Gas leakage detection device for natural gas pipeline transportation

A technology of natural gas pipelines and detection devices, which is applied in the direction of measuring devices, pipeline systems, pipe components, etc., can solve problems such as gas leakage, achieve the effects of avoiding gas leakage, improving efficiency and accuracy, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

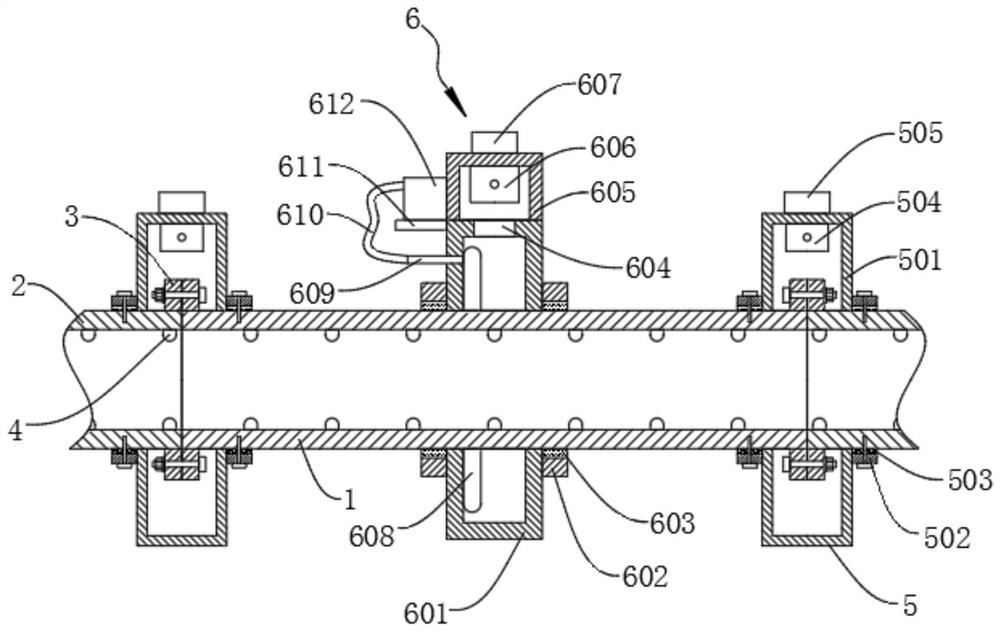

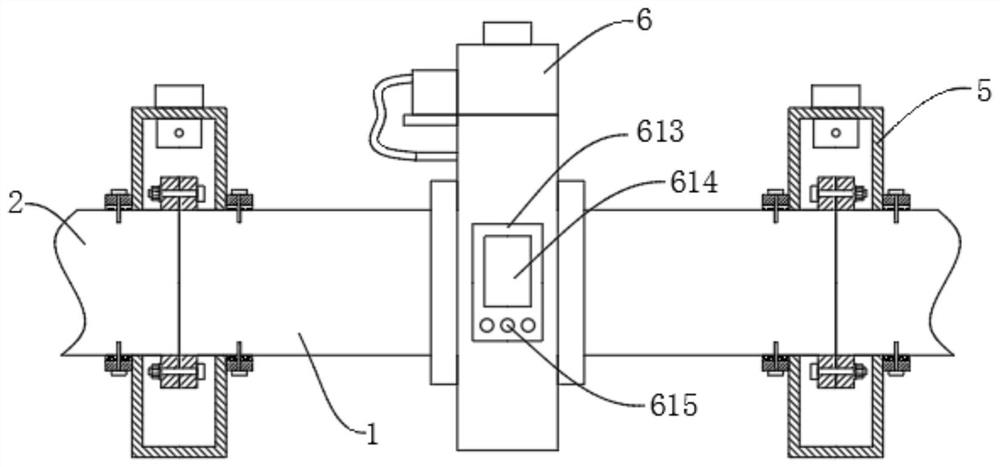

[0025] refer to Figure 1-5 , a gas leakage detection device for natural gas pipelines, comprising a first gas pipeline 1 and two second gas pipelines 2, the two second gas pipelines 2 communicate with the two ends of the first gas pipeline 1, the first Flange pieces 3 are fixedly connected between the two ends of the gas pipeline 1 and the opposite ends of the two second gas pipelines 2, and the two second gas pipelines 2 are fixedly connected to the first through the flange pieces 3. Both ends of the gas transmission pipeline 1 can communicate with each other between the second gas transmission pipeline 2 and the first gas transmission pipeline 1 through the flange piece 3 .

[0026] A plurality of pressure sensors 4 are fixedly connected to the inner walls of the first gas transmission pipeline 1 and the two second gas transmission pipelines 2, and the plurality of pressure sensors 4 are arranged at equal intervals between the first gas transmission pipeline 1 and the two s...

