High-temperature-resistant battery diaphragm with anti-wrinkle characteristic, and preparation method and application of high-temperature-resistant battery diaphragm

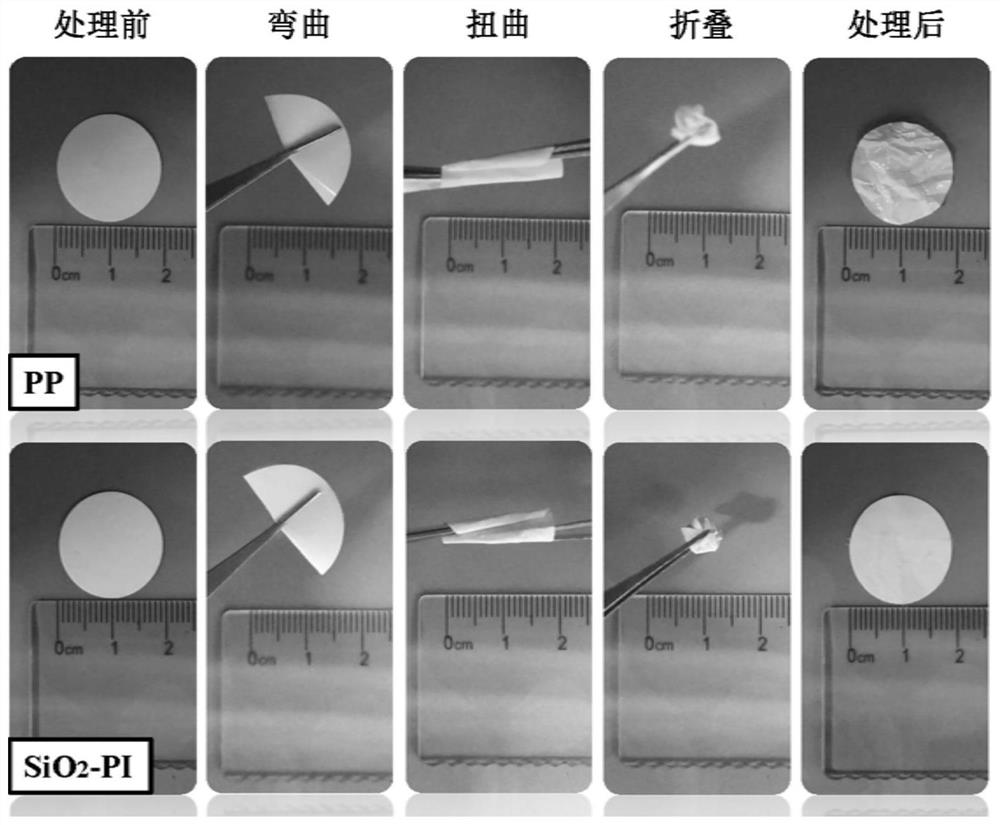

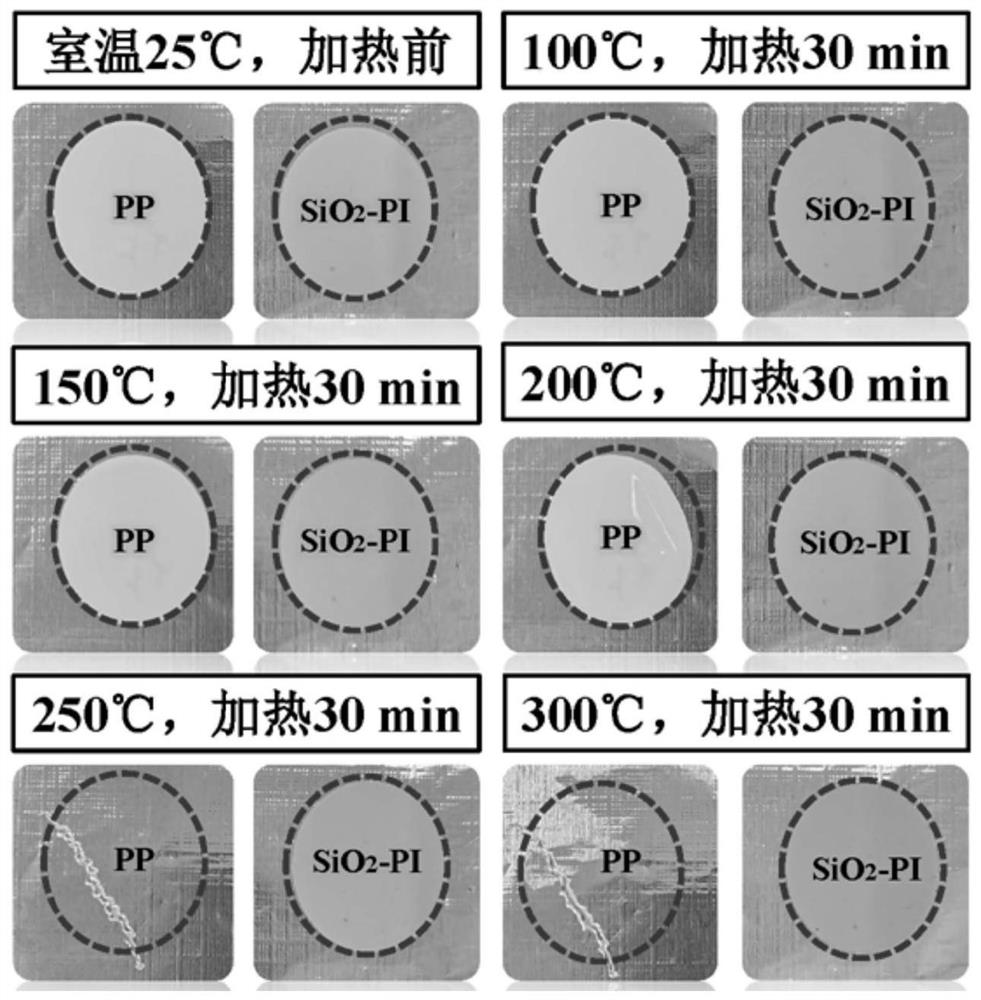

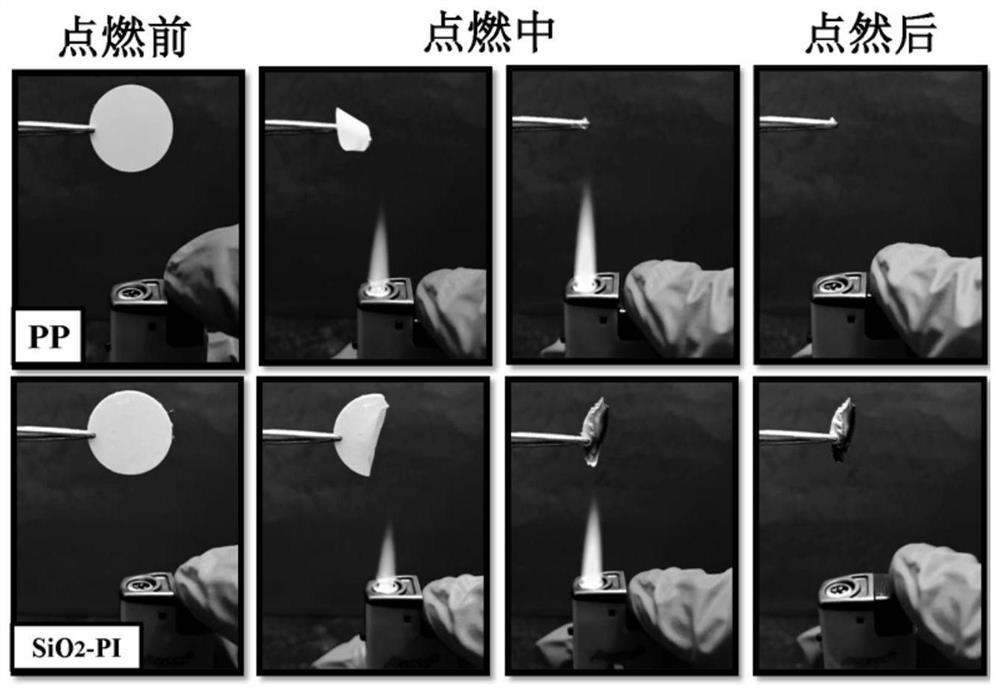

A high-temperature-resistant battery separator technology, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as poor wettability of electrolyte, poor battery safety and electrochemical performance, and easy wrinkles. Achieve the effect of excellent electrochemical performance and excellent electrolyte wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A high-temperature-resistant battery separator with anti-wrinkle properties, the specific preparation method is as follows:

[0047]S1. Preparation of spinning solution: Weighing 0.020mol of diamine monomer (diaminodiphenyl ether) into a 250mL three-necked flask, then adding 50mL of N,N-dimethylformamide solution (DMF), at 0 ℃ under the condition of ice-water bath and continuous feeding of argon protection, stirring for 2h, after it is completely dissolved, add 0.020mol of dianhydride monomer (biphenyltetracarboxylic dianhydride) in three times at 30min / time, in ice bath