method, which is applied in the directions of measurement, earthwork drilling and production, wellbore/well components, etc., and can solve problems such as single-core transmission signal, wellhead sealing, and cable fixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

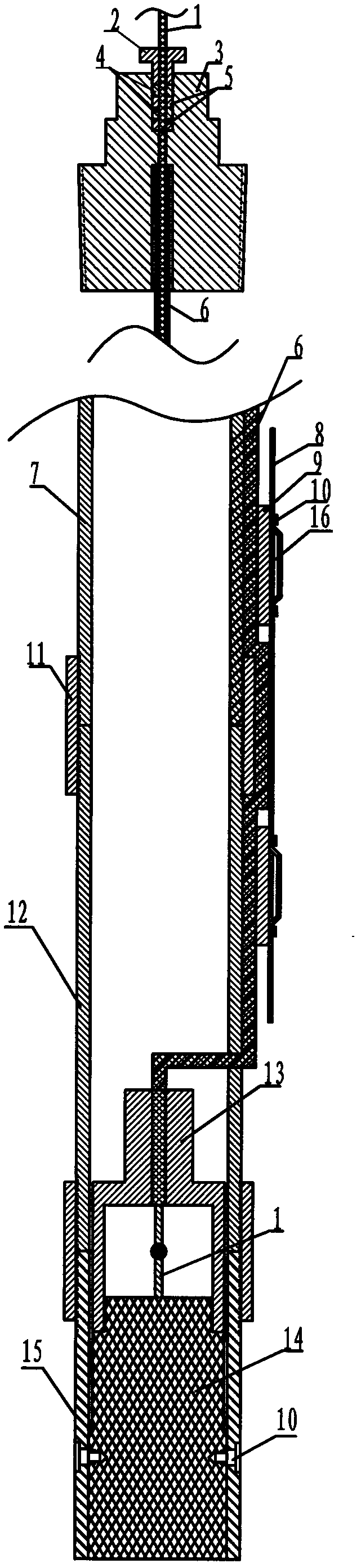

[0006] The following is a further explanation of the present invention based on the drawings (as shown in the figure): The signal transmission method of the downhole measurement and control system uses: cable core 1, pressure cap 2, wire tube 3, spacer 4, sealing ring 5, cable 6 , Oil pipe 7, guard plate 8, rubber protection block 9, screw 10, coupling 11, oil pipe short connection 12, connection and pressure plate 13, sensor 14, protective pipe 15 and steel belt hose clamp 16 for tight connection and sealing completion signal The method of transmission is: the cable or capillary outer armor is closely connected with the oil pipe as the ground wire for signal transmission to complete the single-core transmission signal problem; the uniquely designed connection and pressure plate are used to fix the cable and the sensor, and the protective plate assembly is used And steel belts to fix the cable and the tubing to complete the cable fixation problem; the independently designed line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com