Glass fiber reinforced plastic optical cable protection bushing

A technology of reinforced plastic and glass fiber, used in optical fiber/cable installation, cable installation, cable installation in underground pipes, etc., can solve the problem of no external shock, no internal moisture absorption, no internal cable Lifting and fixing problems, to achieve the effect of convenient interface sealing, reducing contact surface and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

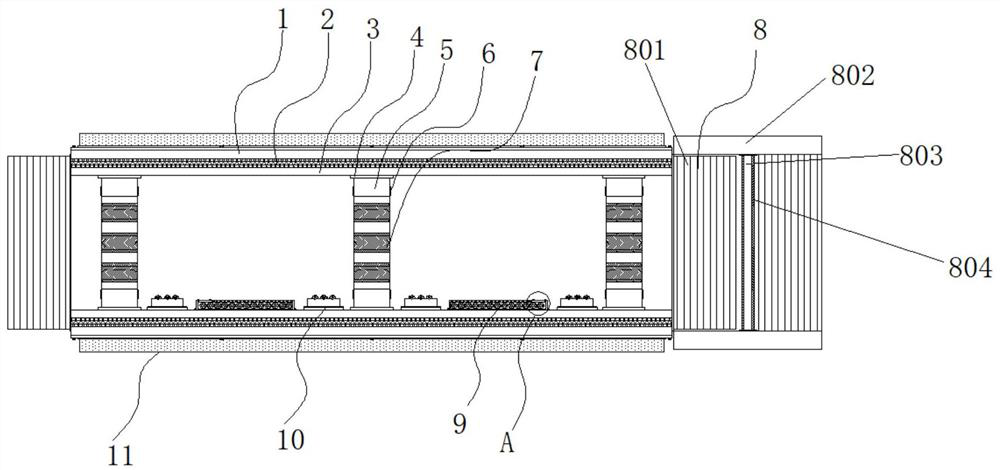

[0035] Example 1: See Figure 1-6 , a glass fiber reinforced plastic optical cable protective sleeve, comprising an outer tube 1, an inner tube 3 is arranged inside the outer tube 1, a glass fiber layer 2 is fixedly connected between the outer tube 1 and the inner tube 3, and the inner tube 3 There are three sets of fixed line support structures inside;

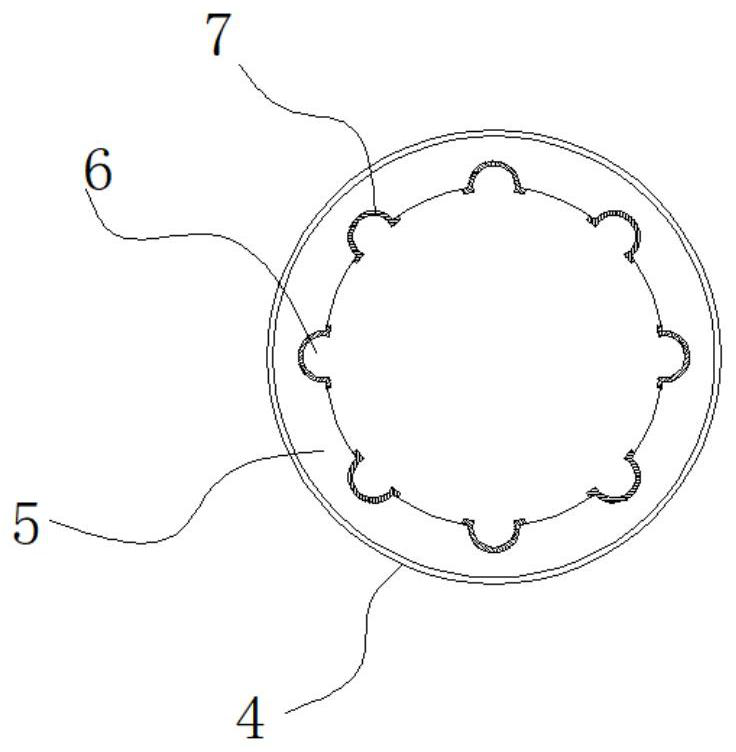

[0036] see Figure 1-6 , a glass fiber reinforced plastic optical cable protective sleeve also includes a fixed line support structure, the fixed line support structure includes a fixed ring 4, the fixed ring 4 is fixedly connected to the inside of the inner tube 3, and the inside of the fixed ring 4 is fixedly connected with a soft The rubber ring 5, the inside of the soft rubber ring 5 is provided with multiple sets of wire grooves 6, and the inside of the wire groove 6 is sleeved with an anti-wear sleeve 7;

[0037] The slots 6 are arranged at equal intervals, and the outer diameter of the fixed ring 4 is consistent with...