condition Continue to stir 4h down, obtain polyamic acid (PAA) viscous pale yellow solution, the inorganic nano material SiO that massfraction is 10% 2 Disperse in 25mL of DMF solution, ultrasonic 2h to make it evenly dispersed, the uniformly dispersed SiO 2 The solution was added to the PAA solution and stirred rapidly for 2h to obtain SiO 2 - PAA spinning solution;

[0048] S2. Preparation of SiO b...

Embodiment 2

[0051] A method for preparing a high-temperature-resistant battery separator with anti-wrinkle properties, the specific preparation method is as follows:

[0052] S1. Preparation of spinning solution: Weighing 0.020mol of diamine monomer (diaminodiphenyl ether) into a 250mL three-necked flask, then adding 50mL of N,N-dimethylformamide solution (DMF), at 0 ℃ under the condition of ice-water bath and continuous feeding of argon protection, stirring for 2h, after it is completely dissolved, add 0.020mol of dianhydride monomer (biphenyltetracarboxylic dianhydride) in three times at 30min / time, in ice bath condition Continue to stir 4h down, obtain polyamic acid (PAA) viscous pale yellow solution, the inorganic nano material SiO that massfraction is 1% 2 Disperse in 25mL of DMF solution, ultrasonic 2h, make it evenly dispersed, the uniformly dispersed SiO 2 The solution was added to the PAA solution and stirred rapidly for 2h to obtain SiO 2 - PAA spinning solution;

[0053] S2....

Embodiment 3

[0056] A high-temperature-resistant battery separator with anti-wrinkle properties, the specific preparation method is as follows:

[0057] S1. Preparation of spinning solution: Weighing 0.020mol of diamine monomer (diaminodiphenyl ether) into a 250mL three-necked flask, then adding 50mL of N,N-dimethylformamide solution (DMF), at 0 ℃ under the condition of ice-water bath and continuous feeding of argon protection, stirring for 2h, after it is completely dissolved, add 0.020mol of dianhydride monomer (biphenyltetracarboxylic dianhydride) in three times at 30min / time, in ice bath condition Continue to stir 4h down, obtain polyamic acid (PAA) viscous pale yellow solution, the inorganic nano material SiO that massfraction is 20% 2 Disperse in 25mL of DMF solution, ultrasonic 2h, make it evenly dispersed, the uniformly dispersed SiO 2 The solution was added to the PAA solution and stirred rapidly for 2h to obtain SiO 2 - PAA spinning solution;

[0058] S2. Preparation of spun f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com