Superalloy regulator and preparation method thereof

A high-temperature alloy and regulator technology, used in weapon accessories, offensive equipment, etc., can solve the problems of less than 8,000 rounds of service life and low service life, and achieve the effect of improving mechanical performance, improving service life and improving mechanical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-35

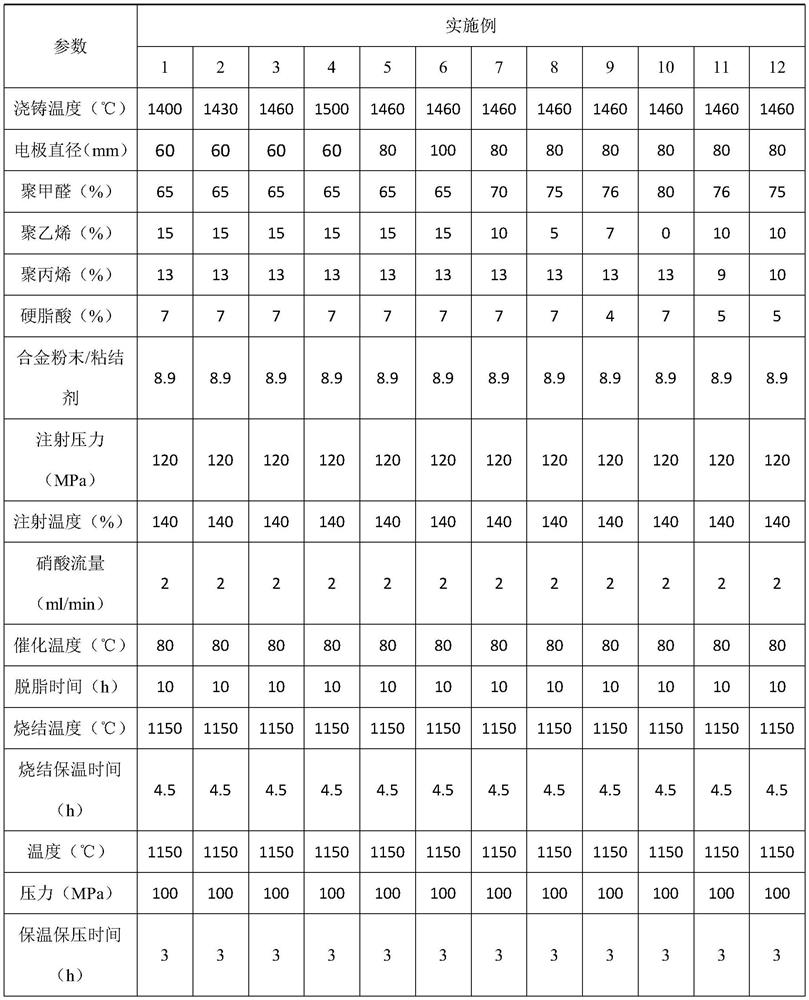

[0063] Examples 1-35 respectively provide the preparation methods of superalloy regulators.

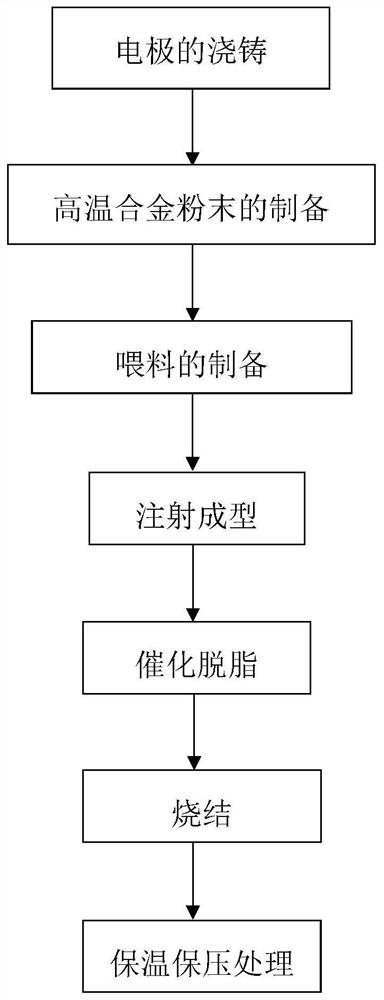

[0064] The preparation method of the superalloy regulator specifically comprises the following steps:

[0065] (1) Electrode casting: use vacuum induction melting technology to cast superalloy to form electrodes;

[0066] (2) Preparation of superalloy powder: using an argon atomization process to make the electrode prepared in step (1) into superalloy powder;

[0067] (3) Preparation of feeding material: uniformly mixing the superalloy powder and binder obtained in step (2) to form feeding material;

[0068] (4) Injection molding: the feeding material prepared in step (3) is placed in a powder injection molding machine, and injected into the mold cavity to form an injection blank;

[0069] (5) catalytic degreasing: carry out nitric acid catalytic degreasing to the injection base that step (4) makes, form the degreasing base;

[0070] (6) Sintering: sintering the degreased body prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com