Pseudo soldering detection method, pseudo soldering detection device and preparation method of lithium battery

A detection method and detection device technology, applied in the direction of measuring devices, mechanical devices, optical devices, etc., can solve the problems of large fluctuations in manufacturing processes and raw materials, poor welding of pole pieces and tabs, and prone to false welding, etc. Achieve the effect of avoiding waste of materials and manpower, high applicability, and avoiding contact damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

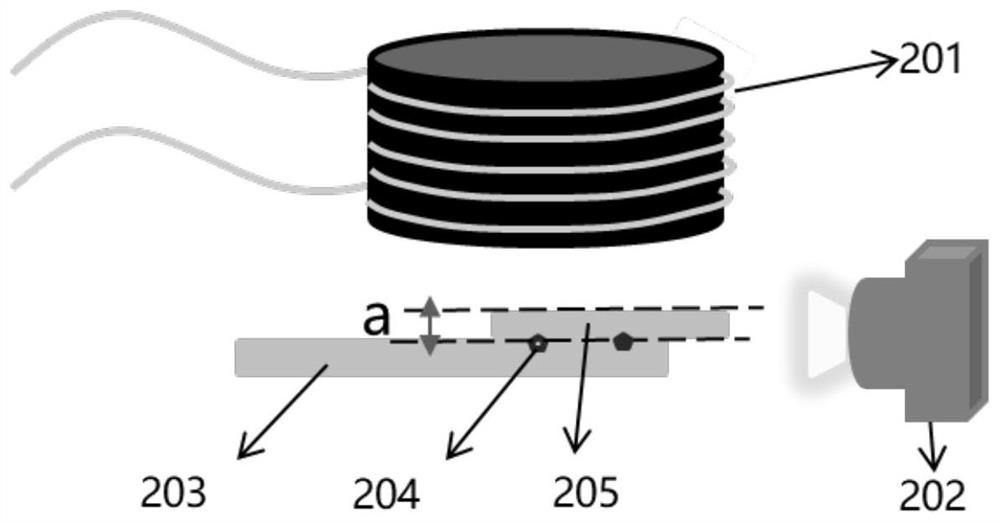

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings. When describing the embodiments of the present invention in detail, for the convenience of explanation, the accompanying drawings showing the structure of the device will not be partially enlarged according to the general scale, and the schematic diagram is only an example, and it should not be limited here. The protection scope of the present invention. It should be noted that all the drawings are in very simplified form and use imprecise scales, which are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

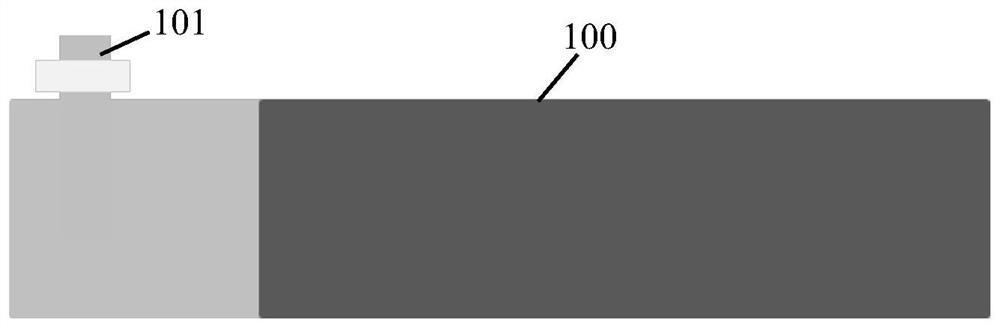

[0024] like figure 1 As shown, the lithium battery pole piece generally includes a pole piece current collector 100, the pole piece current collector 100 is coated with a paste, and one end of the pole piece current collector 100 retains an empty foil that is not coated with paste, and the tab 101 (No. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com