Electric heating device capable of uniformly and intensively heating

An electric heating device, uniform technology, applied in the direction of ohmic resistance heating parts, heating elements, heating element shape, etc., can solve the problems of low thermal conductivity, high temperature of heating rod, uneven heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

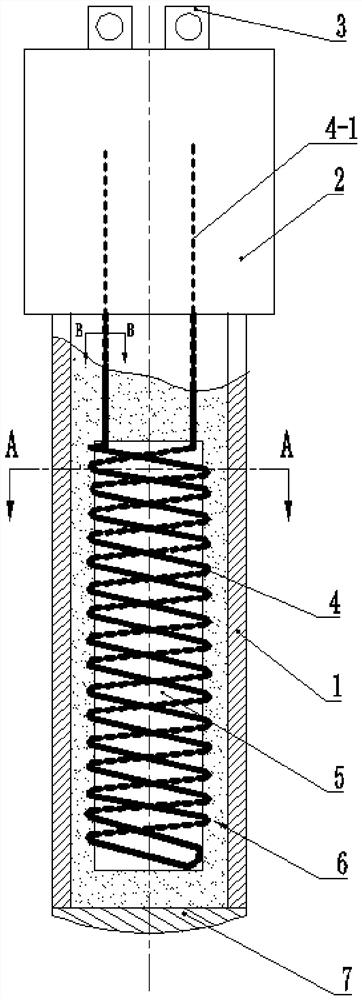

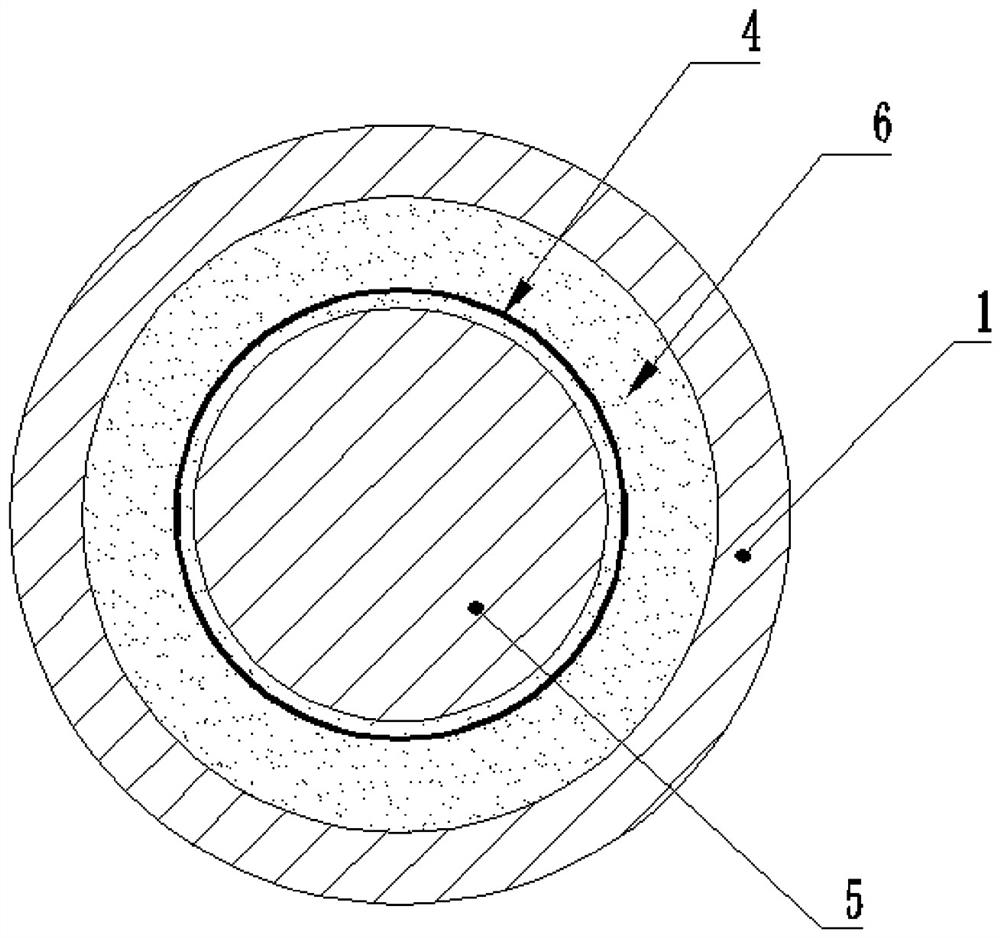

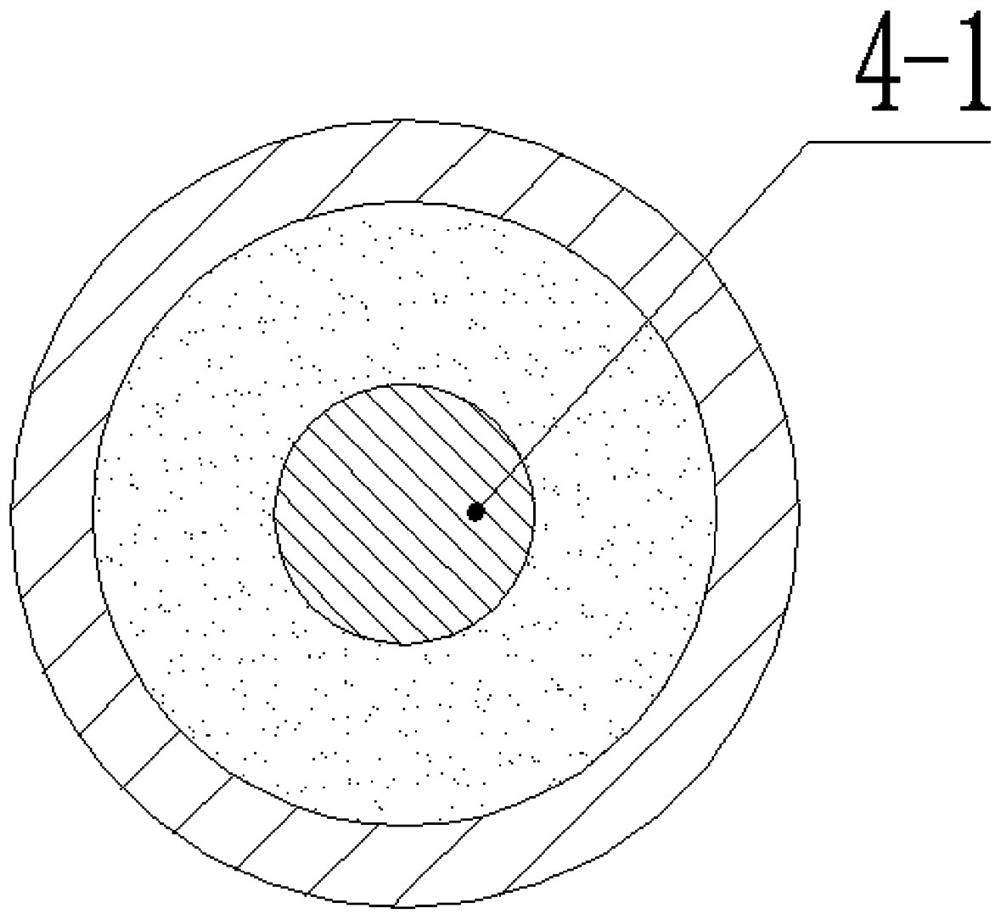

[0019] see Figure 1 to Figure 3 , an electric heating device with uniform and concentrated heating, including a metal shell 1 and a connector, both the metal shell 1 and the connector can be made of stainless steel, the metal shell 1 is sealed at one end, and the other end is fixedly connected with the connector 2. The metal shell 1 and connector 2 can be fixed by welding. The upper end of the connection head 2 is provided with a connection terminal 3, which is used for connecting with an external power supply and can be fixed on the upper end of the connection head by epoxy resin. The metal shell 1 is provided with an axially extending metal heat collecting mandrel 5. The metal heat collecting mandrel 5 is made of copper rod, silver rod or nickel rod. The metal mandrel with equal thermal conductivity is used as the metal heat collecting mandrel 5, so that the heat generated by the armored heating cable 4 can be quickly and evenly transferred to the metal heat collecting man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com