Embodiment 2

[0039] Embodiment 2: One side of the outer tube 1 is provided with a sealing structure 8 for the connecting port. The sealing structure 8 for the connecting port is composed of a connecting head 801, a connecting ring 802, a fixed ring 803 and a silicone ring 804. The connecting head 801 is fixedly connected to the outer tube 1. On one side, the external thread of the connector 801 is connected with a connecting ring 802, the middle position inside the connecting ring 802 is fixedly connected with a fixed ring 803, and the two sides of the connecting ring 802 are fixedly connected with a silicone ring 804;

[0040] The external threads of the connector 801 and the internal threads of the connecting ring 802 coincide with each other, and the silicone ring 804 is symmetrically distributed about the vertical center line of the fixed ring 803;

[0041] Specifically, such as figure 1 and Figure 4 As shown, the connecting ring 802 is put on the outside of the connecting head 801, ...

Embodiment 3

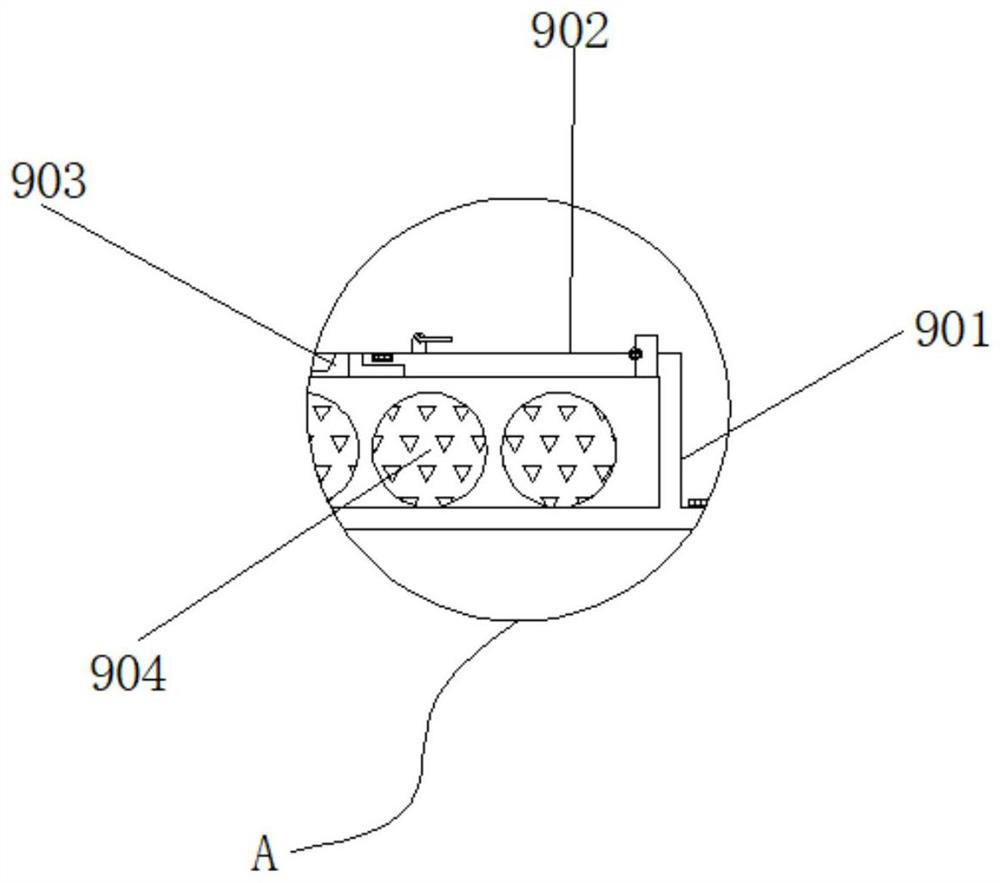

[0042] Embodiment 3: Two sets of internal moisture absorbing structures 9 are provided at the bottom of the inner tube 3. The internal moisture absorbing structures 9 are composed of a box body 901, a refueling door 902, a through plate 903 and a color-changing silica gel 904. The box body 901 It is fixedly connected to the bottom end inside the inner tube 3, and the inside of the box body 901 is provided with multiple sets of color-changing silica gel 904, and one side of the top of the box body 901 is movably hinged with a refueling door 902, and the inside of the top of the box body 901 is provided with a through plate 903 ;

[0043] Small holes are evenly arranged inside the through plate 903, and the color-changing silica gel 904 is arranged at equal intervals;

[0044] Specifically, such as figure 1 and image 3 As shown, when there is moisture accumulation inside the pipeline, the external humid air enters the inside of the box body 901 through the small hole on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com