Low-position grouting and filling method for gangue slurry on coal face

A coal mining face and working face technology, which is applied to filling materials, mining equipment, earth cube drilling, etc., can solve the problems of reducing the amount of gangue slurry filling, reducing the filling efficiency of gangue slurry, and reducing the diffusion range, etc., to achieve Avoid disassembly and installation procedures, improve layout efficiency, and reduce the effect of constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

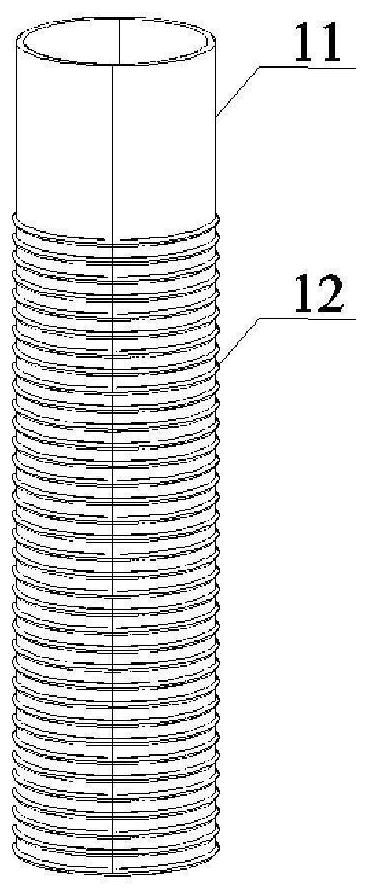

[0034] The invention provides a low-level grouting filling method of gangue slurry in a coal mining face, which is suitable for filling gobs in coal mining faces of various gently inclined coal seams, such as figure 1 As shown, the method includes arranging low-level grouting pipes and low-level grouting main valves 9 respectively in the auxiliary transport roadway 2 of the coal mining face 3 and the goaf behind the coal mining face 3; wherein the low-level grouting pipes adopt flexible grouting The low-level grouting pipe includes the low-level grouting pipe 6 of the auxiliary transportation roadway, the low-level grouting pipe 8 of the goaf and the low-level grouting main pipe 10; The grouting pipe 8 is connected; the low-level grouting main pipe 10 is provided with a low-level grouting mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com