A multi-directional self-moving arch anti-shock advance hydraulic support

A hydraulic support and self-moving technology, which is applied to the mine roof support, mechanical equipment, vibration suppression adjustment, etc., can solve the problem that the self-moving advanced hydraulic support occupies a large space, the crawler-type advanced hydraulic support is difficult to turn, and cannot guarantee work. Face safety production and other issues, to achieve the effect of easy safety maintenance, compact structure and good shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further explained and described below through specific embodiments.

[0041] In the description of the present invention, it should be noted that the longitudinal direction is the direction parallel to the axial direction of the roadway. The term "connection" should be understood in a broad sense, for example, it may be a fixed connection, a detachable connection, or an integral connection; it may be a mechanical connection or an electrical connection; it may be indirectly connected through an intermediate medium, or two Connectivity within the element. For those of ordinary skill in the art, the specific meanings of the above terms in the present invention can be understood in specific situations.

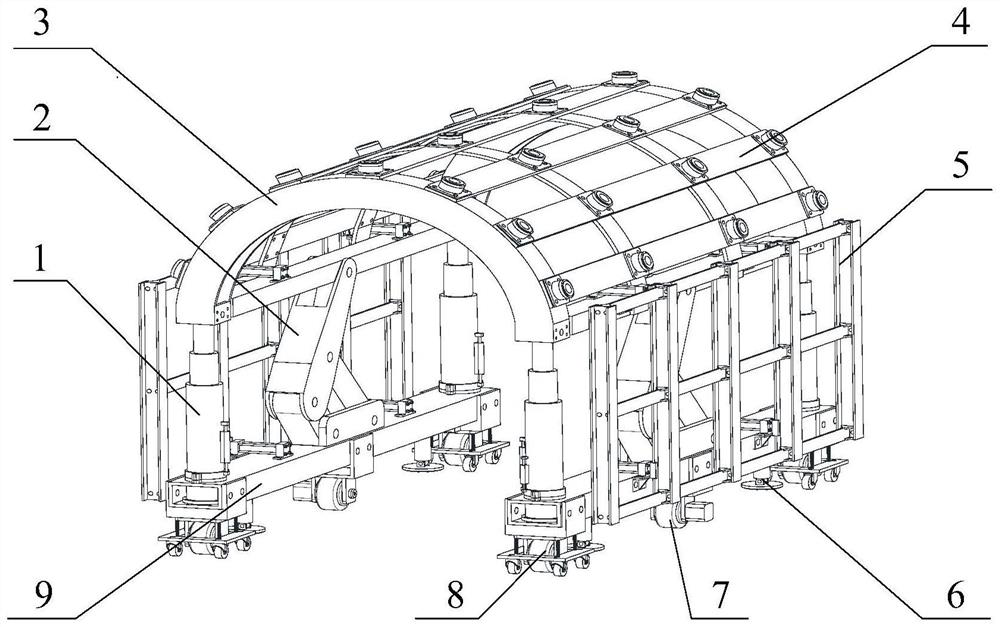

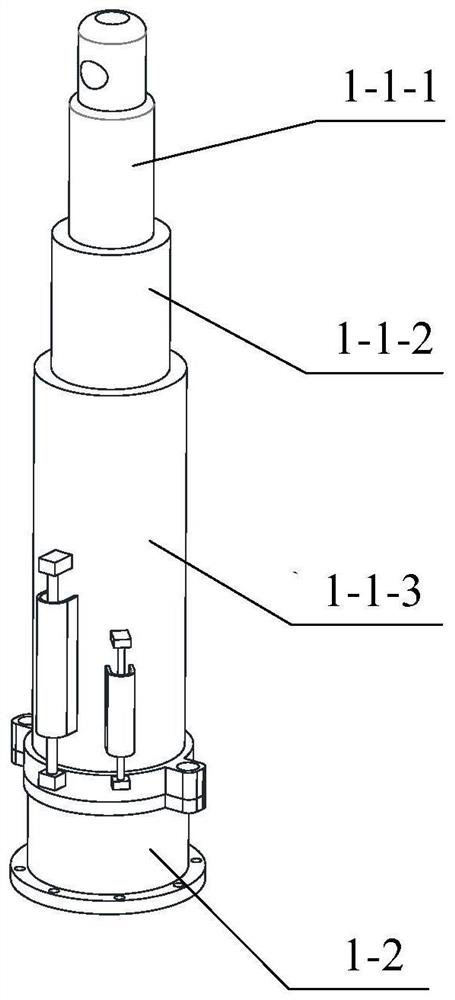

[0042] like figure 1 As shown, it is a schematic structural diagram of a multi-directional self-moving arch anti-shock advance hydraulic support when walking, including a double telescopic column assembly 1, a supporting beam assembly 2, an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com