Demonstration system of industrial robot

A technology of industrial robots and robots, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of high delay between detection servers and databases, and achieve the effects of improving operating efficiency, preventing data loss, and reducing delays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

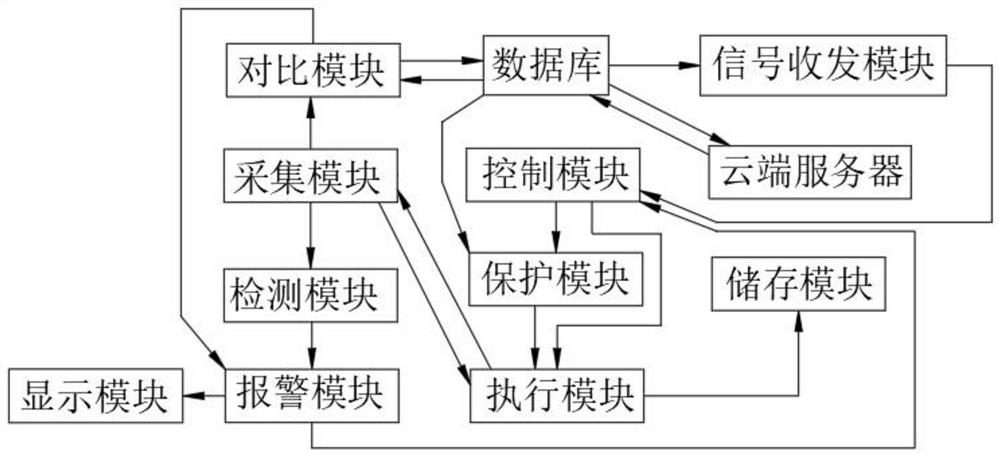

[0037] Such as figure 1 As shown, the embodiment of the present invention provides a teaching system for industrial robots, including a control module, an acquisition module, a detection module, an alarm module, a display module, a comparison module, a database, a signal transceiver module, a cloud server, a protection module, an execution module, a storage module;

[0038] The control module is used to control the whole system;

[0039] The collection module is used to collect robot action features;

[0040] The detection module is used to detect the collected action features;

[0041] The alarm module is used for alarming and reminding when an error occurs;

[0042] The display module is used to display error codes;

[0043] The comparison module is used to compare the detected results with the data in the database;

[0044] The database is used to store the characteristic information of each correct action of the robot;

[0045] The signal transceiver module is used t...

Embodiment 2

[0060] The difference between this embodiment and Embodiment 1 is that when the connection between the teaching pendant and the robot is interrupted, the correct and complete data features in the database cannot be input into the robot’s database at this time, and the correct and complete The data characteristics will be directly sent to the protection module, and then input to the storage module through the execution module for storage and backup, so as to prevent the complete and correct data characteristics in the database from being lost due to input interruption.

Embodiment 3

[0062] The difference between this embodiment and Embodiment 1 is: when the alarm module issues a false alarm but the display module does not display the wrong data feature, the comparison module will compare the collected data feature with the original data feature in the database Upload to the cloud server. At this time, you need to enter the system background to retrieve the data comparison results in the cloud server for analysis, and at the same time check whether there is a problem with the circuit of the display module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com