Embodiment 2

[0031] refer to figure 1 , figure 2 and Figure 4, as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the first air leakage detection mechanism 5 includes a first collection cover 501, and the first collection cover 501 is fixedly connected to the first gas pipeline 1 through a fixing mechanism. The opposite end of the second gas transmission pipeline 2, and the first collection cover 501 is sleeved on the outside of the flange plate 3, and the first natural gas detector 504 is fixedly connected to the inner wall of the first collection cover 501. The first collection cover The outer wall of 501 is fixedly connected with a first alarm device 505, and the fixing mechanism includes four fixing clips 502, and the four fixing clips 502 are respectively fixedly connected to both sides of the two first collection covers 501, and the four fixing clips The clips 502 are respectively fixedly connected to the outer walls of the first ga...

Embodiment 3

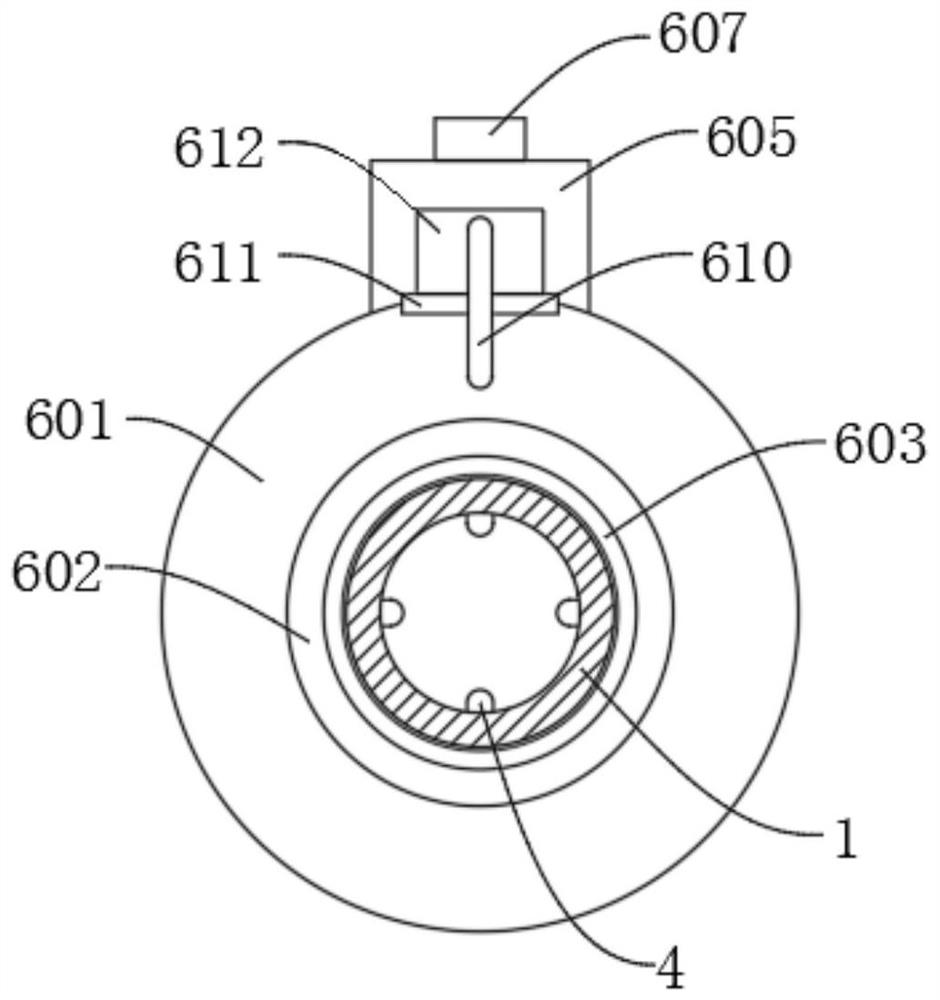

[0033] refer to figure 1 , figure 2 and image 3 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the second air leakage detection mechanism 6 includes a second collection cover 601, and the second collection cover 601 is slidably sleeved on the first gas pipeline 1 On the outer wall of the second collection cover 601, the two sides of the second collection cover 601 are respectively fixedly connected with connecting sleeves 602, and the two connecting sleeves 602 are respectively slidably sleeved on the outer wall of the first gas pipeline 1, and the connecting sleeves 602 A second sealing layer 603 is fixedly connected to the inner side wall of the first gas pipeline 1, and the second sealing layer 603 is connected to the outer side wall of the first gas pipeline 1 in a dynamic sealing manner.

[0034] The side wall of the second collection cover 601 is penetrated with an air vent 604, and the outer wall of the second co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com