Polymer composite based vacuum forming framework auxiliary device

A composite material and vacuum forming technology, which is applied in separation methods, transportation and packaging, and dispersed particle filtration, etc., can solve problems such as impact, easy to wrinkle on the surface of the membrane, and product quality, so as to improve flexibility, facilitate cleaning, and purify Air Quality Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

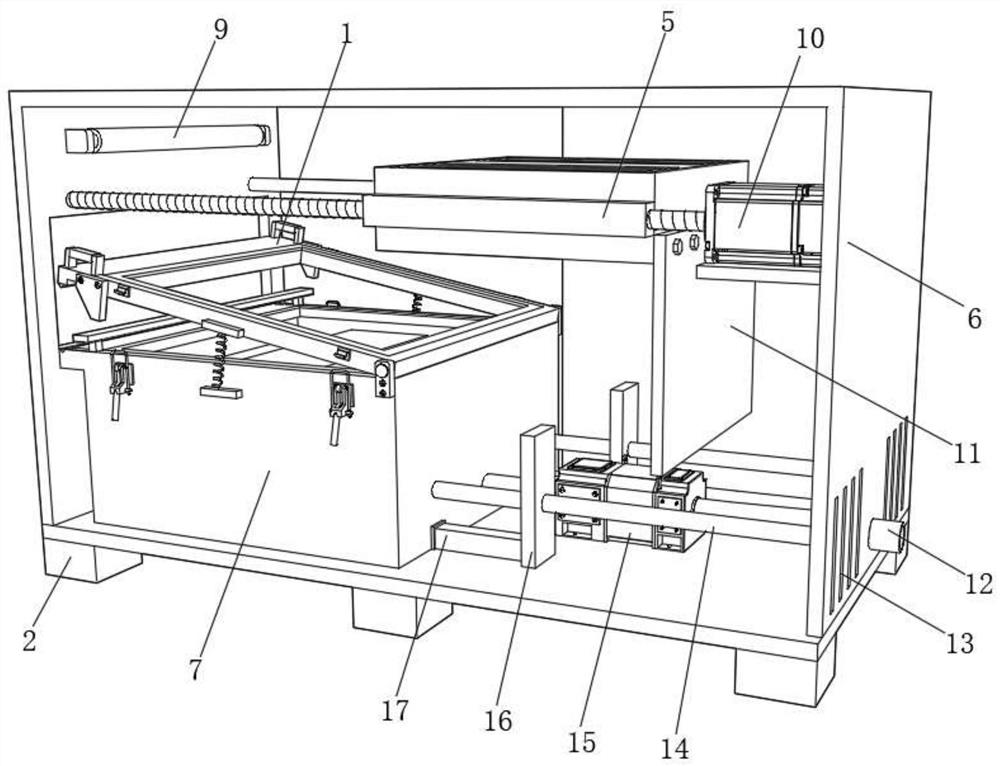

[0034] refer to Figure 1-Figure 6, a vacuum forming framework auxiliary device based on polymer composite materials, including a housing 6, the bottom inner wall of the housing 6 is fixed with a vacuum box 7 by bolts, and two installation grooves are opened on the upper surface of the vacuum box 7, and the inside of the installation groove A fixed sleeve 39 is slidably connected, and one side of the fixed sleeve 39 is fixed with a third spring 38 by bolts, and the other end of the third spring 38 is fixed with a side inner wall of the installation groove by bolts, and the inner sleeve of the fixed sleeve 39 The connecting sleeve 21 is connected, the bottom inner wall of the fixing sleeve 39 is fixed with a fourth spring 40 by bolts, and the other end of the fourth spring 40 is fixed on the inner wall of the top of the connecting sleeve 21 by bolts, and the top of the connecting sleeve 21 is fixed by bolts. A pressing plate 8 is fixed, and a rubber pad 19 is bonded to the bott...

Embodiment 2

[0038] refer to Figure 7 , a vacuum forming framework auxiliary device based on polymer composite materials, also includes a filter mechanism, the filter mechanism includes an installation box 47, and the installation box 47 is connected to the exhaust pipe 12, and the inside of the installation box 47 is slidingly connected with a filter Net frame 46, the top of filter net frame 46 is fixed with cover plate 44 by bolt, and the upper surface of cover plate 44 is fixed with pull handle 45 by bolt, and when air passes through installation box 47 inside, filter net frame 46 can be in the air Impurities are blocked and accumulated inside the filter frame 46, thereby avoiding the direct discharge of the impurities, purifying the air quality of the operating space, and facilitating cleaning of the impurities.

[0039] The working principle of this embodiment: when in use, when the inside of the vacuum box 7 needs to be vacuumed, start the vacuum pump 15, so that the vacuum pump 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com