Ceramic vacuum pump

A ceramic vacuum and pump casing technology, applied in the direction of pumps, pump devices, pump components, etc., can solve problems such as poor heat dissipation performance, and achieve the effects of reducing vibration, increasing service life, and good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

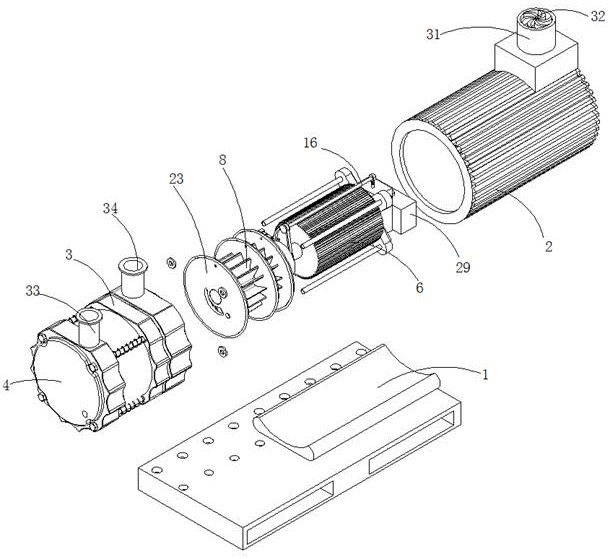

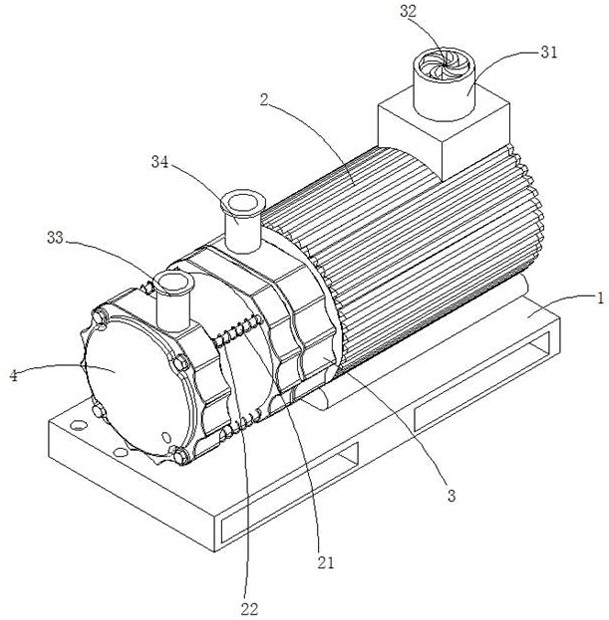

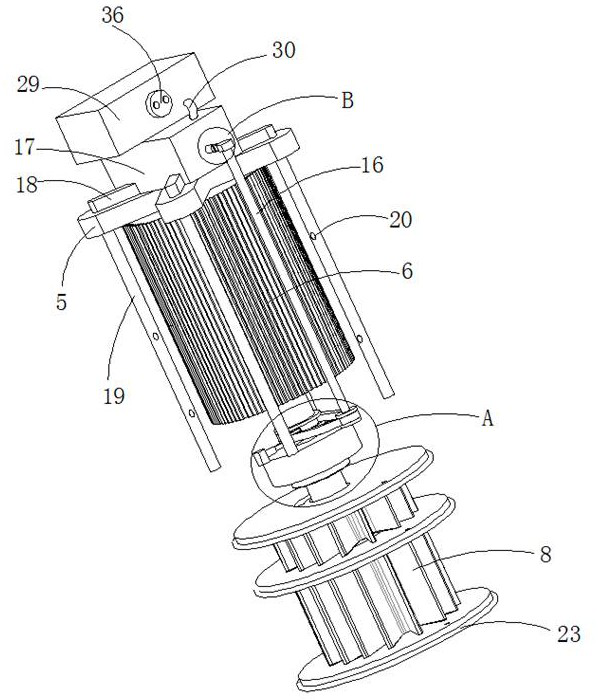

[0032] refer to Figure 1-6 , a ceramic vacuum pump, including a base 1, a pump casing and a motor casing 2, the pump casing and the motor casing 2 are sequentially arranged on the top of the base 1 along the horizontal direction, the pump casing includes a casing 3 and a casing cover 4, and the pump casing 3 The inner wall of the shell and the inner end surface of the shell cover 4 are sprayed with a ceramic coating with a thickness of 0.3 mm to 0.5 mm. The shell cover 4 is detachably connected to the opening of the shell 3 away from the motor shell 2. The shell 3 and the motor shell 2 are fixedly connected, the drive motor 6 is installed in the motor shell 2 through the X-shaped bracket 5, the drive end of the drive motor 6 is connected with the drive shaft 7, and the end of the drive shaft 7 away from the drive motor 6 extends to the inner cavity of the shell 3, and the transmission The extension end of the shaft 7 is eccentrically arranged in the inner cavity of the casing...

Embodiment 2

[0042] refer to Figure 1-2 , a ceramic vacuum pump, which is basically the same as in Embodiment 1, furthermore, the shell cover 4 and the shell 3 are provided with threaded mounting holes that cooperate with each other, and the threaded mounting holes on the shell 3 are threadedly connected with a connecting rod 21, and the connecting rod 21 The end away from the housing 3 is threadedly connected to the housing cover 4, and a tension spring 22 sleeved on the outer wall of the connecting rod 21 is fixedly connected between the housing 3 and the housing cover 4. The tension spring 22 helps to reduce the vacuum pump when it is working. vibration, while improving the tightness of the connection between the case cover 4 and the housing 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com